Toothed railway wheel rail-toothed rail transition device

A rack and railway technology, which is applied to roads, tracks, buildings, etc., can solve problems such as safety accidents, large maintenance and repairs, and complex rotating arm mechanisms, and achieve the effects of strong stability, easy maintenance and repair, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

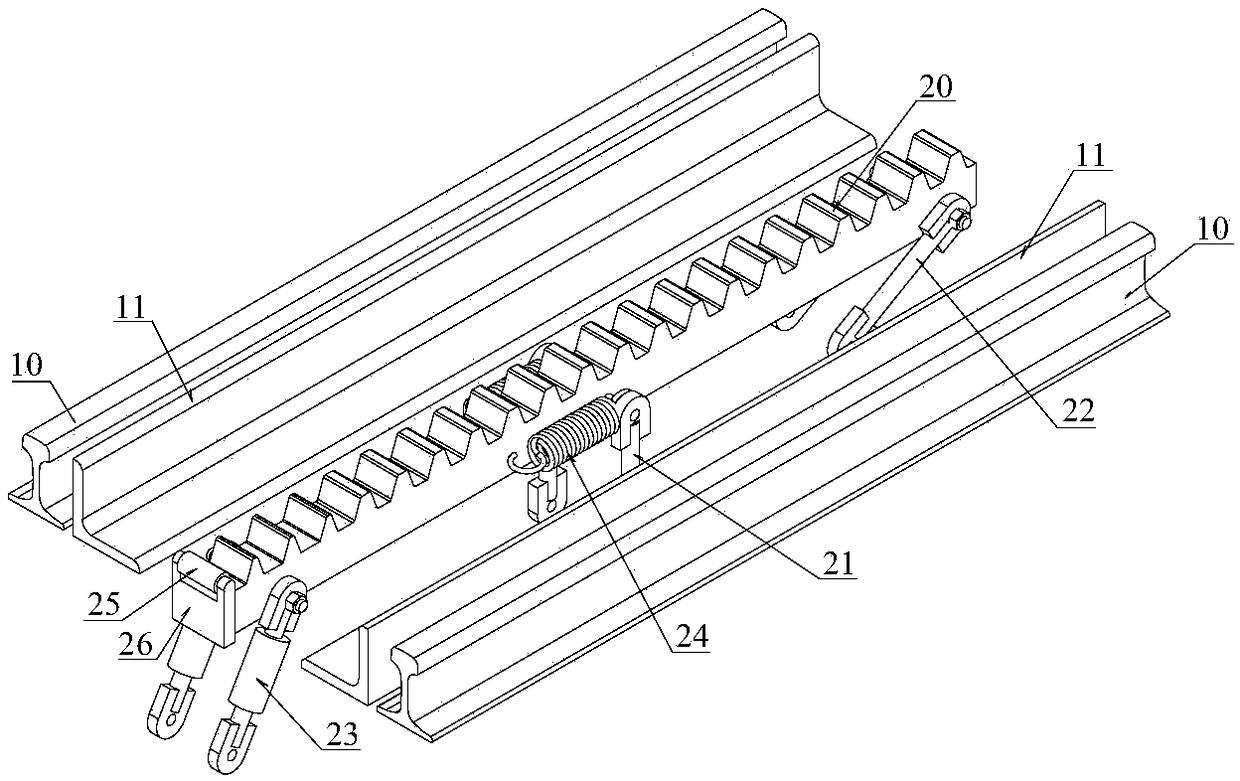

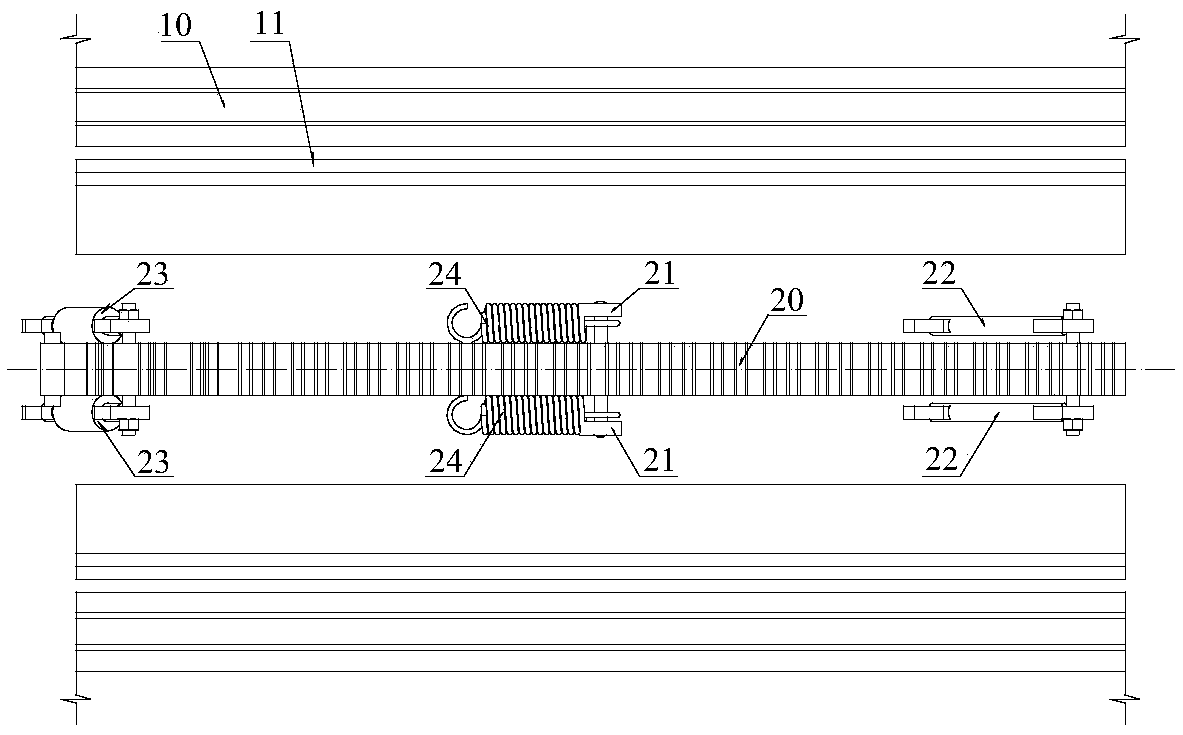

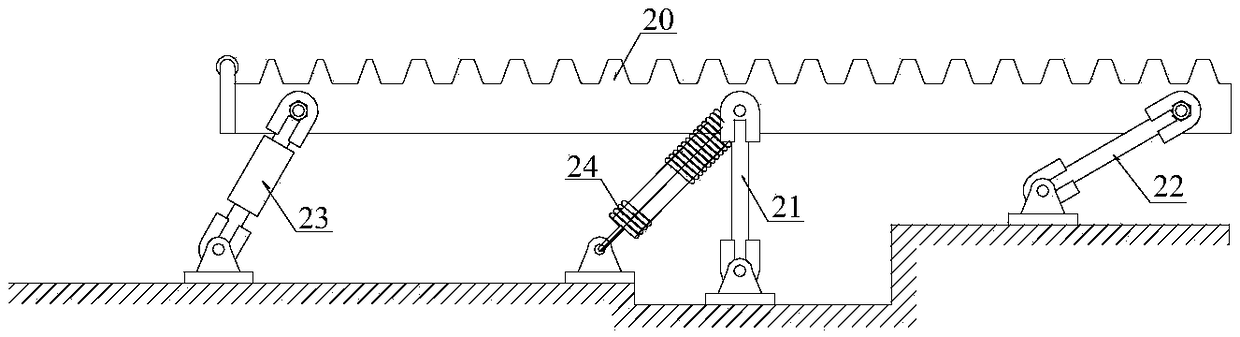

[0018] refer to figure 1 , figure 2 and image 3 , a cog railway wheel rail-cog rail transition device of the present invention includes a cog rail installed between the rails 10 on both sides. A transition section cog rail 20 is set before the entry end of the rack rail, a support arm 21 is set in the middle of the transition section cog rail 20, a hydraulic cylinder 23 is provided at the entry end, a rotating arm 22 is provided at the exit end, and a support arm 21 , the upper end of the hydraulic cylinder 23 and the pivoting arm 22 is hinged with the transition section rack 20, and the lower end is hinged with the foundation under the rail through the hinge seat; The two ends of the extension spring 24 respectively act on the transition section rack 20 and the under-rail foundation; the driving-in end of the transition section rack 20 is provided with a roller 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com