Test piece grinding machine

A technology of grinding machine and test piece, which is applied in the directions of grinding machine parts, grinding machine, grinding feed movement, etc., can solve problems such as hidden safety hazards, inability to achieve dust-proof work, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

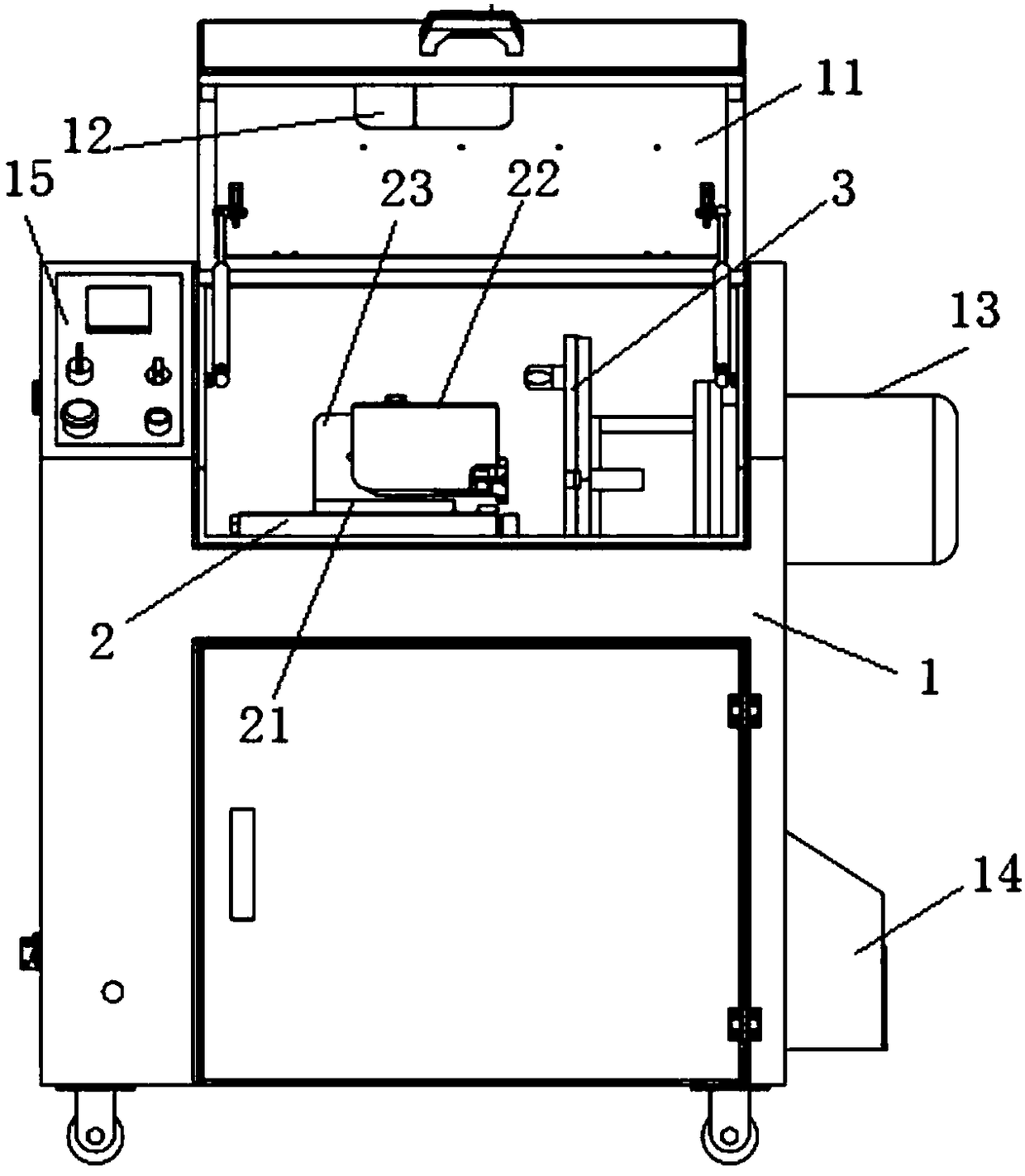

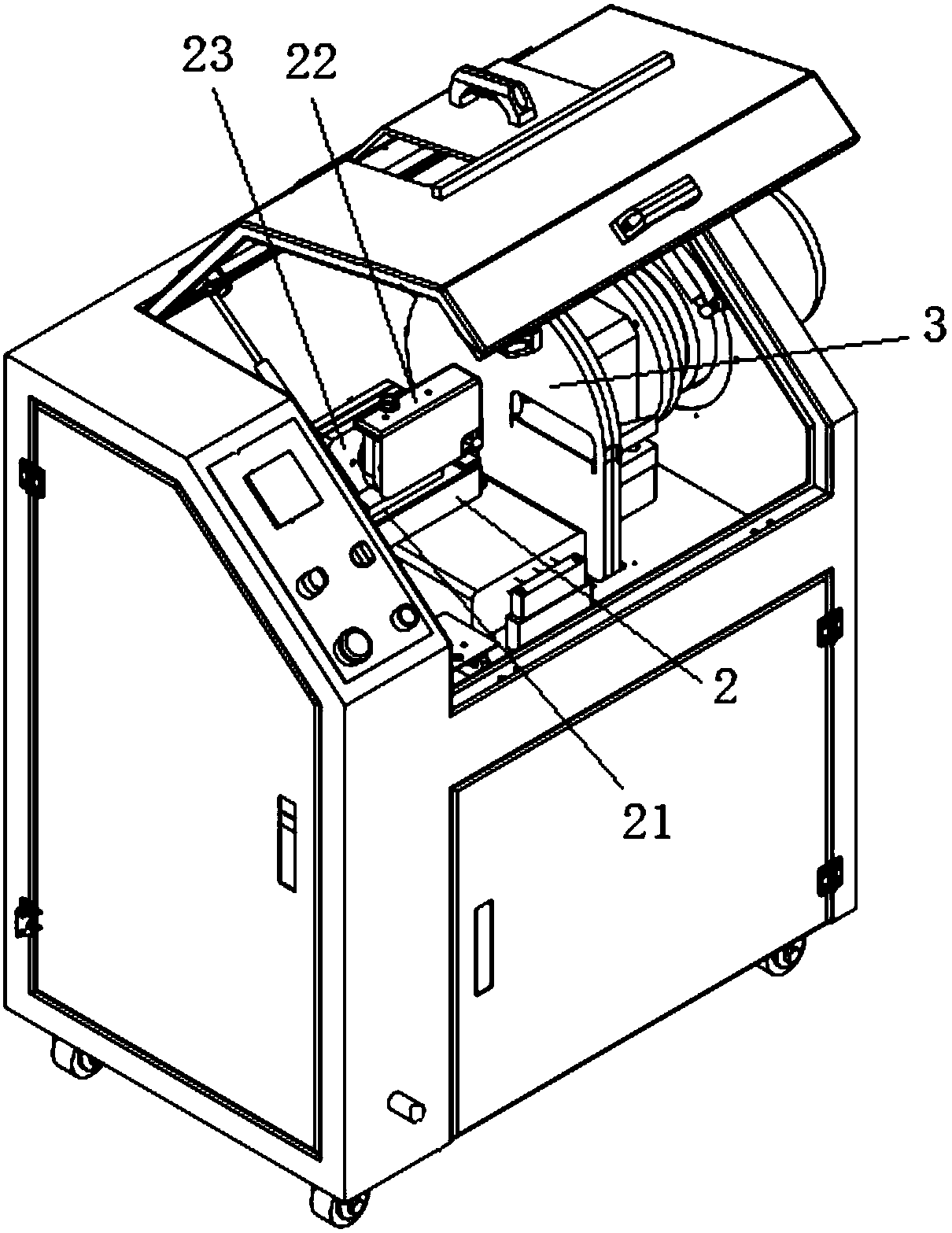

[0018] refer to Figure 1-2 As shown, the present embodiment is a test piece grinder, including a working box 1 and a grinding assembly located in the working box 1;

[0019] The top of the working box 1 is provided with a lifting safety door 11; the top of the safety door 11 is provided with a refueling bin door 12;

[0020] The side of the working box body 1 is provided with a driving device 13 connected to the grinding assembly;

[0021] The outer bottom of the working box 1 is provided with a powder collecting box 14, and the powder collecting box 14 is connected to the working box 1;

[0022] A control panel 15 is arranged outside the working box body 1, and the control panel 15 is connected to control the operation of the grinding assembly;

[0023] The grinding assembly includes a base plate 2, a slide rail 21 arranged on the base plate 2, a jaw 22 arranged on the slide rail 21 and sliding along it; In the same direction;

[0024] The outer side of the jaw 22 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com