Method for online measuring linearity of raceway of ball linear guide pair

A linear guide pair and measurement method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of high quality requirements for testers and poor accuracy of measurement results, and achieve the effect of accurate, fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

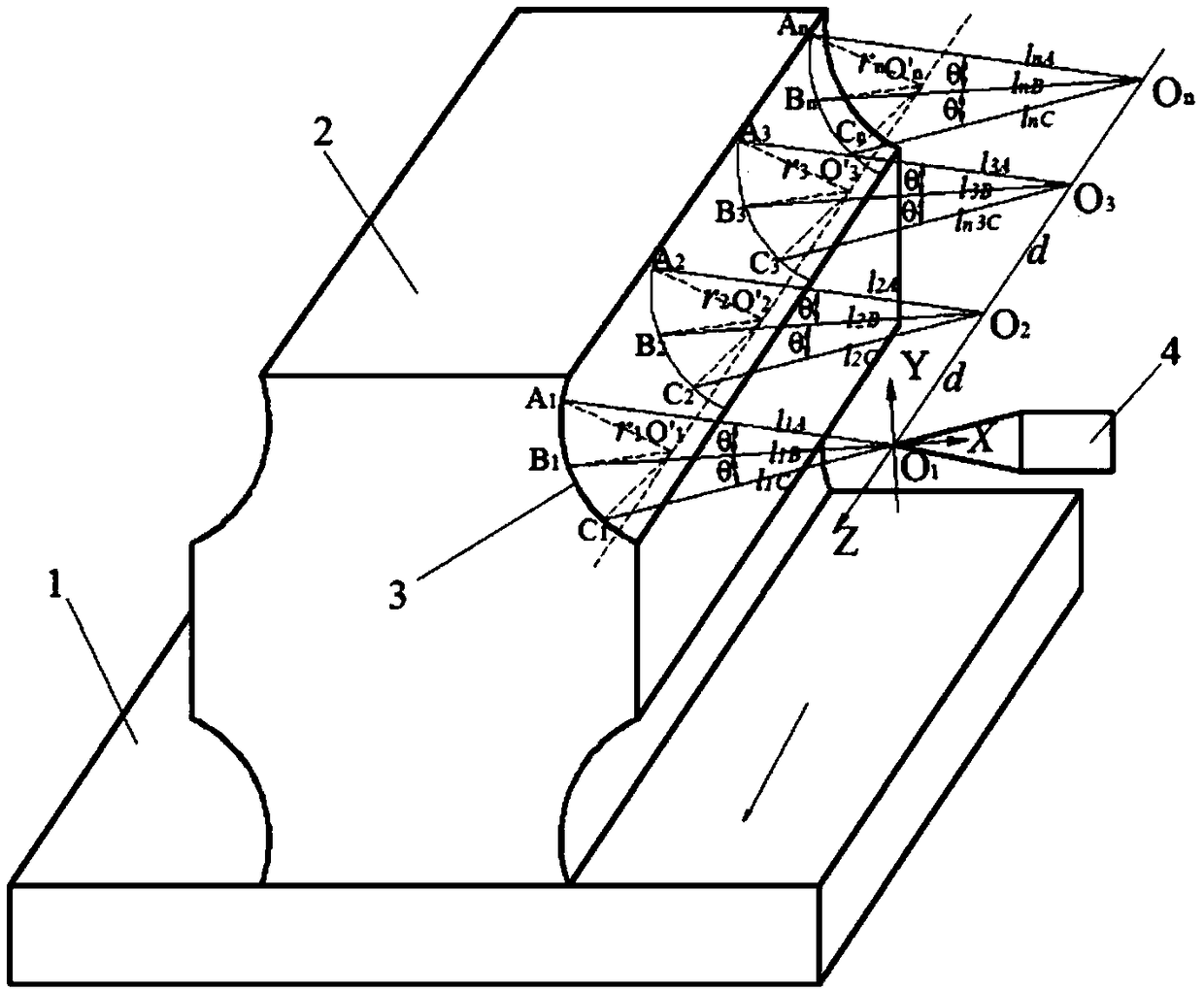

[0037] Such as figure 1 As shown, the present invention provides an online method for measuring the straightness of the secondary raceway of a ball linear guide rail. The online measurement method includes the following steps:

[0038] 1) The laser displacement sensor 4 is installed on the bed of the CNC machine tool through a fixture, and the initial measurement position of the laser displacement sensor 4 is selected as point O 1 , where the fixture drives the measuring head of the laser displacement sensor 4 around the point O in a plane perpendicular to the axis of the raceway 1 Rotate at any angle;

[0039] 2) When grinding the raceway 3 of the linear guide 2, install the linear guide 2 on the workbench 1 of the CNC machine tool through magnetic adsorption, use the forming grinding wheel to grind the raceway 3, and wipe the raceway 3 with alcohol after grinding clean;

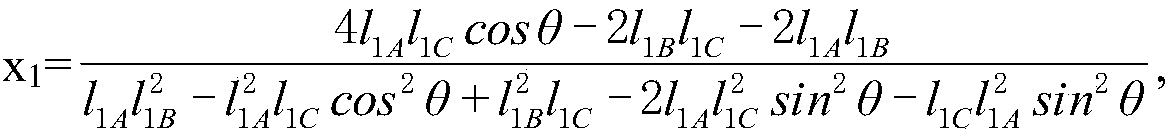

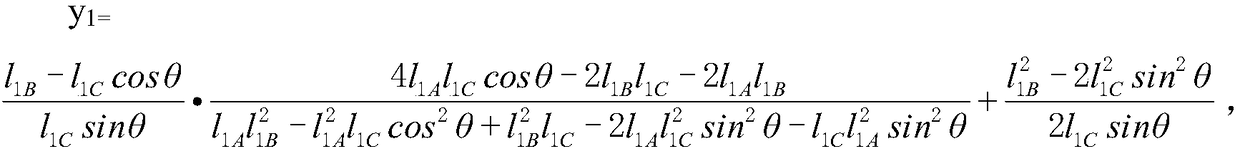

[0040] 3) Using the laser displacement sensor 4 and cooperating with the movement of the CNC machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com