Colorimeter correction method, device and system

A technology of colorimeter and three primary colors, which is applied in the field of devices and systems, and colorimeter correction methods, can solve problems such as high cost, complicated operation, and low efficiency, and achieve the effect of improving factory efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

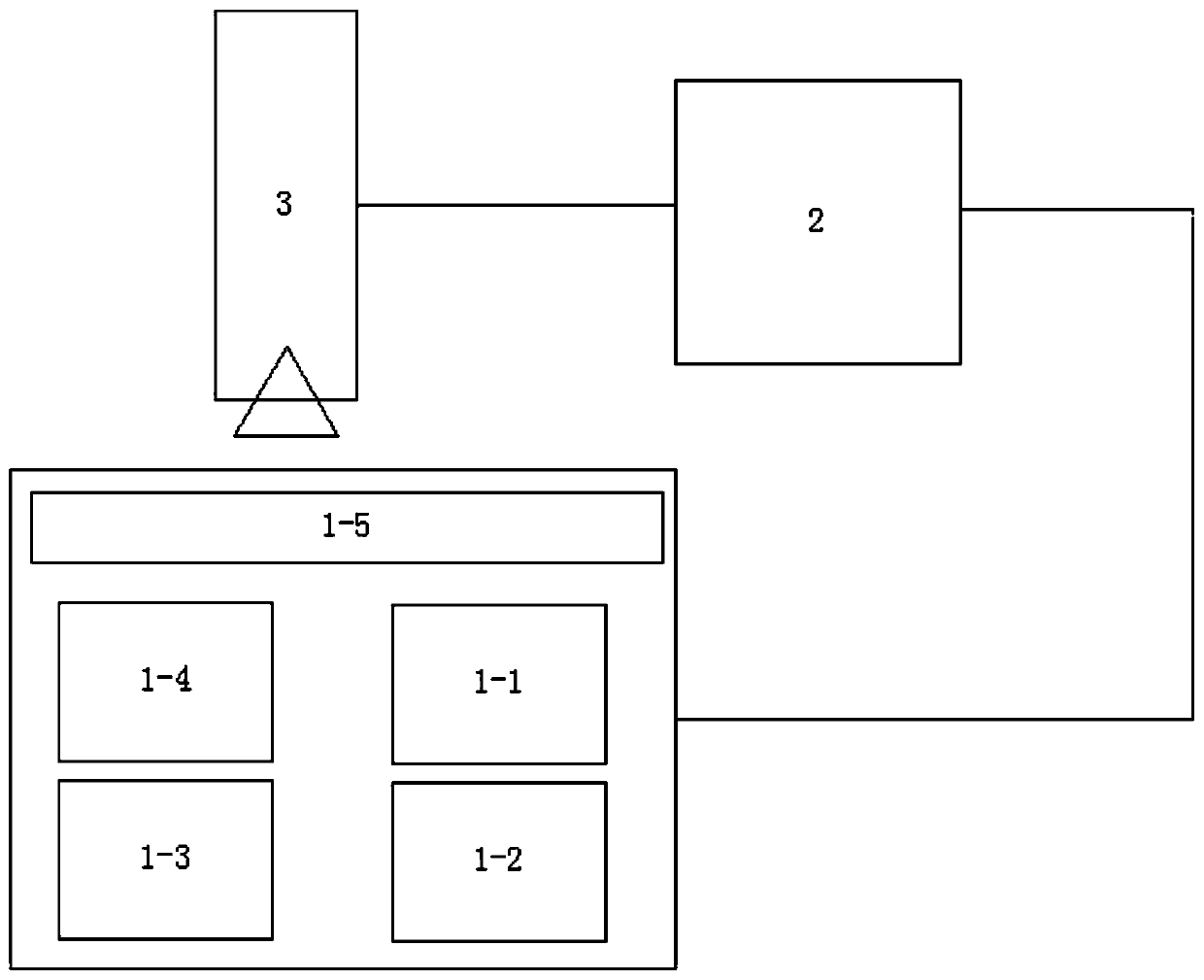

[0028] The present invention proposes a colorimeter correction device 1, including communication interface 1-1, MCU 1-2, constant current source array 1-3, LED array drive 1-4 and LED light source 1-5: used for communication interface 1-1 To communicate with PC2 and receive spectral parameters; MCU1-2 is used to control each current output in constant current source array 1-3; constant current source array 1-3 is used to drive LED array 1-4 according to the control of MCU1-2 Each of the channels outputs current respectively; the LED array driver 1-4 is used to drive the LED light source 1-5 to emit light according to the current output by the constant current source array 1-3; the LED light source 1-5 is used to emit light beams. The constant current source array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com