Perforated three-dimensional sheet material with double-side bulges and forming method thereof

A molding method and sheet technology, applied in the fields of sanitary products and medical products, can solve the problem of affecting the aesthetics of embossed and perforated three-dimensional non-woven fabrics, can not effectively improve the fluffy softness, affect the air permeability and liquid permeability of materials, etc. problem, to achieve the effect of improving dry performance, preventing being squeezed, and improving bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

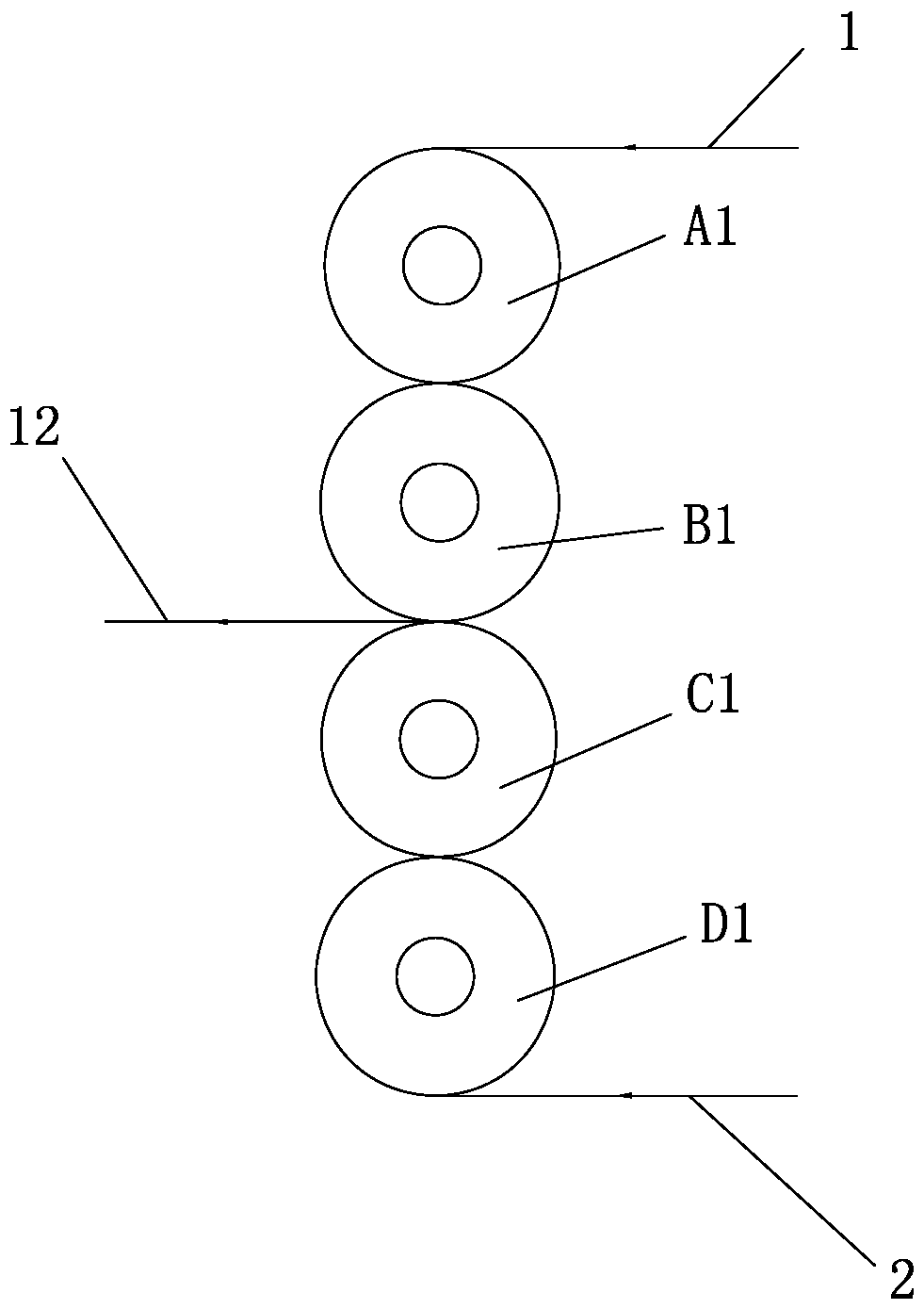

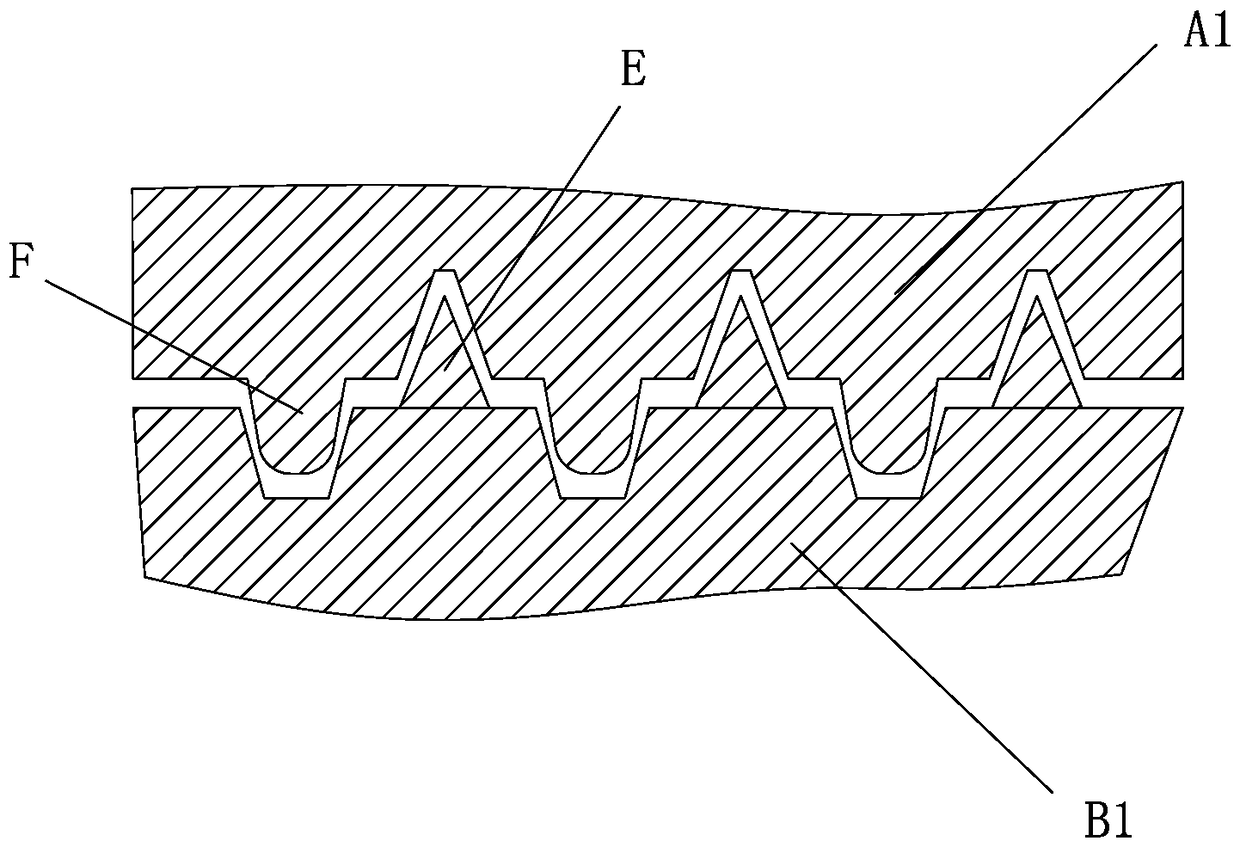

[0038] Such as Figure 1 to Figure 6 As shown, the first sheet 1 is embossed and perforated through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusion F on the first convex roller A1 is formed on the surface of the first sheet 1. convex a1, and the perforated needle E on the first concave roller B1 pierces the first sheet 1 to form an opening and the first sheet 1 is closely attached to the first concave roller B1, wherein: the first Sheet 1 is a 20gsm hydrophilic air-through non-woven fabric;

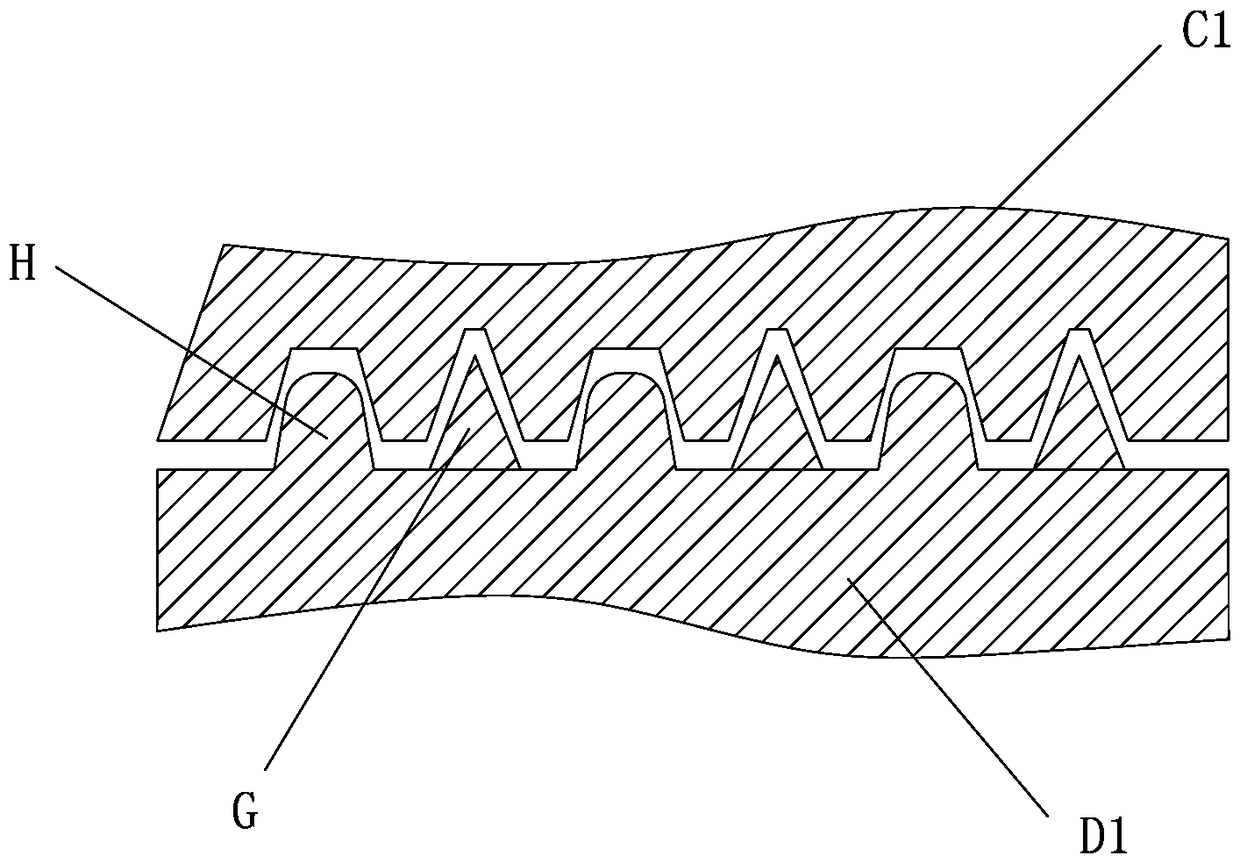

[0039] At the same time, the second sheet 2 is also embossed and punched through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusion H on the second convex roller D1 forms a downward convex on the surface of the second sheet 2. a1', and the perforated needle G on the second convex roller D1 pierces the second sheet 2 to form an opening, and the second sheet 2 is tightly attached to the second concave roller C1, wherein: the second Sheet ...

Embodiment 2

[0044] Such as Figure 7 to Figure 9 As shown, the first sheet 3 is embossed and perforated through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusions on the first convex roller A2 form an upward convex on the surface of the first sheet 3. a2, and the perforated needle on the first gravure roller B2 pierces the first sheet 3 to form an opening and the first sheet 3 is closely attached to the first gravure roller B2, wherein: the first sheet 3 is 18gsm hydrophobic air-through non-woven fabric;

[0045] At the same time, the second sheet 4 is also embossed and punched through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusions on the second convex roller D2 form lower protrusions on the surface of the second sheet 4. a2', and the perforated needle on the second convex roller D2 pierces the second sheet 4 to form an opening, and the second sheet 4 is closely attached to the second concave roller C2, wherein: the second sheet 4 is...

Embodiment 3

[0050] Such as Figure 10 to Figure 12 As shown, the first sheet 5 is embossed and perforated through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusions on the first convex roller A3 form an upward convex on the surface of the first sheet 5. a3, and the perforated needle on the first gravure roll B3 pierces the first sheet 5 to form an opening and the first sheet 5 is closely attached to the first gravure roll B3, wherein: the first sheet 5 is 22gsm PE perforated film sheet;

[0051] Simultaneously, the second sheet 6 is also embossed and punched through a pair of intermeshing concave-convex rollers. At 70-140°C, the protrusions on the second convex roller D3 form lower protrusions on the surface of the second sheet 6. a3', and the perforated needle on the second convex roller D3 pierces the second sheet 6 to form an opening, and the second sheet 6 is closely attached to the second concave roller C3, wherein: the second sheet 6 is 22gsm hydrophilic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com