Deviation correcting device for preventing cigarette making machine tipping paper from deviating

A deviation correction device, tipping paper technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problem of tipping paper deviating from the correct position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

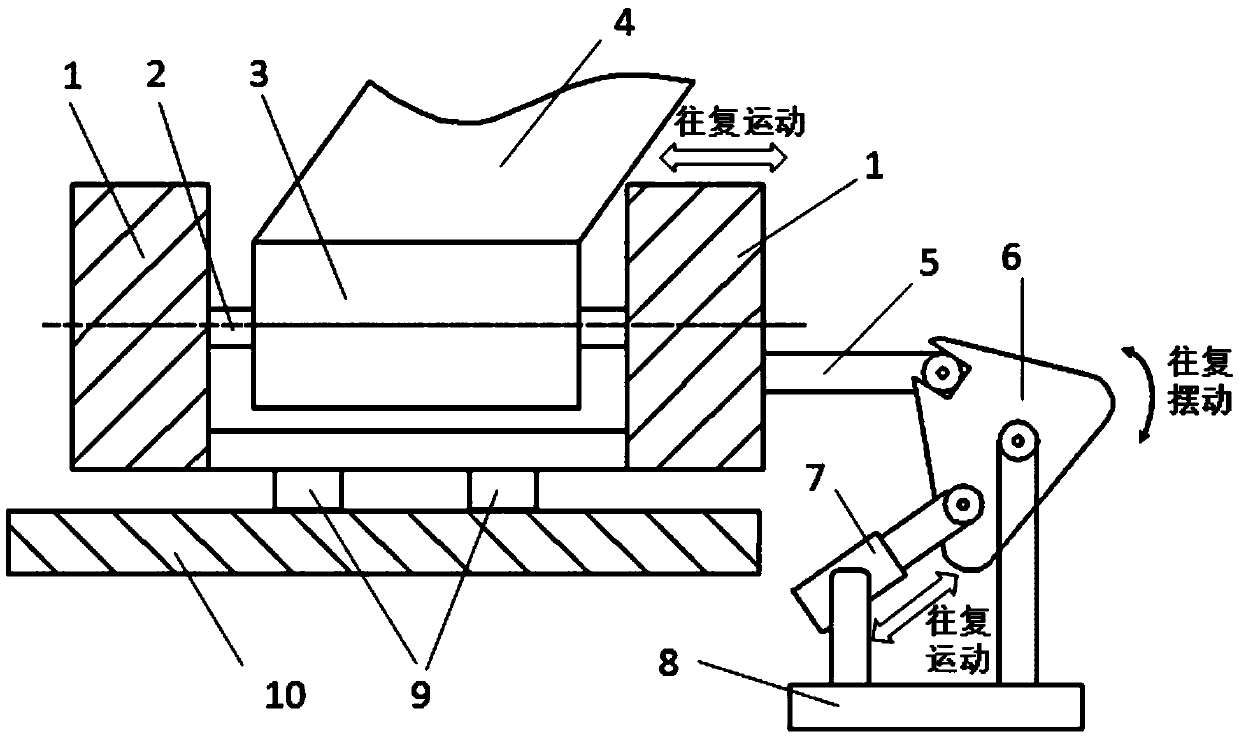

[0013] Example: such as figure 1 As shown, a deviation correcting device for preventing the tipping paper of a cigarette machine from running off, including: a roll support frame 1, a roll shaft 2, a roll 3, a connecting shaft 5, a connecting plate 6, a cylinder 7, a fixed bracket 8, and a slider 9. Linear slide rail 10;

[0014] The reel 3 is located on the roller shaft 2 of the roll support frame 1, the tipping paper 4 is wound on the reel 3, and the roll shaft 2 is located on the central axis of the reel 3 to ensure that the reel 3 is positioned on the roll support frame 1. Carry out small-scale reciprocating swings;

[0015] The roll support frame 1 is located on the slider 9, the number of the sliders 9 is 2, and the slider 9 is located on the linear slide rail 10;

[0016] One end of the connecting shaft 5 is fixedly connected to one side of the roll support frame 1, and a pulley is positioned at the other end of the connecting shaft 5, the pulley of the connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com