A kind of building wiring pipeline corrector

A straightener and pipeline technology, applied in the field of construction, can solve problems such as broken pipelines and poor bending effects, and achieve the effects of preventing pipelines from bending and cracking, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

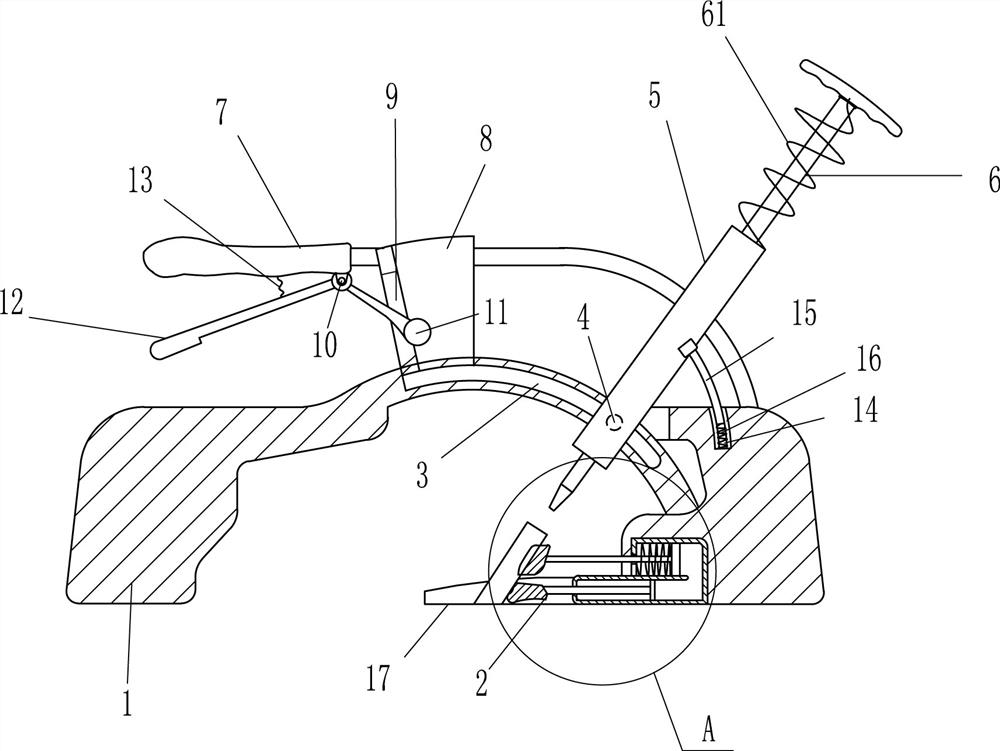

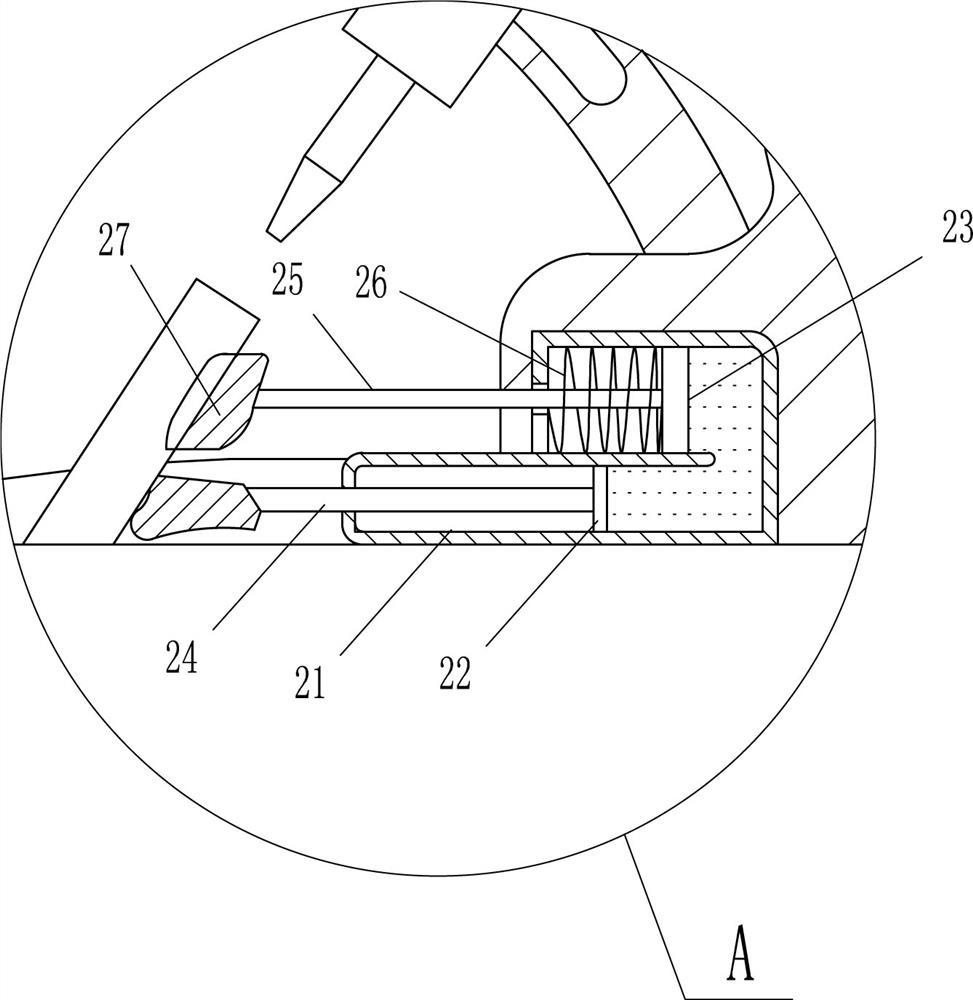

[0017] The ejector 2 includes an N-shaped cylinder 21, a first piston 22, a second piston 23, a first push rod 24, a second push rod 25,

Embodiment 2

[0020] As shown in Figure 1, on the basis of Embodiment 1, it also includes an N-shaped block 8, a mounting seat 10, a swing rod 11, and a grip rod 12.

[0022] Also includes an arc-shaped sleeve 14, a buffer block 15 and a fourth elastic member 16, which are embedded near the top of the fixing frame 1 of the ejector 2.

[0023] Also includes a guide plate 17, the two guide plates 17 are symmetrically arranged on the fixed frame 1 with the ejector 2 as the central axis. when

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com