Centrifugal clutch

A centrifugal clutch and clutch technology, applied in clutches, automatic clutches, mechanical equipment, etc., can solve the problems of difficult operation by operators, long time, low fuel efficiency, etc., and achieve the effect of simplifying the structure and suppressing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

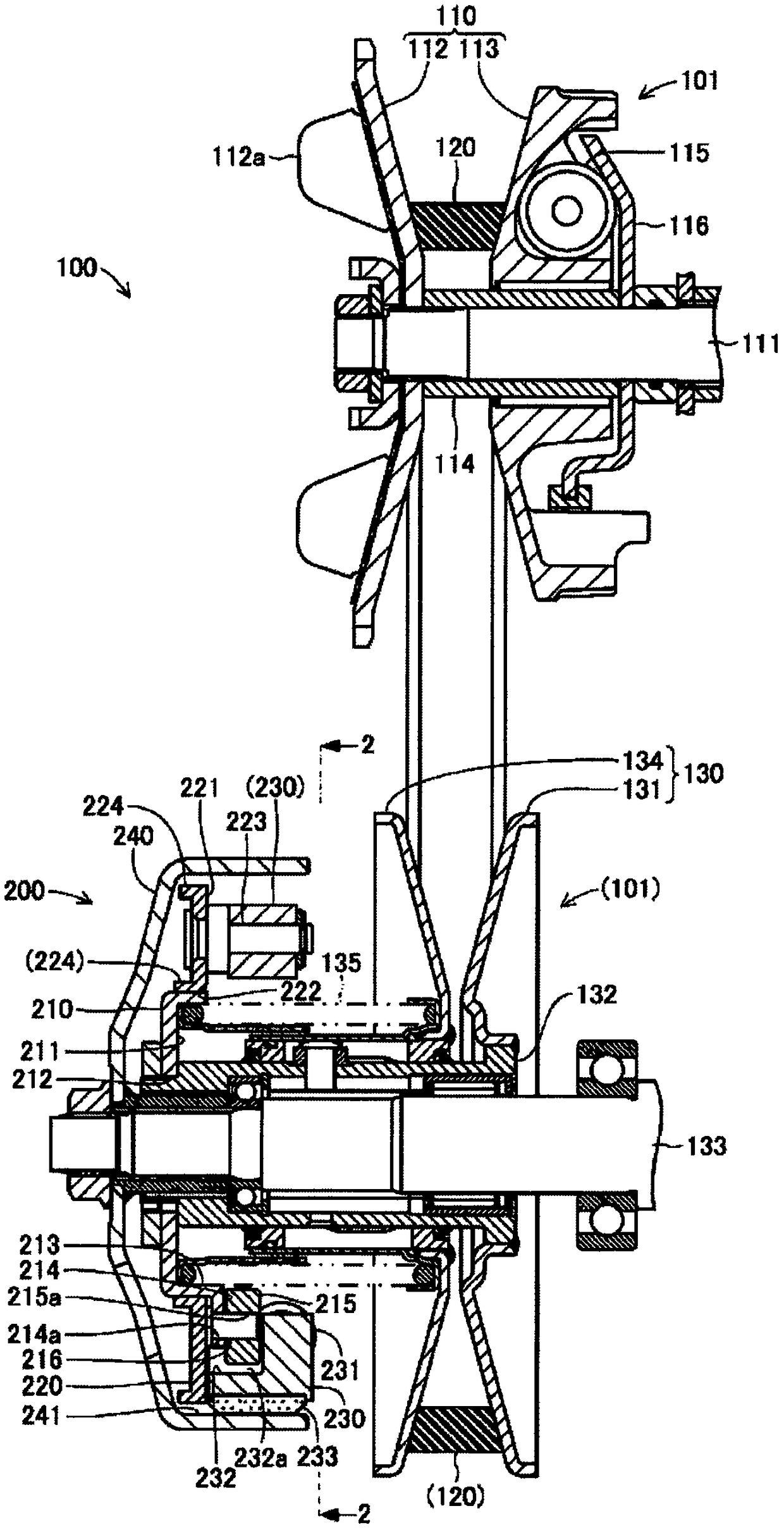

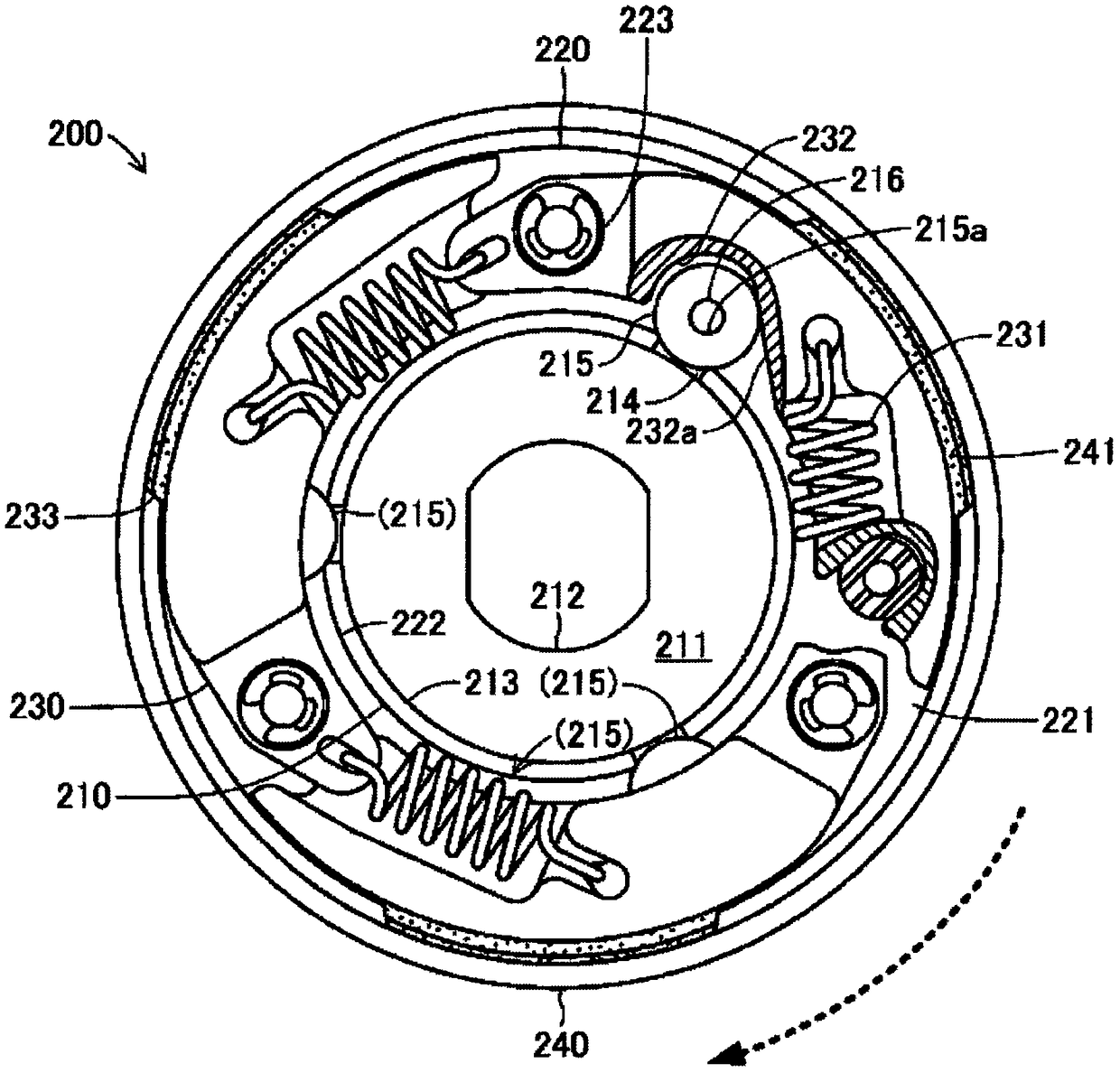

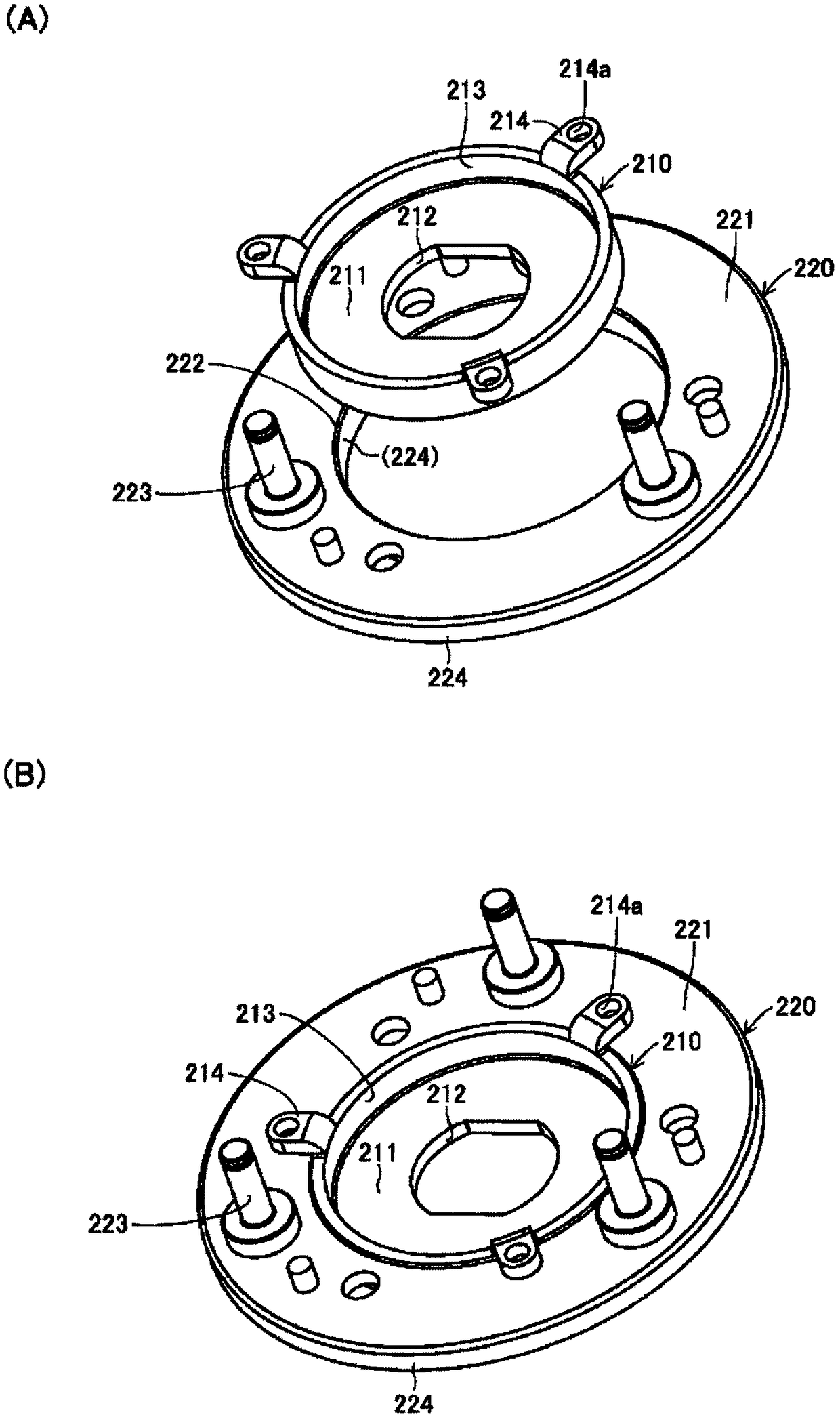

[0035] Hereinafter, one embodiment of the centrifugal clutch according to the present invention will be described with reference to the drawings. figure 1 It is a top sectional view schematically showing the structure of the power transmission mechanism 100 provided with the centrifugal clutch 200 of the present invention. also, figure 2 for from figure 1 A side view of the centrifugal clutch 200 is shown on the 2-2 line. The power transmission mechanism 100 equipped with the centrifugal clutch 200 is mainly installed between the engine and the rear wheel as the driving wheel in a motorcycle such as a scooter, and rotates the drive while automatically changing the reduction ratio relative to the number of revolutions of the engine. Mechanical device that transmits or disconnects force to the rear wheels.

[0036] (Configuration of Centrifugal Clutch 200)

[0037] The power transmission mechanism 100 mainly includes a transmission 101 and a centrifugal clutch 200 . The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com