Vehicle dynamic weighing compensation sensor array, system and method

A compensation sensor, dynamic weighing technology, applied in the direction of weighing equipment testing/calibration, detailed information of weighing equipment, instruments, etc., can solve problems such as weight data reduction, and achieve the effect of avoiding abnormal situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

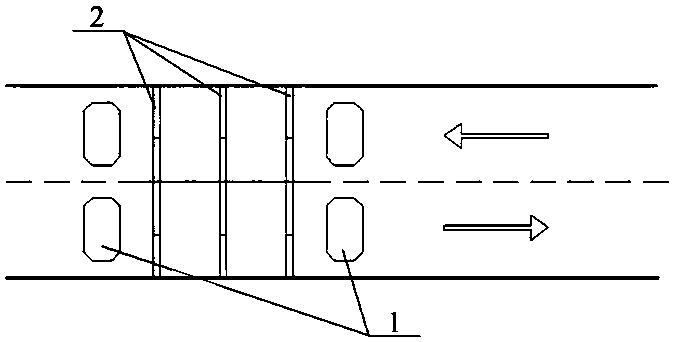

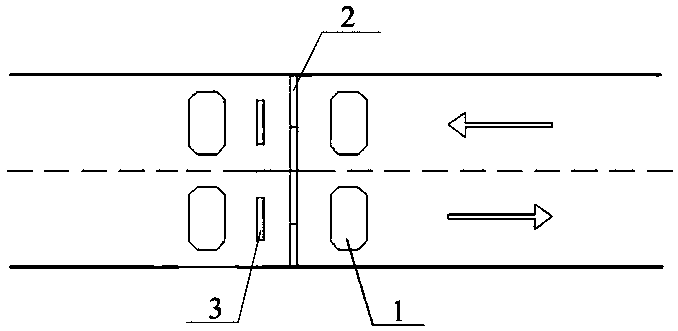

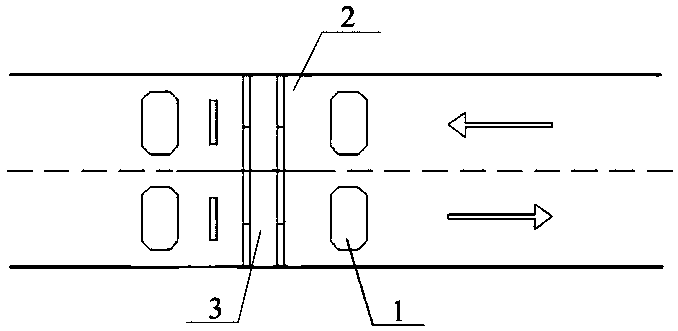

[0050] Further describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0051] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a vehicle dynamic weighing compensation sensor array, including:

[0052] At least one dynamic load cell group 2, each dynamic load cell group 2 includes at least two dynamic load cells, and there are joints between adjacent dynamic load cells in the same group;

[0053] At least one compensation sensor 3 , the compensation sensor 3 is arranged in front or behind the dynamic load cell group 2 along the road direction, and corresponds to the joint of the dynamic load cell group 2 .

[0054]Wherein, in any of the following embodiments, the compensation sensor 3 can also be referred to as a position sensor or a wheel axle recognizer, which can not only be used for the compensation of the following content, but also can be used to detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com