Brake abrasion monitoring system

A technology for monitoring systems and brakes, applied in the direction of brake types, mechanical equipment, etc., to solve problems such as brake wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

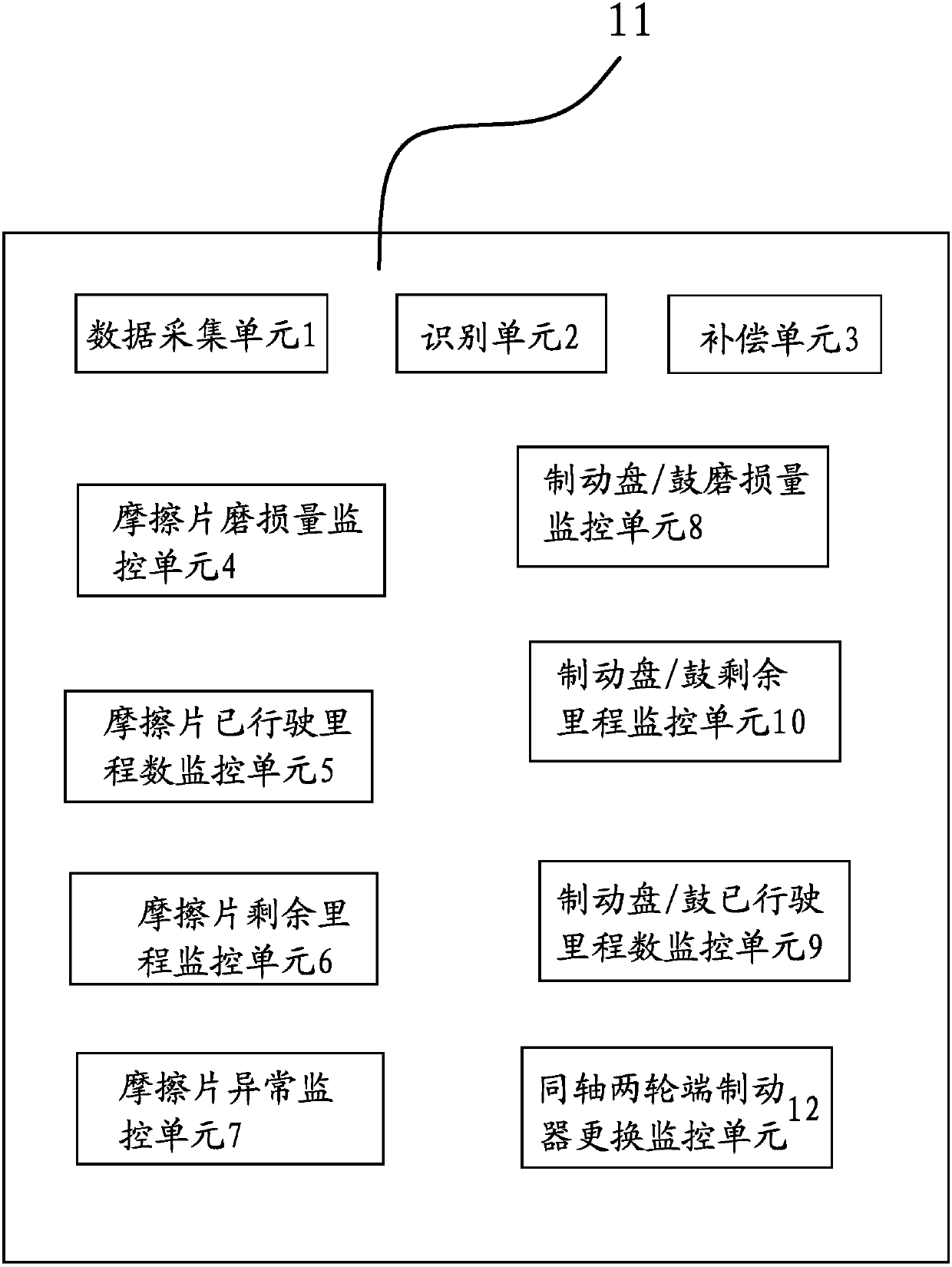

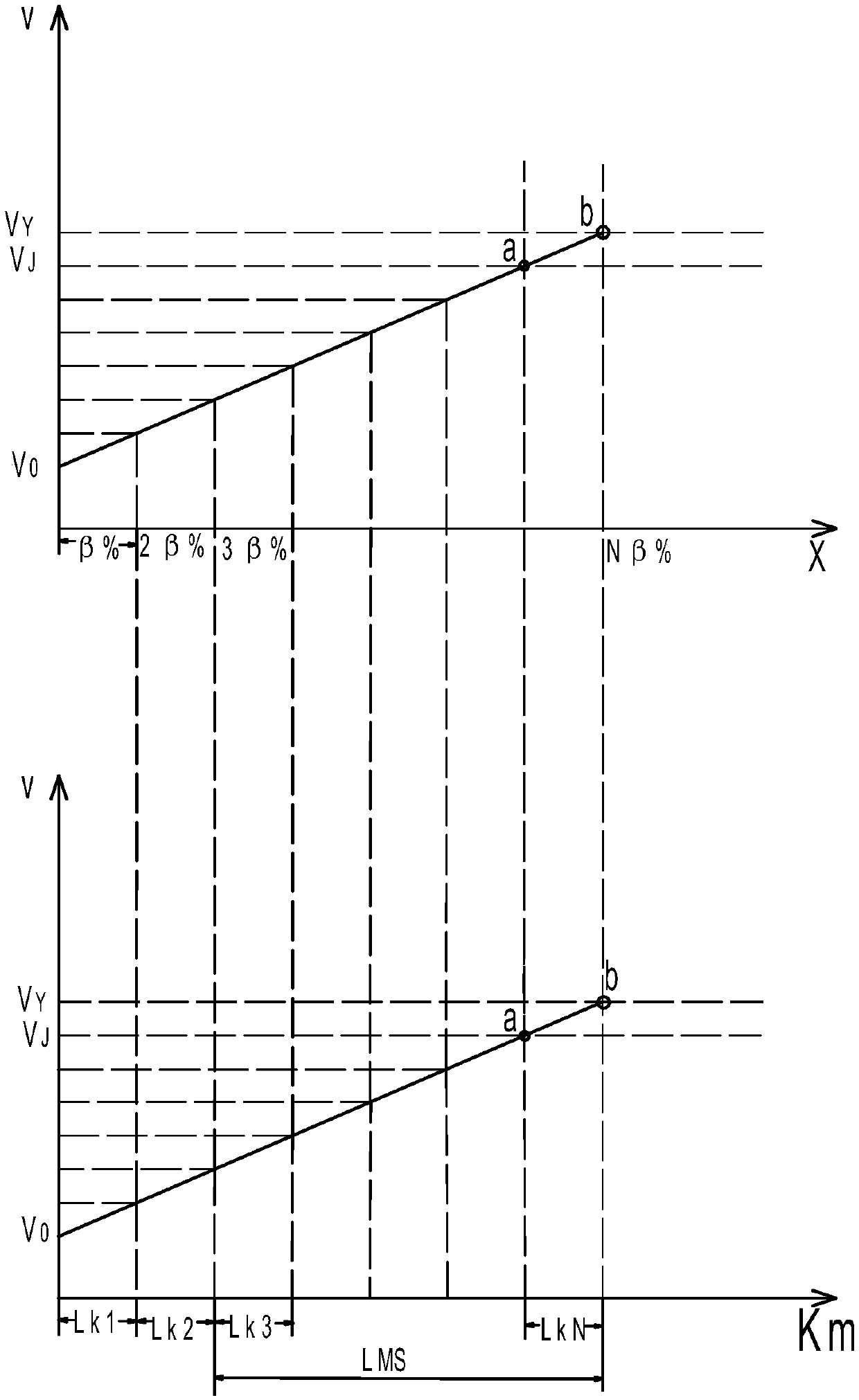

[0039] like Figure 1-2 As shown: the brake wear monitoring system is the control system in the processor 11. The system includes a data acquisition unit 1 for receiving and saving the detection signal reflecting the real-time wear thickness of the friction plate. The system also includes: an identification unit 2 for According to the wear thickness detection signal received in real time, the detection signal variable is formed by comparing the initial detection signal, and the replacement situation of the friction lining and the brake disc / brake drum is judged by the detection variable signal; the compensation unit 3 uses the difference of the original initial detection signal as The initial detection signal of the current fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com