Clockwise and counterclockwise rotation switching device for power tool

A technology of electric tools and switching devices, which is applied in the direction of electromechanical devices, portable motorized devices, manufacturing tools, etc., can solve the problems of contact pressure reduction, achieve the effects of improving contact life, avoiding cost increases, suppressing vibration and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

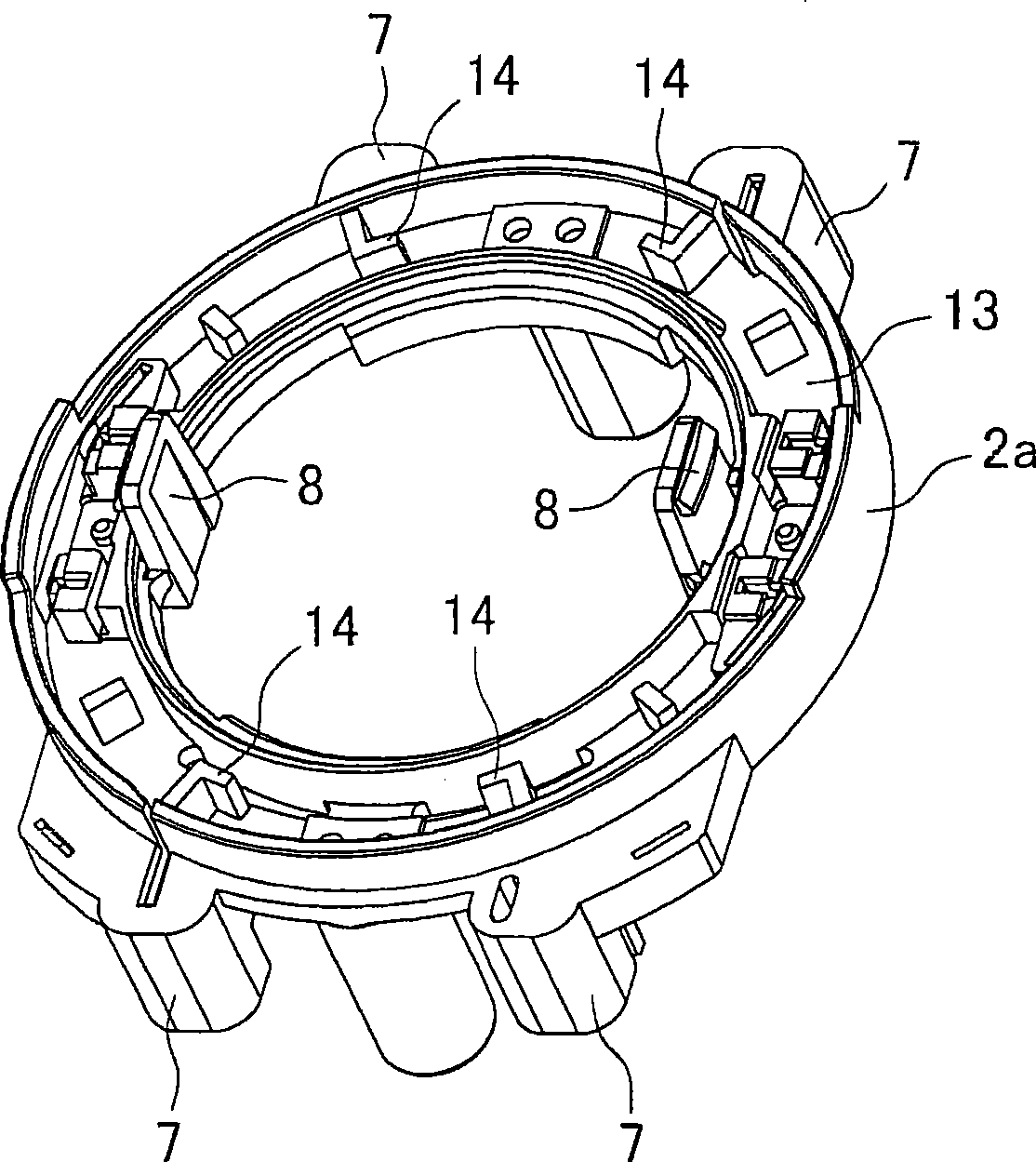

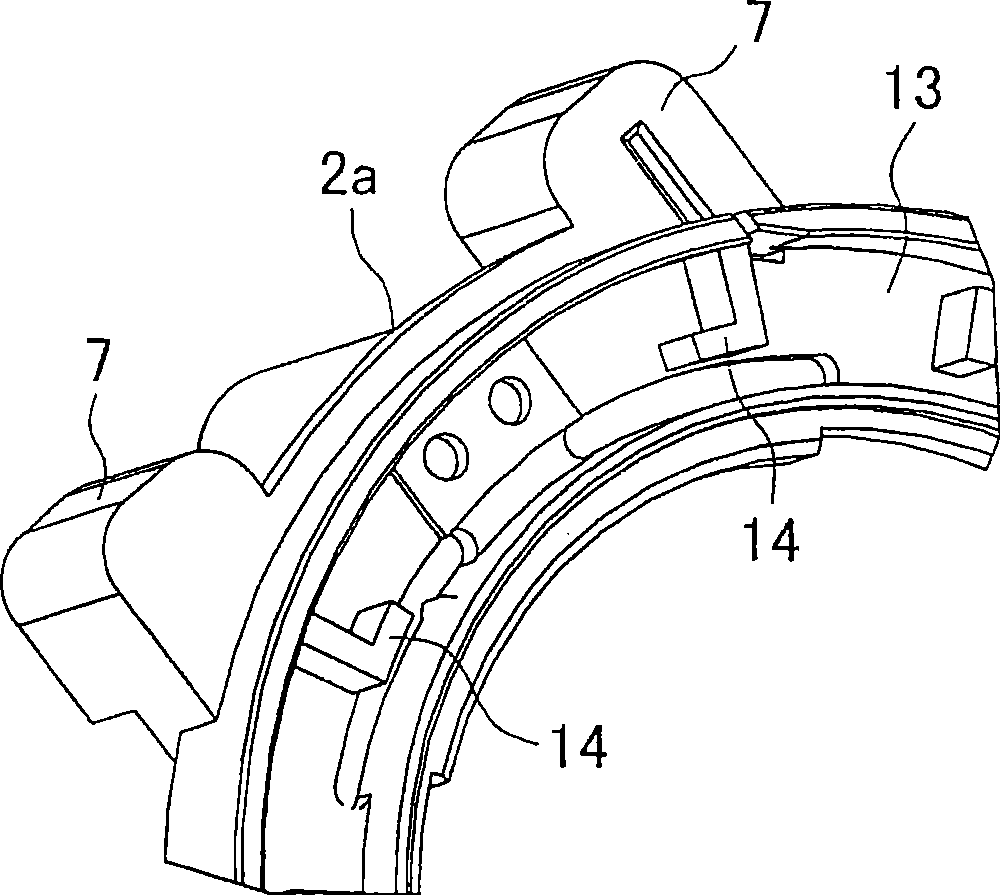

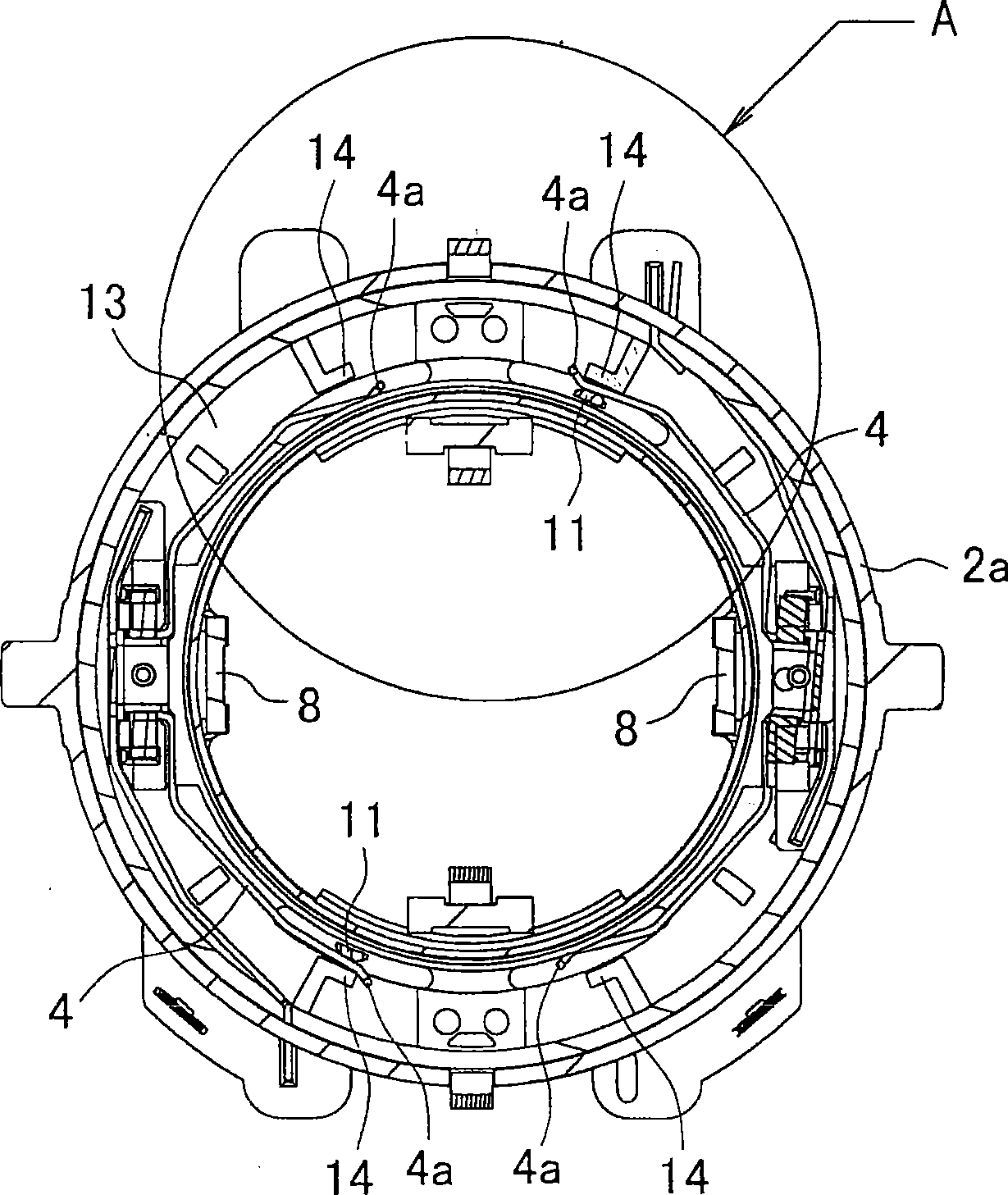

[0024] Figure 1A and Figure 1B It is an explanatory diagram of a component base (a state where a fixed contact is not attached) 2a used in the forward and reverse switching device of the present invention, Figure 1A represents a stereogram, Figure 1B Indicates a partially enlarged