Environment-friendly extruding device

An extrusion device, an environment-friendly technology, applied in the direction of metal extrusion, pressure head/punch rod, metal processing equipment, etc., can solve the problems of difficult movement, cumbersome operation, complex structure, etc., and achieve simple equipment structure, easy cleaning and The effect of high maintenance and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

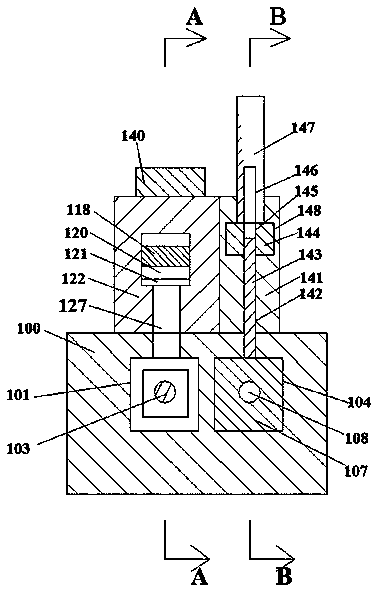

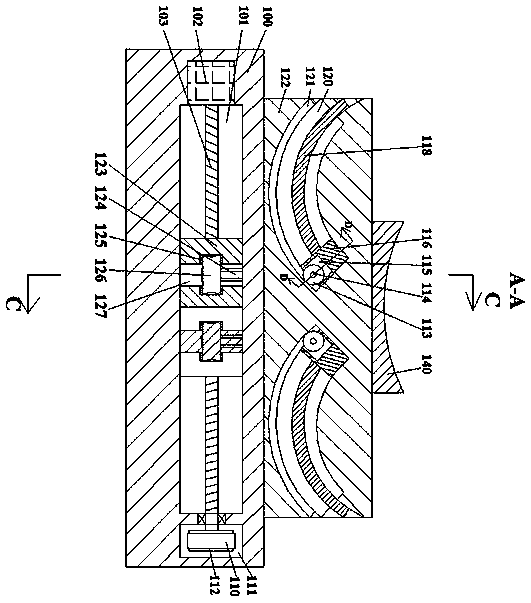

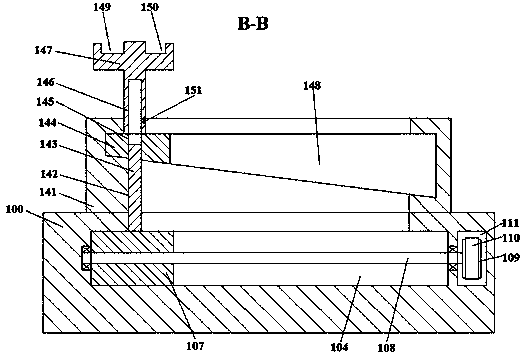

[0018] Such as Figure 1-Figure 5As shown, an environmentally friendly extrusion device of the present invention includes a machine base 100 and an extrusion machine body 122 arranged on the top of the machine base 100, and the inside of the machine base 100 is provided with a sliding track groove A101 extending left and right. The rear end of the sliding track groove A101 is provided with a sliding track groove B104 extending left and right, the base 100 is provided with a cavity A111 located at the right end of the sliding track groove A101 and the sliding track groove B104, and the extrusion body 122 is provided with left and right pairs of sliding track grooves C120, the inner wall of the bottom of the sliding track groove C120 is connected with an arc-shaped gear groove 121 extending along it, and the inner wall of the rear end of the sliding track groove C120 is connected There is a cavity B128, the bottom end of the cavity B128 is connected to the top inner wall of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap