Intensive mixing granulator

A technology of mixing granulation and granulation machine, which is applied in the direction of granulation in the rotary tank, can solve the problems of low granulation rate and poor mixing granulation effect, and achieve improved granulation rate, improved mixing effect, and improved The effect of the granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

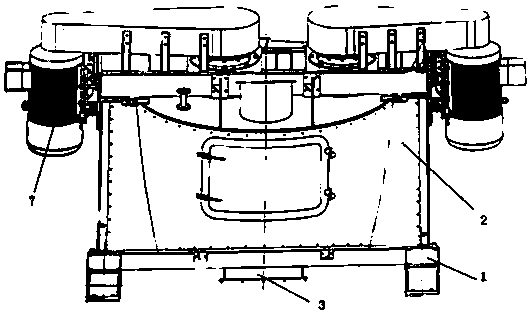

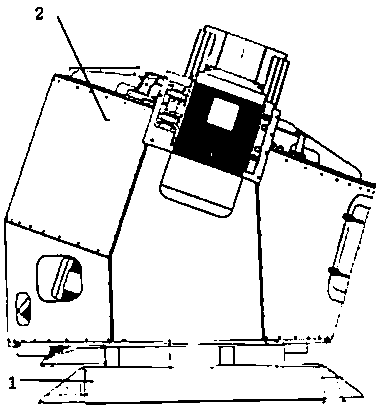

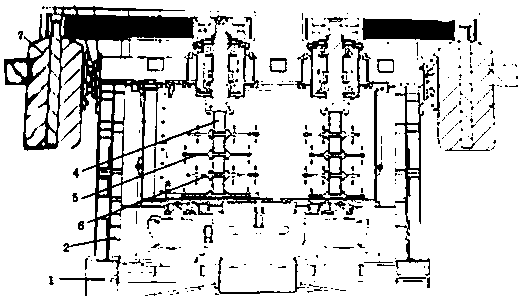

[0014] like Figure 1-Figure 3 As shown, the present invention discloses a powerful mixing and granulating machine, including a base 1, a mixing and granulating cylinder 2 rotatably arranged on the base 1, and a first rotor rotatably arranged in the mixing and granulating cylinder 2 Assemblies and the second rotor assembly, the upper end of the mixing and granulating cylinder 2 is provided with a feed hole, the lower end of the mixing and granulating cylinder is provided with a discharge port 3, the base 1 is horizontally arranged, and the The mixing and granulation cylinder 2 is arranged obliquely relative to the base 1, and there is an included angle between the mixing and granulation cylinder 2 and the base 1, and the angle of the included angle is 1°-20°. In this embodiment Preferably, the inclination angle is 20°. A first drive mechanism ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap