Preparation process of screen mesh corset

A preparation process and a technology for shapewear, which are applied in the direction of sewing tools and other directions, can solve the problems of weak flocking firmness, low work efficiency, and inability to improve the overall elasticity of the shapewear, so as to improve the scratching effect and high work efficiency. , the effect of strong firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

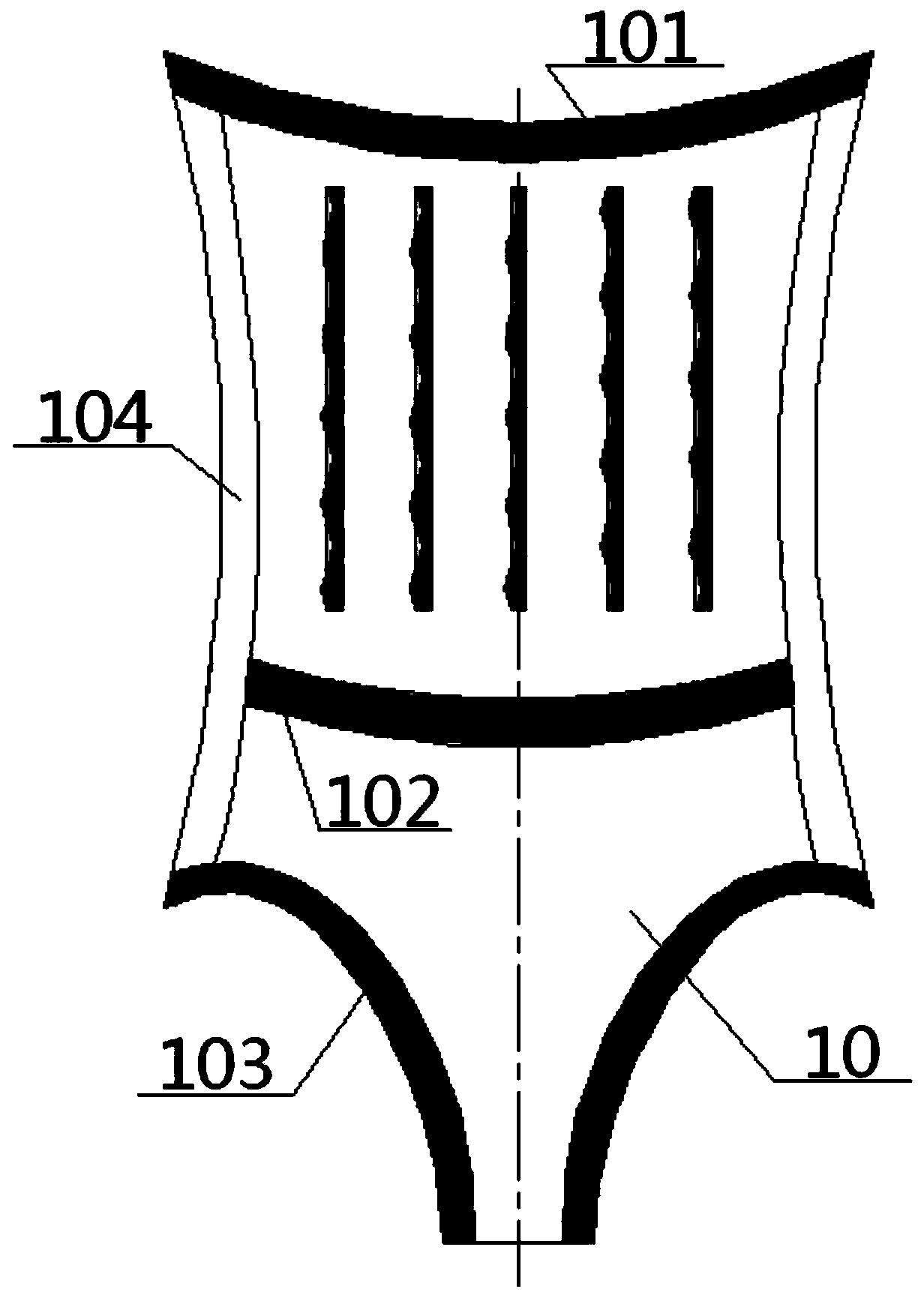

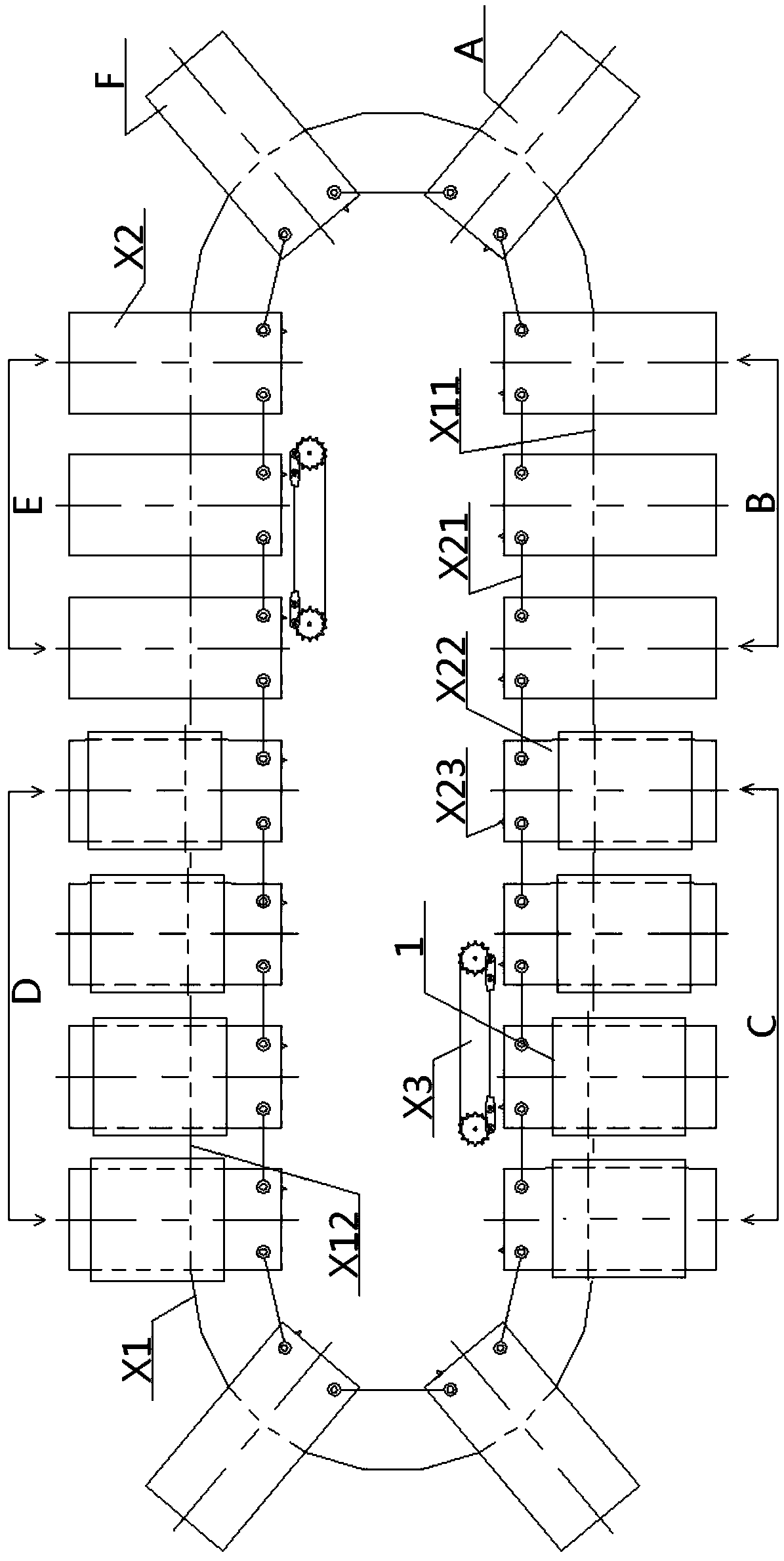

[0064] see Figure 1 to Figure 15 , a preparation process of a screen body shaper, comprising a cutting step and a stitching step carried out in sequence, the cutting step refers to cutting the front panel 10 and the back sheet required to form the wire mesh body shaper, and the stitching step refers to the The front piece 10 and the back piece are sewed together to obtain the silk net body shaping garment; the front piece first processing step is also included between the cutting step and the sewing step, and the front piece first treatment step includes the following operations in turn: first activate the transmission track X1 and The platen driving device X3, the transmission track X1 is a closed ring structure, and the top of the transmission track X1 is sequentially provided with a laying station A, a printing release agent station B, and a rubber printing station C. , rubber printing lower station D, flocking station E, cloth receiving station F, the printing release age...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

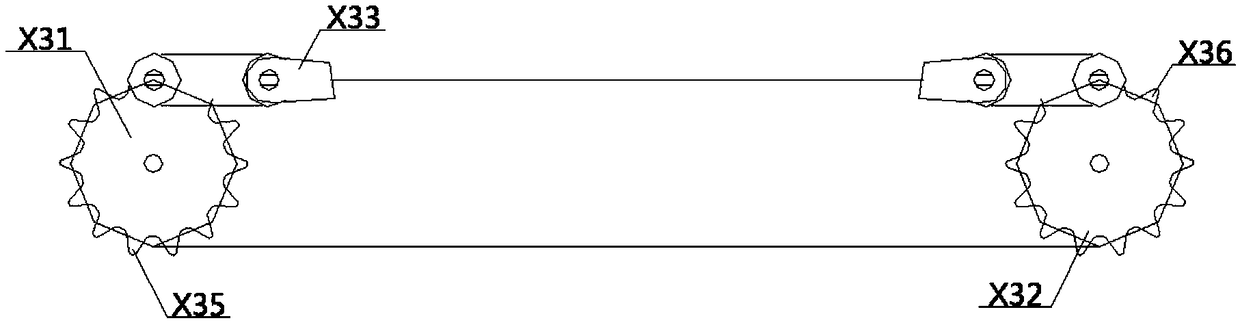

[0067] The platen driving device X3 includes an upper left sprocket X31, an upper right sprocket X32 and an upper chain X33, the upper left sprocket X31 and the upper right sprocket X32 are smooth toothless sprockets, and the upper chain X33 The left and right ends of the chain are respectively wound around the outer periphery of the upper left sprocket X31 and the upper right sprocket X32; the upper chain X33 is a ring structure, including a plurality of upper chain shaft groups X34 with the same structure, and the adjacent upper chain shaft groups The top and bottom ends of X34 are respectively connected by upper and lower group plates X342 and upper and lower group plates X343. There is an upper group gap X344 between adjacent winding shaft groups X34. One winding shaft X341 includes two parallel winding shafts. shaft X341, the upper chain shaft X341 is a vertical column structure, there is an upper shaf...

Embodiment 3

[0070] Basic content is the same as embodiment 1, the difference is:

[0071] A screen frame 1 is arranged directly above the platen X2 in the upper printing station C and the lower printing station D, and a scraper 2 connected to the scraper seat plate 4 is arranged directly above the screen frame 1 , second scraper 3, the left side of described screen frame 1 is connected with the bottom of left vertical board 71, and the top of left vertical board 71 is vertically connected with the inner side of left horizontal board 72, and the top surface of left horizontal board 72 is connected with The bottom of the left vertical adjustment device 7 of the screen frame is connected, the right side of the screen frame 1 is superimposed and connected with the top surface of the lower right horizontal plate 81, and the right side of the lower right horizontal plate 81 is connected with the bottom of the right vertical plate 82 Vertically connected, the top of the right vertical plate 82 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com