view. Figure 2A and Figure 2B is an explanatory diagram of the component base 2a in a state where the fixed contacts are mounted, Figure 2A for top view, Figure 2B An enlarged view of part A. In this component base 2a, there are a pair of fixed contacts 4, 4 in a point-symmetrical planar arc shape, etc. Figure 6 , Figure 7 , Figure 8A and Figure 8B The component base 2 described in is the same, but on the bottom plate 13 of the component base 2a of the present invention, on the outer peripheral side of each elastic end 4a of the fixed contact 4, integrally protrudingly provided with L-shaped as a restricting portion when viewed from above. Limit protrusions 14 . When the movable...

no. 2 approach

[0028] Figure 3A and Figure 3B It is also an explanatory diagram of the component base 2b in the state where the fixed contact is not installed, Figure 3A represents a stereogram, Figure 3BIndicates a partially enlarged view. In the member base 2b, a through hole 15 is provided at the front end of the regulating protrusion 14 on the bottom plate 13, so that the leading end of the regulating protrusion 14 is provided with elasticity.

[0029] Therefore, by the forward and reverse switching device, the brush base 3 is rotated to the forward rotation position, the movable contact 11 is in contact with the elastic end 4a of the fixed contact 4, and the elastic end 4a is flexibly deformed to the outer peripheral side so as to contact the regulating protrusion. 14 abutment, at this time, if Figure 4 As shown, the lower end of the regulating protrusion 14 flexibly deforms toward the outer peripheral side due to its elasticity, and presses the elastic end 4 a toward the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com