Underwater cutting jig frame

An underwater cutting and tire frame technology, which is applied in welding/cutting auxiliary equipment, auxiliary devices, plasma welding equipment, etc. Easy cleaning and maintenance, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

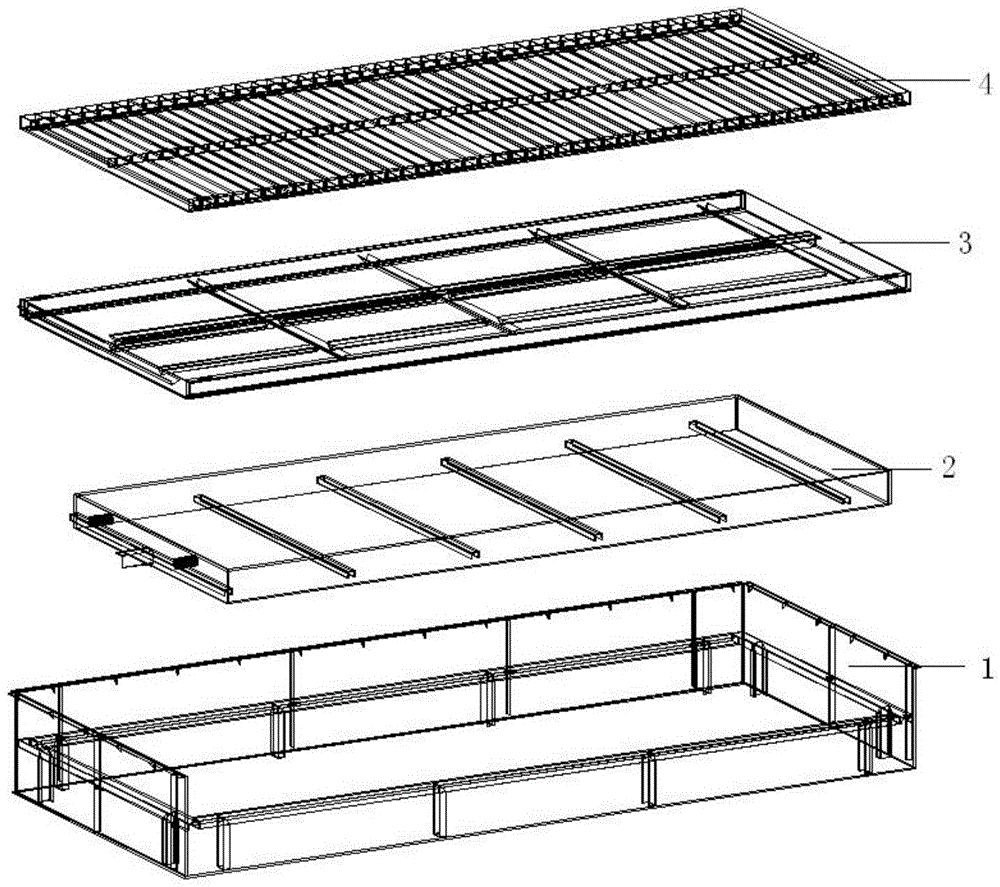

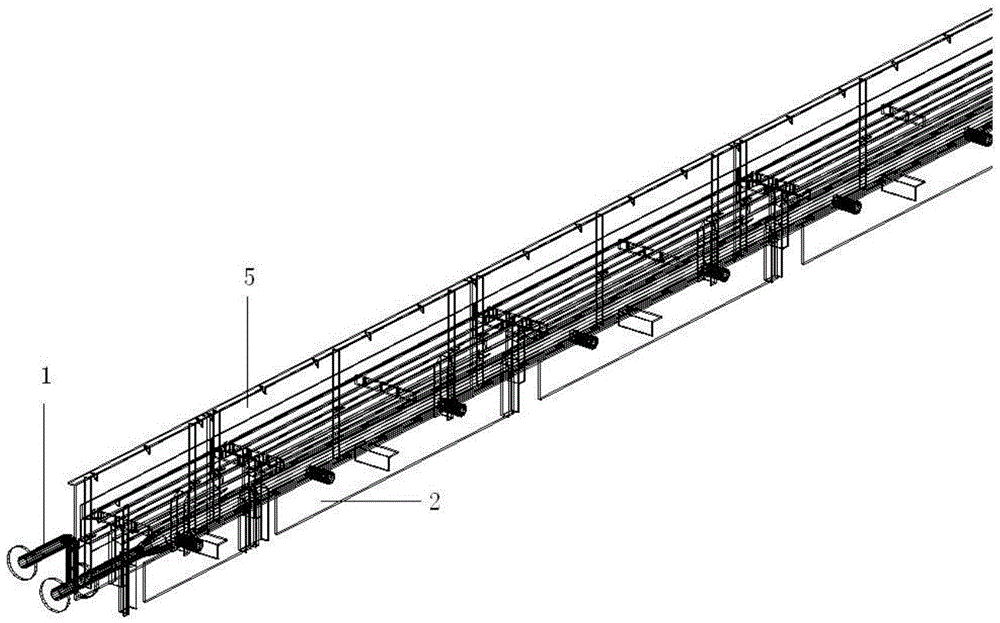

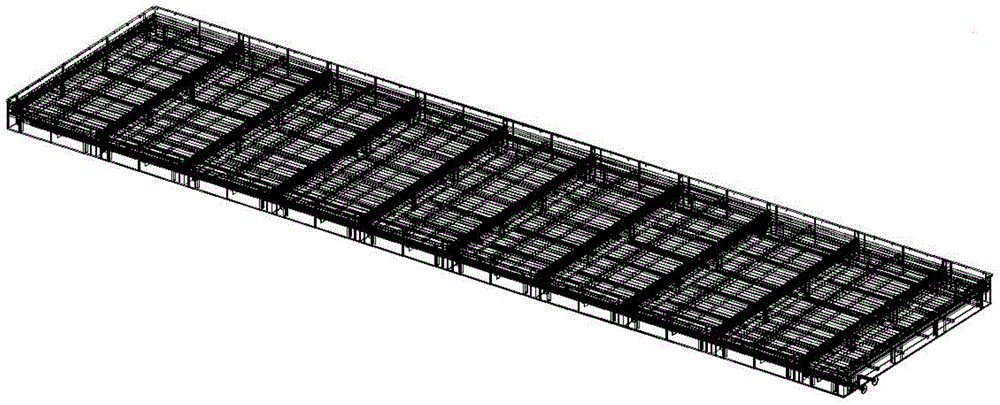

[0018] Such as figure 1 , figure 2 As shown, the present invention includes: a box body 1, wherein a platform is installed by welding in the middle of the box body 1, and a material rack 4 is installed on the platform; An air chamber 2 is buckled, and a bracket 3 is arranged above the air chamber 2 , and a material rack 4 is arranged above the bracket 3 .

[0019] The above-mentioned box 1 is a cuboid structure formed by 5 rectangular ribs connected by welding.

[0020] The above-mentioned platform is formed by welding the channel steel and the box body 1 .

[0021] The above-mentioned air chamber 2 is a cuboid structure formed by 5 rectangular ribs connected by welding, and its opening is provided with a channel steel every other section below the air chamber 2, and the side of the air chamber 2 is provided with a gas pipeline 5 Connected several air holes.

[0022] The above-mentioned support 3 is a rectangular structure formed by channel steel and connected by welding....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap