High-temperature medium pressure pipeline blocking device

A technology for pressure pipelines and plugging devices, which is applied in the direction of pipe components, pipeline systems, pipes/pipe joints/pipe fittings, etc. good question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

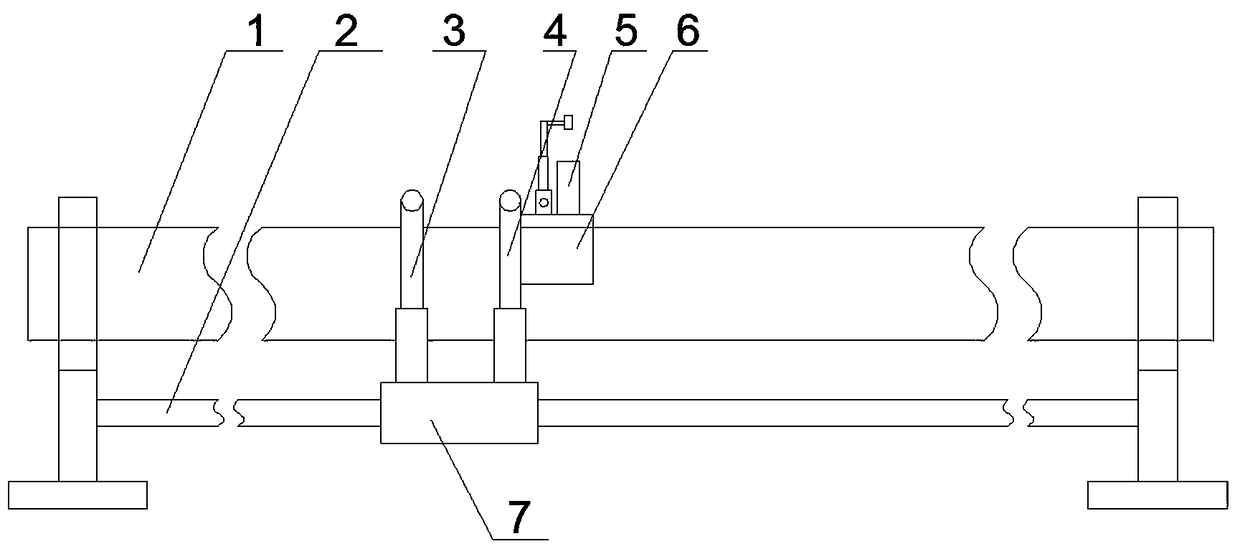

[0064] A high-temperature medium pressure pipeline plugging device, comprising a traveling mechanism 7 arranged on a fixed base at the end of a pressure pipeline 1, an inspection mechanism 3 arranged on the traveling mechanism 7, and an inspection mechanism 3 arranged on the traveling mechanism The blocking mechanism 4 on the 7 and matched with the inspection mechanism 3, and the control mechanism arranged on the running mechanism 7 for controlling the running mechanism 7, the inspection mechanism 3 and the blocking mechanism 4;

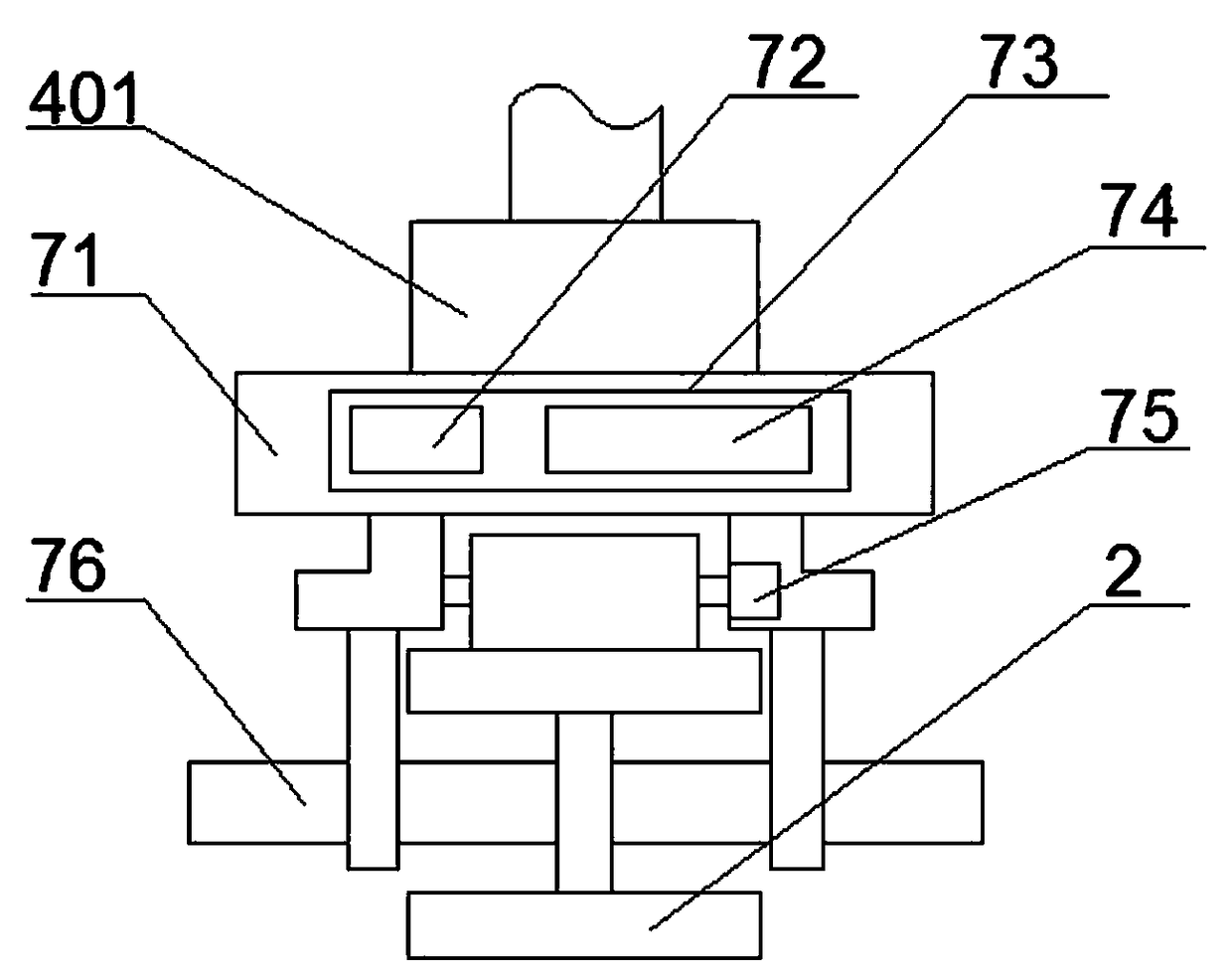

[0065] The traveling mechanism 7 includes a traveling track 2 connected to the fixed base of the pressure pipeline 1, a traveling trolley 71 arranged on the traveling trolley 2, arranged on the lower part of the traveling trolley 71 and opposite to the traveling rail 2. A plurality of driving wheels 76 matched, a driving motor 75 matched with the driving wheels 76 , a cooling mechanism arranged on the walking trolley, and the control mechanism arrange...

Embodiment 2

[0080] The difference from Embodiment 1 is that: a sealing ring matching with the upper end of the sealing tube 5 is provided on the peripheral side of the operation boss 414 .

[0081] It is arranged on the blocking support plate 409 and a multi-layer sealing ring 417 is arranged around the blocking hole 423 .

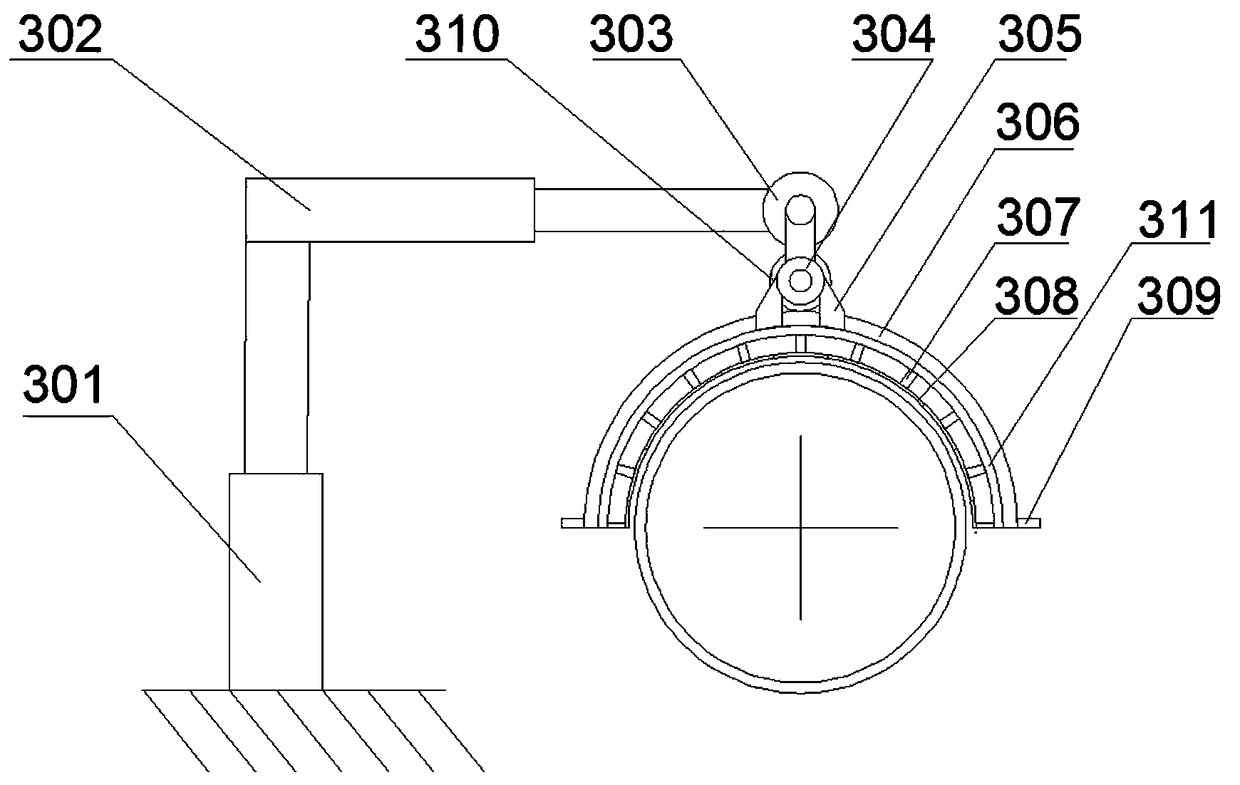

[0082] The radius value of the circle where the arc-shaped blocking guide rail 306 and the arc-shaped inspection guide rail 408 are located is greater than the radius value of the circle on the outer wall of the cross-section of the pressure pipe 1 .

[0083] The arc formed by the arc-shaped blocking guide rail 306 and the arc-shaped inspection guide rail 408 is a semi-circular arc.

[0084] The threaded surface of the sealing plug 4223 is provided with a graphite sealing coating.

Embodiment 3

[0086] The difference from the first embodiment is that the first driving wheel 310 is a helical gear.

[0087] The threaded surface of the sealing plug 4223 is provided with a layer of sealing tape wrapped around it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com