Absorber with steel strip winding structure and preparation method

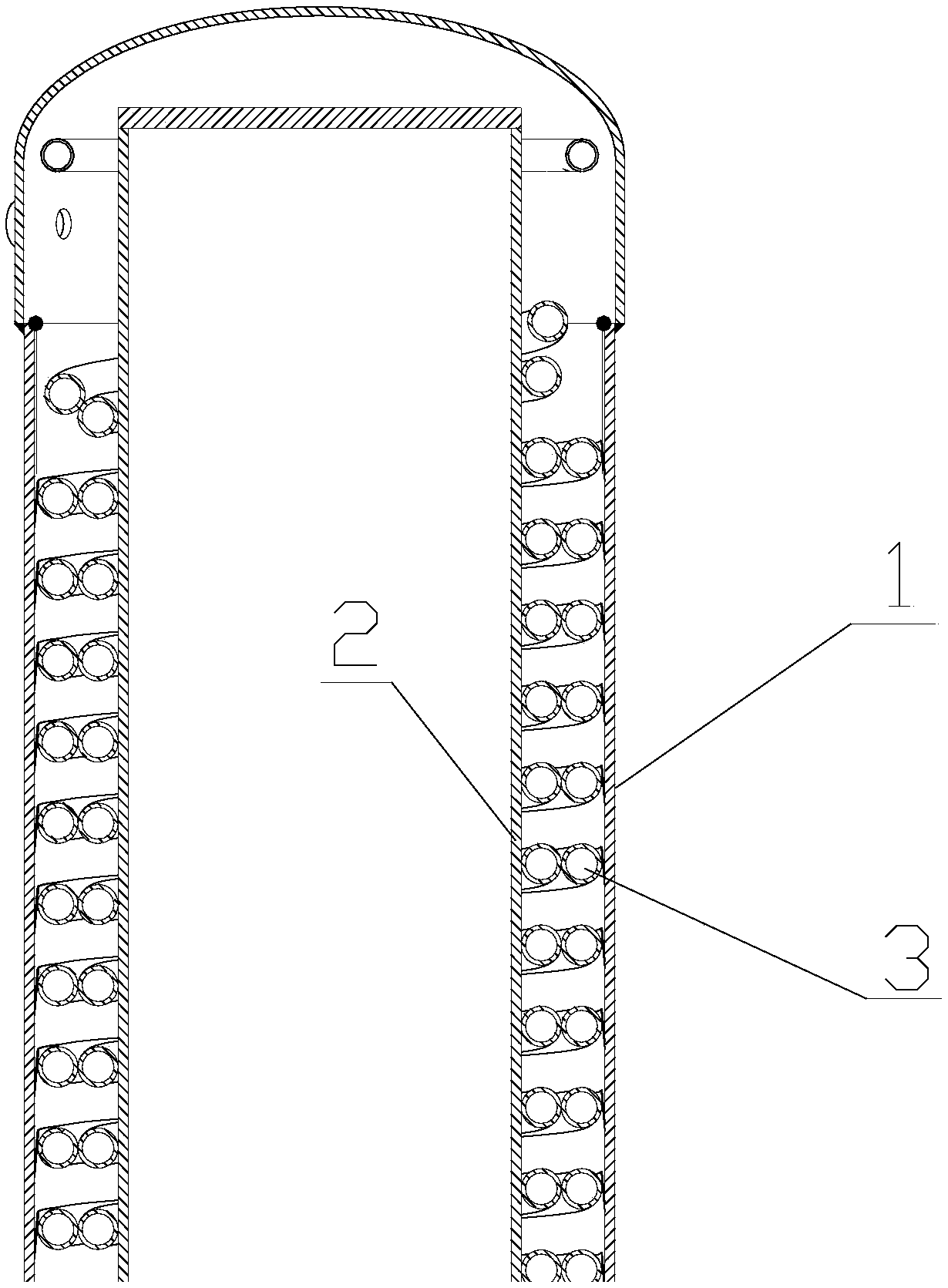

A technology of absorber and steel belt, which is applied in the direction of absorbent/adsorbent, refrigerator, refrigeration components, etc., can solve the problems of solution flow and decrease of absorber absorption efficiency, and achieve simple operation, improved absorption efficiency and repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The material of the steel strip used in this embodiment is stainless steel, the thickness of the steel strip is 2mm, and the width is 40mm.

[0037] A method for preparing an absorber with a steel strip winding structure, comprising the following steps:

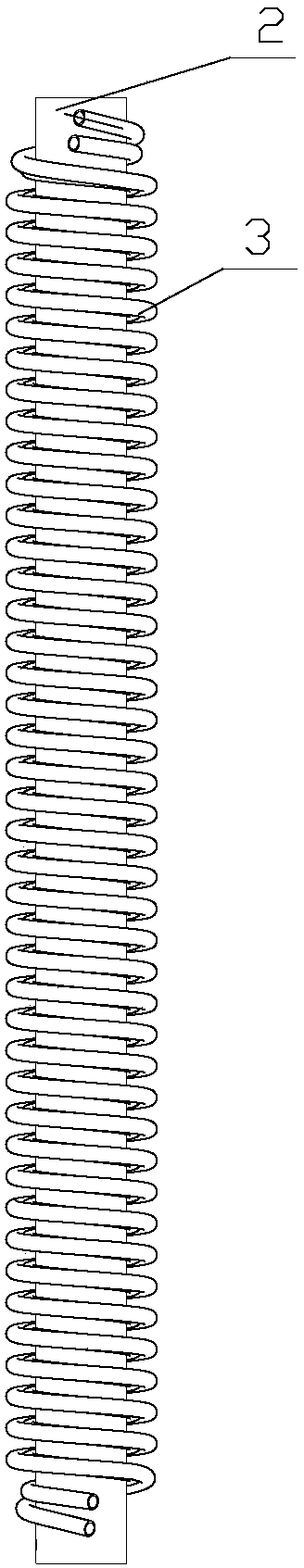

[0038] (1) Wrap the spiral tube on the surface of the inner tube of the absorber to obtain a winding structure, such as figure 2 shown;

