Equipment for packaging pressure frames

A technology of packaging equipment and pressure, applied in the direction of battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of poor placement of separators and polar plates, troubles, left and right plate orientation Inward tilt and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

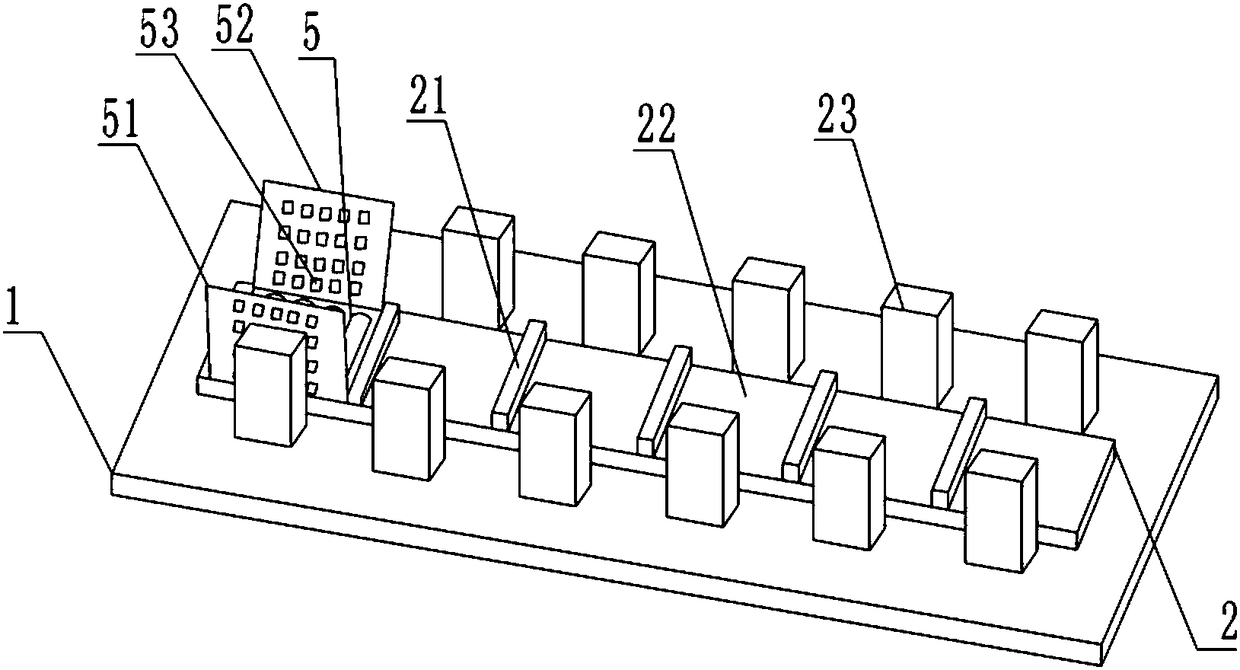

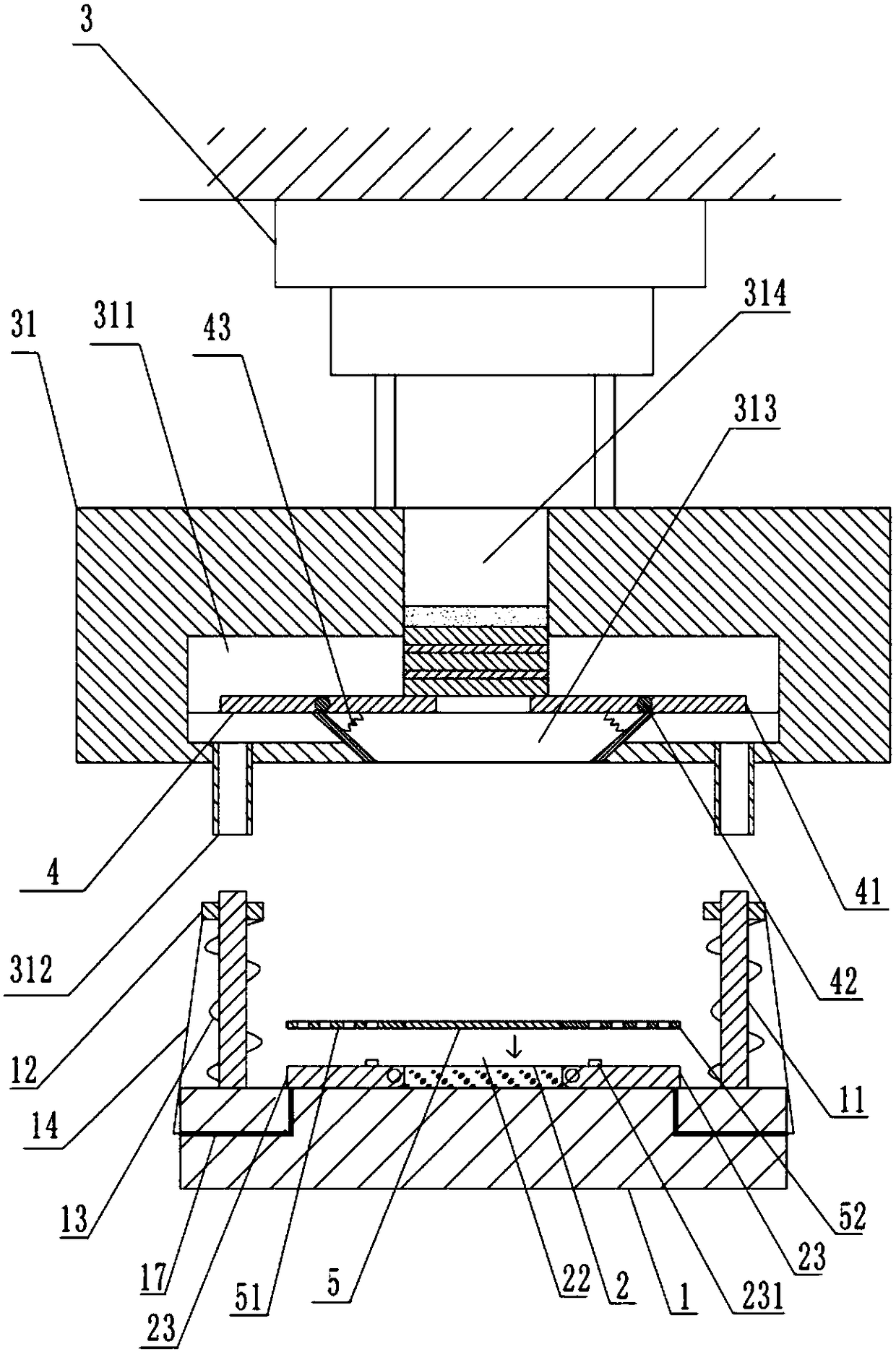

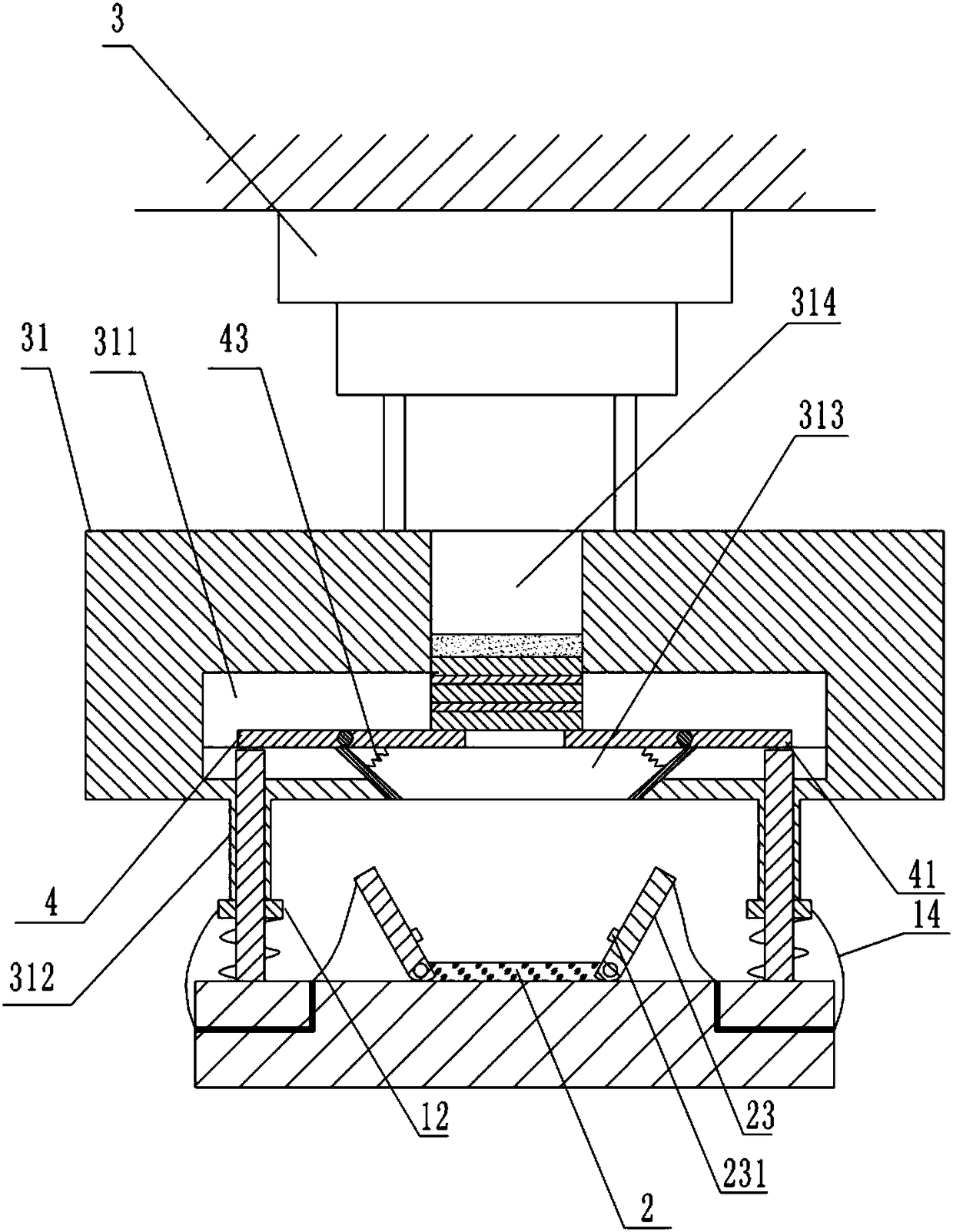

[0033] The reference signs in the drawings of the description include: fixed plate 1, positioning rod 11, limit ring 12, return spring 13, tension line 14, plate body 15, rotating shaft 16, wire hole 17, pressure plate 2, spacer 21 , placement part 22, positioning block 23, positioning protrusion 231, hydraulic cylinder 3, push plate 31, placement cavity 311, limit tube 312, material outlet 313, material inlet 314, first plate 4, second plate 41 , fixed shaft 42, spring 43, base plate 5, left side plate 51, right side plate 52, through hole 53, pressing frame cover 54, pole piece 6, separating plate 61.

[0034] In order to achieve the above object, the basic scheme of the present invention is as follows:

[0035] Such as figure 2 and Figure 6As shown, the pressure frame packaging equipment includes a pressing part, a fixing plate 1 and a pressing plate 2 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com