Outer clamping head of square pipe tensile property detection equipment

A testing equipment and tensile strength technology, applied in the field of testing, can solve the problems of high cost, high cylinder requirements, increased cost, etc., and achieve the effect of saving testing cost and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

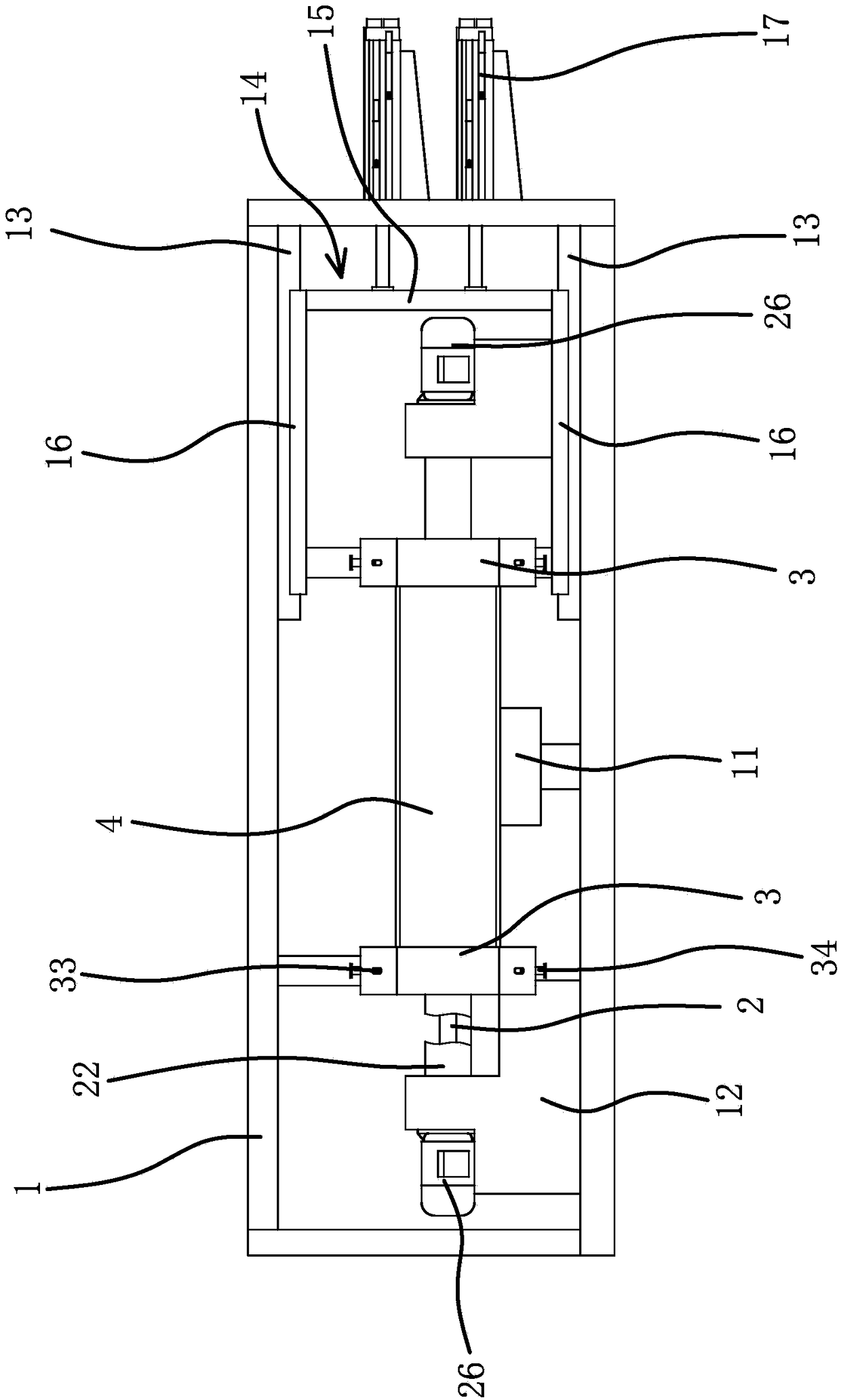

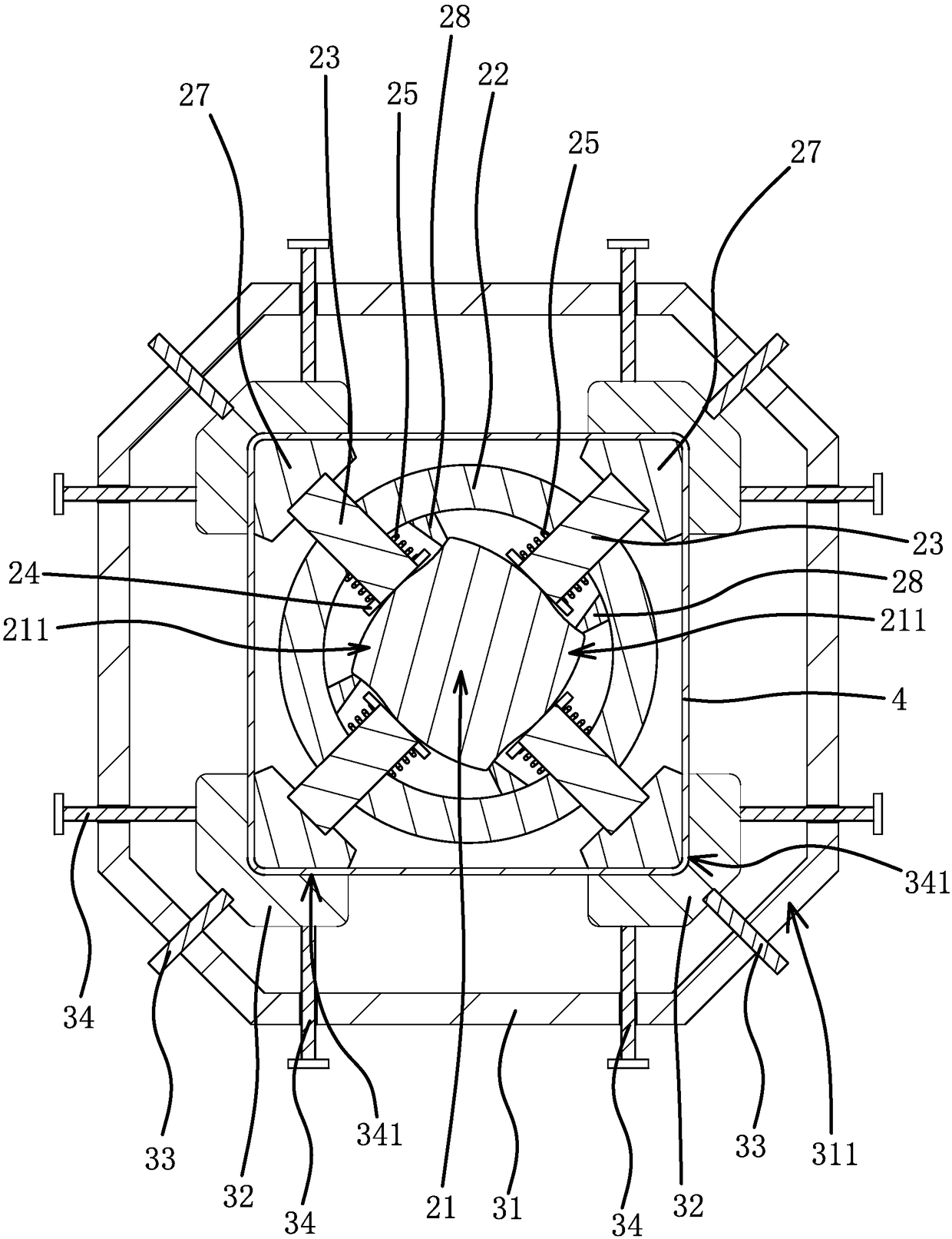

[0016] Such as figure 1 with figure 2 As shown, the square tube tensile testing equipment includes a test box 1 and a pallet 11 fixed in the middle of the test box 1. Clamping assemblies are arranged on both sides of the pallet 11 in the test box 1, and the chuck assembly includes a clamping assembly. The inner mandrel fixed in the square tube 4 and the outer chuck 3 that can be clamped outside the square tube 4, the detection box 1 is fixed with a fixed frame 12 on the side of the pallet 11, and one set of inner cores of the clamping components The shaft and the outer chuck 3 are all fixed on the fixed frame 12, and the detection box 1 is positioned at the opposite side of the pallet 11 to be provided with a guide rail 13, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap