Row tube correction clamp and method thereof

A tube and tube technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of low work efficiency, cumbersome operation, poor nozzle correction effect, etc., to improve work efficiency, simplify construction procedures, improve The effect of corrective quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

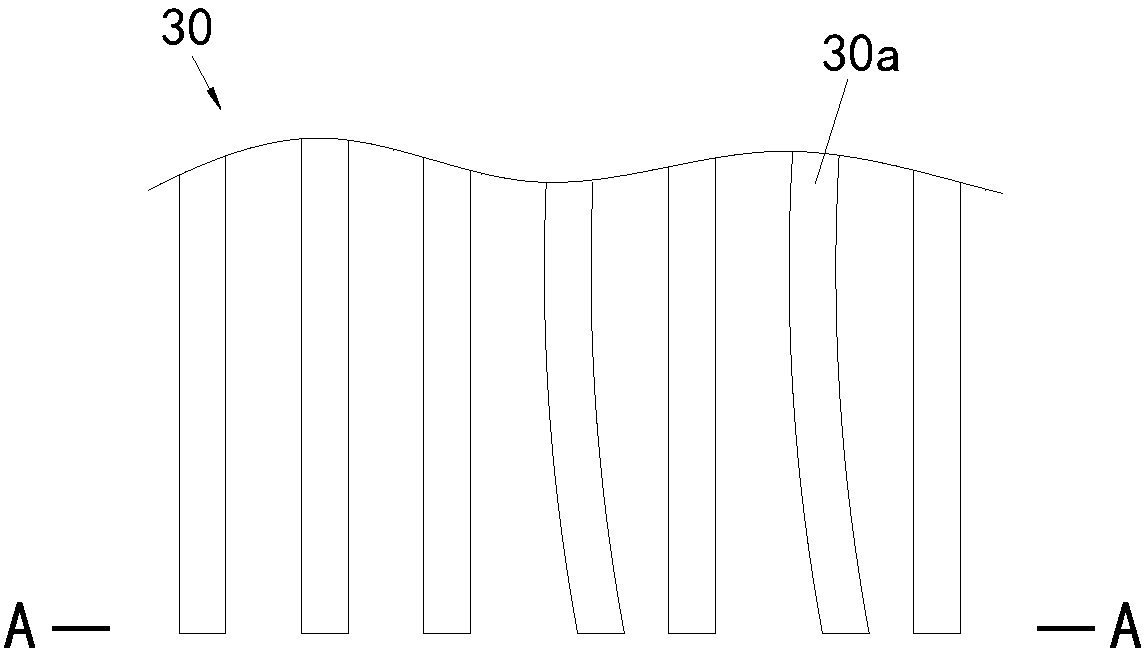

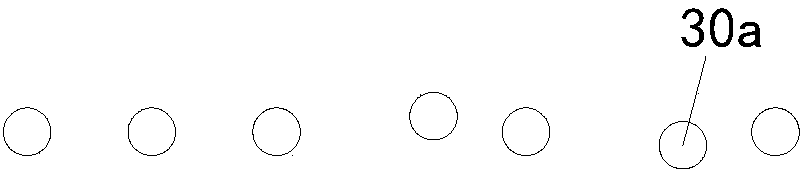

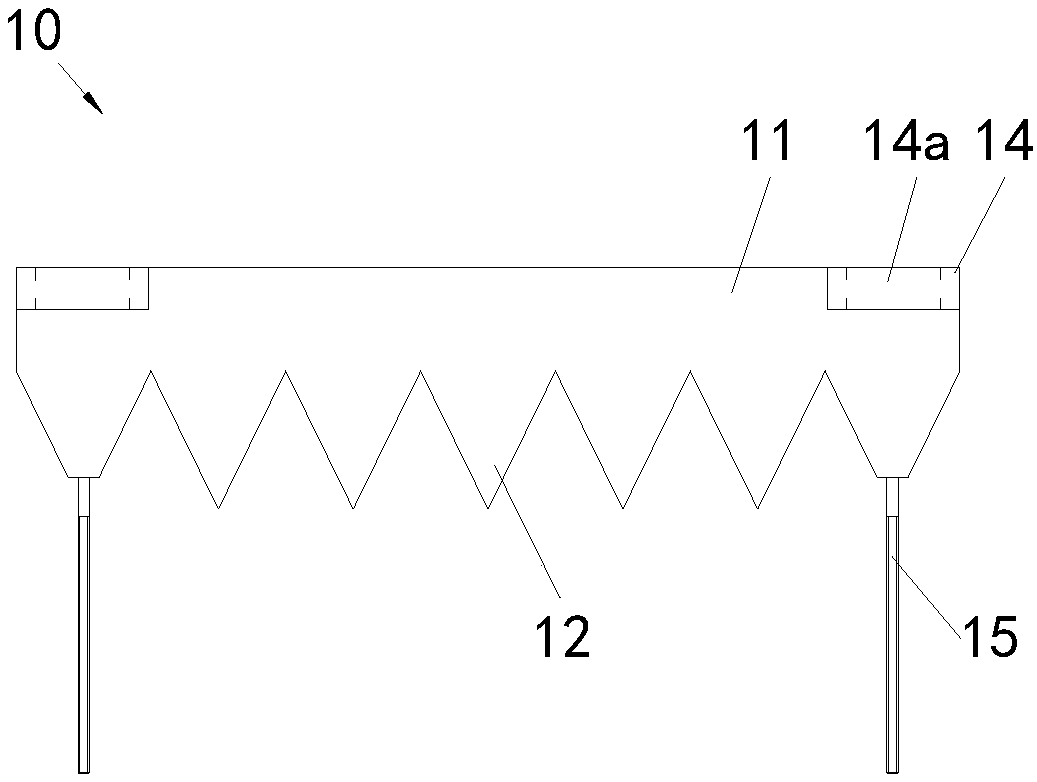

[0030] Example 1: Combining Figure 3 to Figure 9 To illustrate the tube straightening jig of the present invention, in order to clarify the direction relationship, an xyz rectangular coordinate system with the z-axis direction as the height extension direction of the tube straightening jig is set as required. It includes two staggered and oppositely arranged modules, namely the first module 10 and the second module 20; as image 3 and Figure 4 As shown, taking the first module 10 as an example to describe its specific structure in detail, it includes a strip-shaped base 11, the shape and size of which are arranged along the length direction of the base 11 are the same, and a number of sawtooth 12 arranged in a straight line , two screw rods-15 fixedly connected to the bottom of base-11 sawtooth-12 ends, and two positioning blocks-14 with through-holes-14a respectively fixed on the two ends of the side of base-11; Figure 5 As shown, the structure of the second module 20 is...

Embodiment 2

[0034] Embodiment 2: Combination Figure 3 to Figure 11 Illustrate the method for correcting planar tubes with the tube tube correction jig of the present invention, the specific steps are as follows:

[0035] S1: if Figure 5 to Figure 7 As shown, assemble the jig for straightening tubes described in Embodiment 1, assemble the first module 10 and the second module 20 arranged up and down, and the saw teeth of the two modules are horizontally staggered and vertically opposite, the first module 10 The screw rod one 15 passes through the through hole two 24a of the positioning block two 24 of the second module 20 and is locked and fixed by a nut; The nuts are locked and fixed, and the screw rods respectively penetrate into the through holes of the opposite base and are tightened by the nuts. By tightening and loosening the nuts, the gap between the sawtooth of the two modules can be adjusted to adapt to the tube structure of different pipe diameters and gaps 30;

[0036] S2: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com