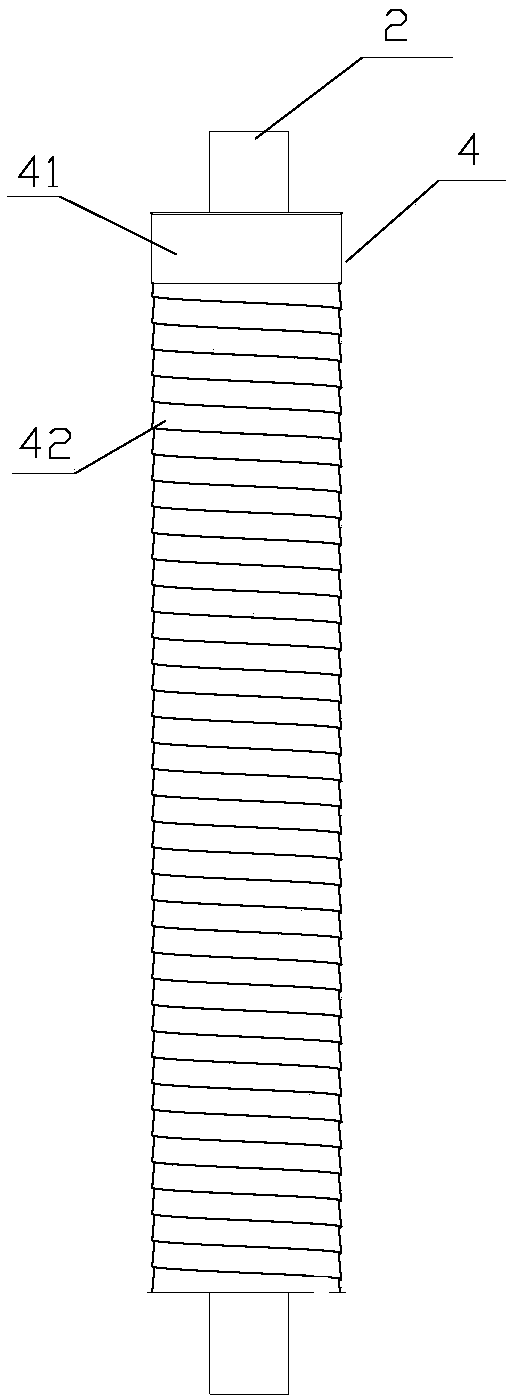

[0039] (2) Wrap the steel strip on the outside of the winding body structure with a winding force of 1000N. During the winding process, first wind the steel strip on the top of the winding body structure to form a steel strip with a thickness of 3mm and a width of 80mm (such as image 3 Winding structure 41) at the end of the middle steel strip, and then continue winding to ensure that two adjacent circles of steel strips overlap each other, and the overlapping width is 20mm (such as image 3 Middle steel strip winding structure 42); during the winding process, the steel strip and...

Embodiment 2

[0043] The material of the steel strip used in this embodiment is stainless steel, the thickness of the steel strip is 1mm, and the width is 40mm.

[0044] A method for preparing an absorber with a steel strip winding structure, comprising the following steps:

[0045] (1) Wrap the spiral tube on the surface of the inner tube of the absorber to obtain a winding structure, such as figure 2 shown;

[0046] (2) Wrap the steel strip on the outside of the winding body structure with a winding force of 50N. During the winding process, first wind the steel strip on the top of the winding body structure to form a steel strip with a thickness of 1.5mm and a width of 45mm (such as image 3 Winding structure 41) at the end of the middle steel strip, and then continue winding to ensure that two adjacent circles of steel strips overlap each other, and the overlapping width is 15mm (such as image 3 Intermediate section winding structure of the steel strip 42); during the winding process, ...

Embodiment 3

[0050] The material of the steel strip used in this embodiment is stainless steel, the thickness of the steel strip is 0.01mm, and the width is 40mm.

[0051] A method for preparing an absorber with a steel strip winding structure, comprising the following steps:

[0052] (1) Wrap the spiral tube on the surface of the inner tube of the absorber to obtain a winding structure, such as figure 2 shown;

[0053] (2) Wrap the steel strip on the outside of the winding body structure with a winding force of 15N. During the winding process, first wind the steel strip on the top of the winding body structure to form a steel strip with a thickness of 0.5mm and a width of 80mm (such as image 3 Winding structure 41) at the end of the middle steel strip, and then continue winding to ensure that two adjacent circles of steel strips overlap each other, and the overlapping width is 20mm (such as image 3 Middle steel strip winding structure 42); during the winding process, the steel strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com