Powder particle sample feeding device

A sampling device and particle technology, applied in the preparation of test samples, analytical materials, instruments, etc., can solve the problems of repeated operation, easy positioning deviation, difficult sampling control, etc., to achieve simple sampling and prevent bleaching powder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

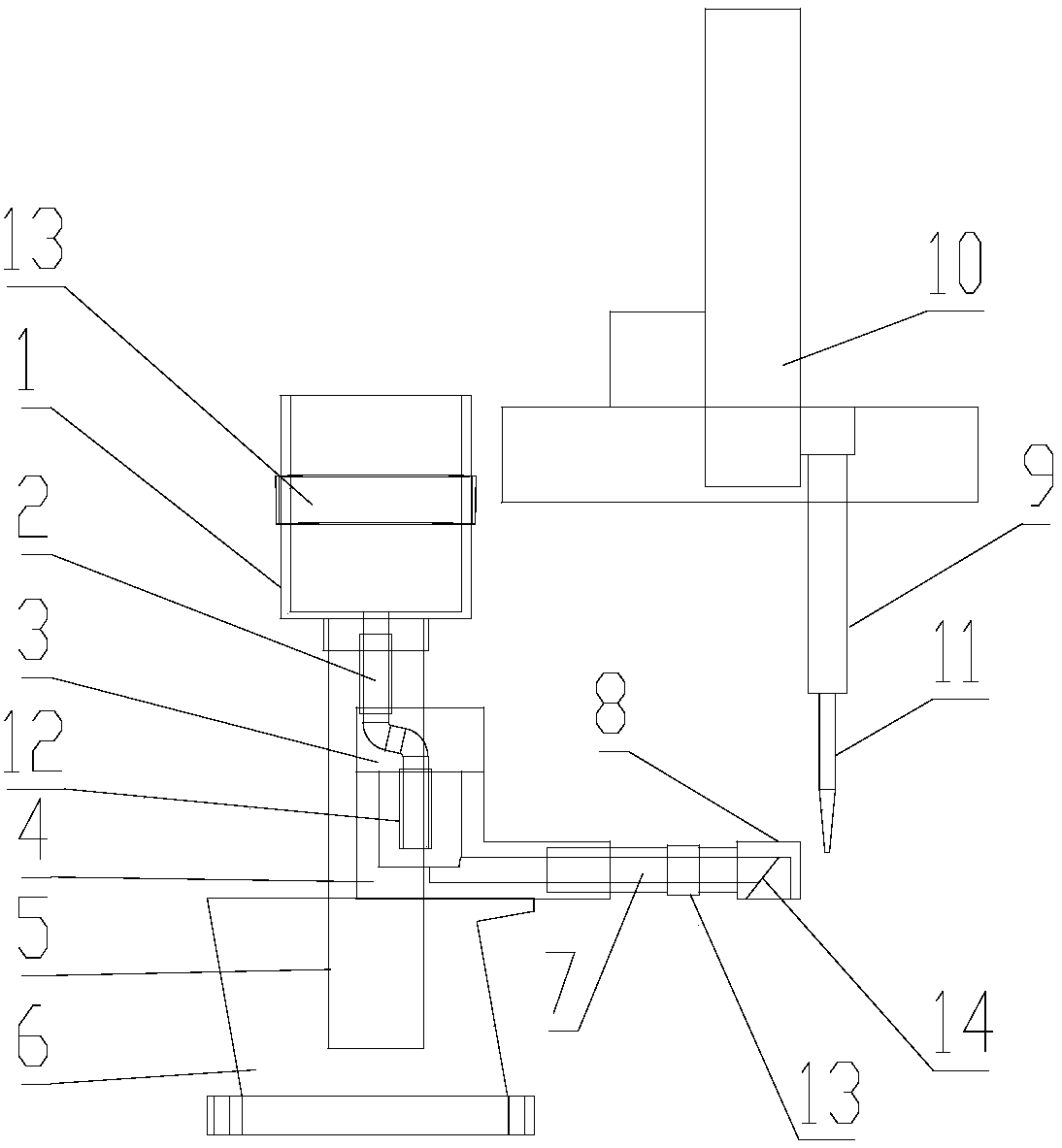

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] A powder particle sampling device includes a feeding component and a powder taking component.

[0022] The feeding assembly includes a material barrel, a powder feeding seat, a bracket, a vibrator, a feeding pipe, a powder outlet, a sealing seat, and a powder dropping pipe. The vibrator is fixed on the platform. The stand is mounted on the vibrator. Two brackets are symmetrically installed on the vibrator. The bucket is installed above the bracket. The powder feeding seat is installed between two brackets. A sealing seat is installed on the upper end of the powder feeding seat, and the sealing seat is connected with the material barrel through the powder dropping pipe. There is a curved powder passage in the sealing seat, and the powder falling pipe is connected with the powder passage; the curved powder passage can reduce the powder flow speed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com