Sample storing and taking mechanical arm device

A technology of manipulators and driving devices, which is applied in the direction of manipulators, program-controlled manipulators, instruments, etc., can solve the problems of complex storage algorithms for delayed sample vials during database operations, impact on positioning accuracy and service life, frequent movements of manipulators, etc., and simplify information storage. Algorithm, ensuring positioning accuracy and service life, and shortening the effect of access operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

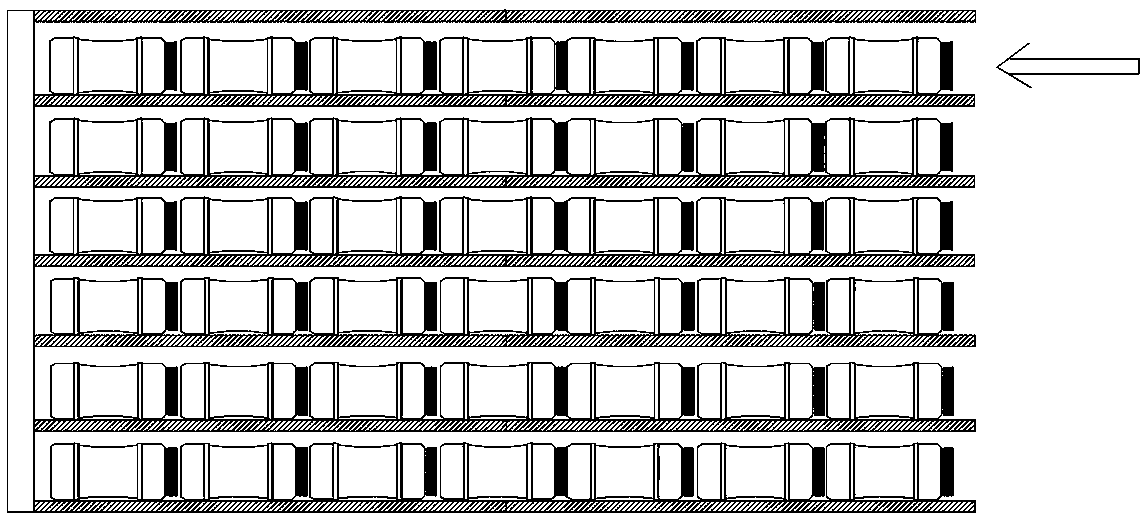

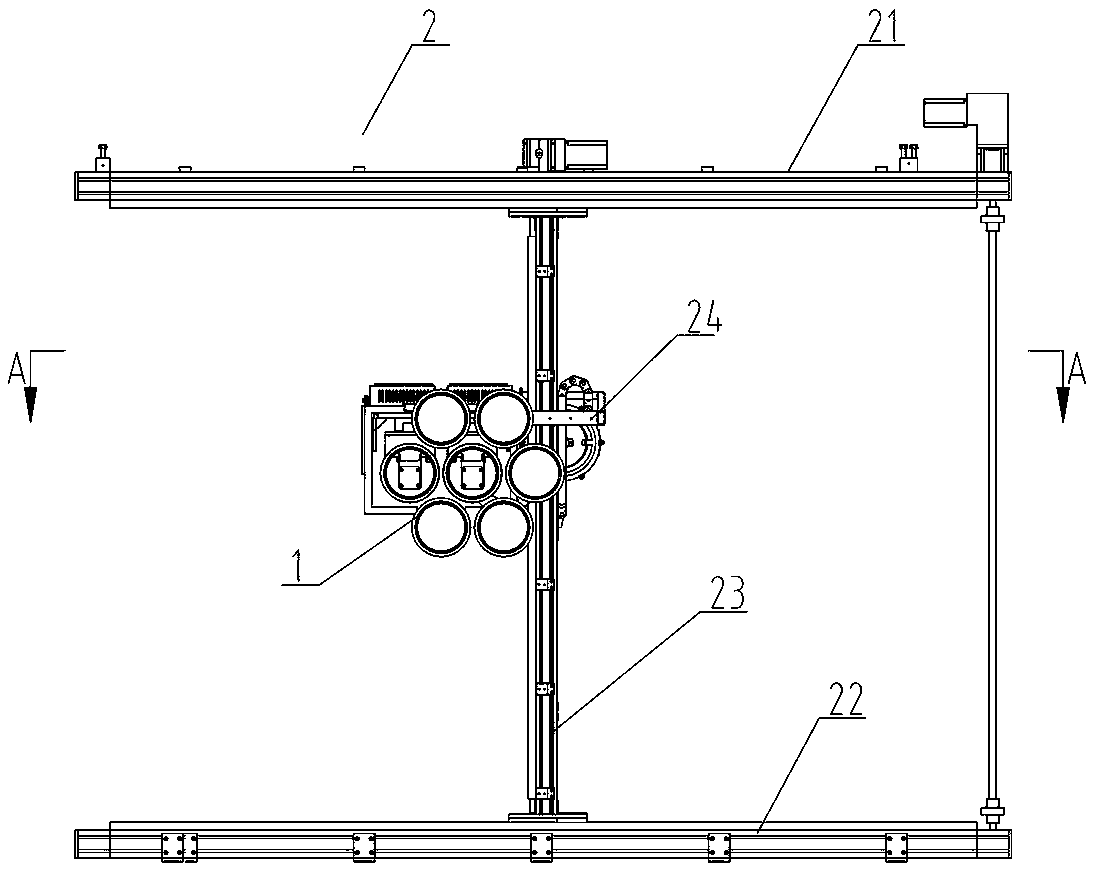

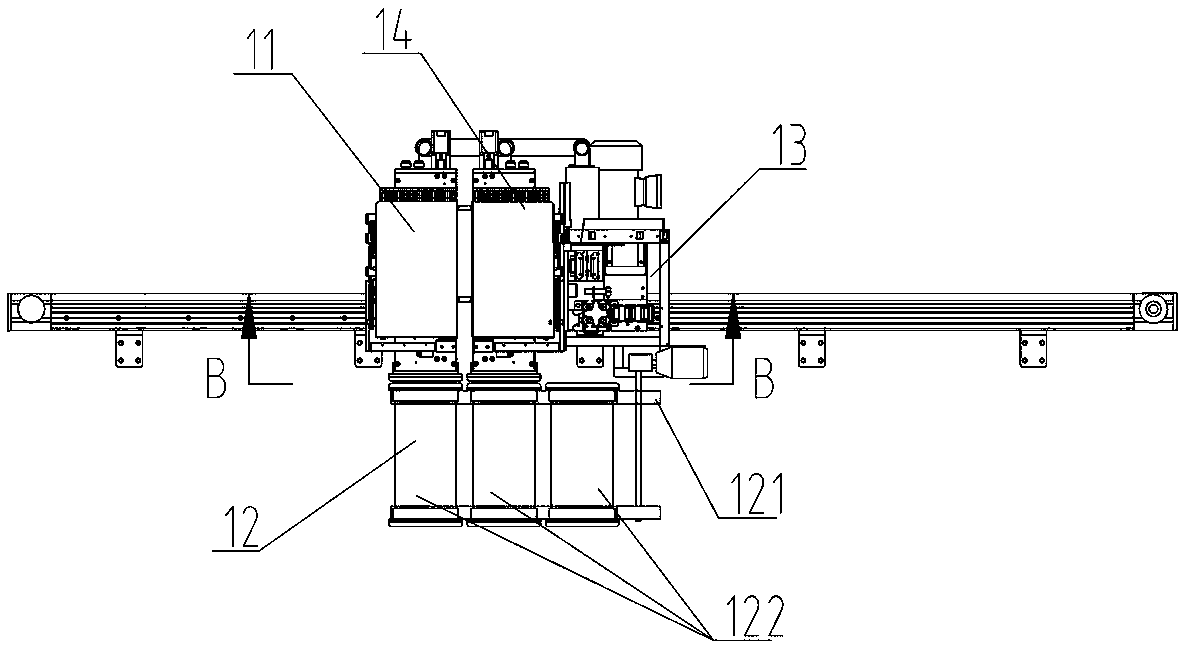

[0031] Such as Figure 2 to Figure 4As shown, the present invention provides a kind of depositing and sampling manipulator device, comprises manipulator 1 and is used for driving manipulator 1 to move at the driving device 2 of storage bottle station place, also is provided with control module (not shown in the figure; Of course, in In other embodiments, the control module can also be provided with control support by the whole set of storage and sampling system, instead of being separately configured on the storage and sampling robot device). The manipulator 1 includes a first access assembly 11 and a sample bottle compartment assembly 12. The sample vial compartment assembly 12 is provided with a moving bin driver 121 and a plurality of sample vial bins 122, and the shift bin driver 121 drives a plurality of sample vial bins 122 on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com