Double-capacity water drain valve

A drain valve, dual-capacity technology, used in water supply installations, flushing equipment with water tanks, buildings, etc., can solve problems such as valve seat damage, sealing performance decline, water waste, etc., to reduce impact force, reduce The effect of suction and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

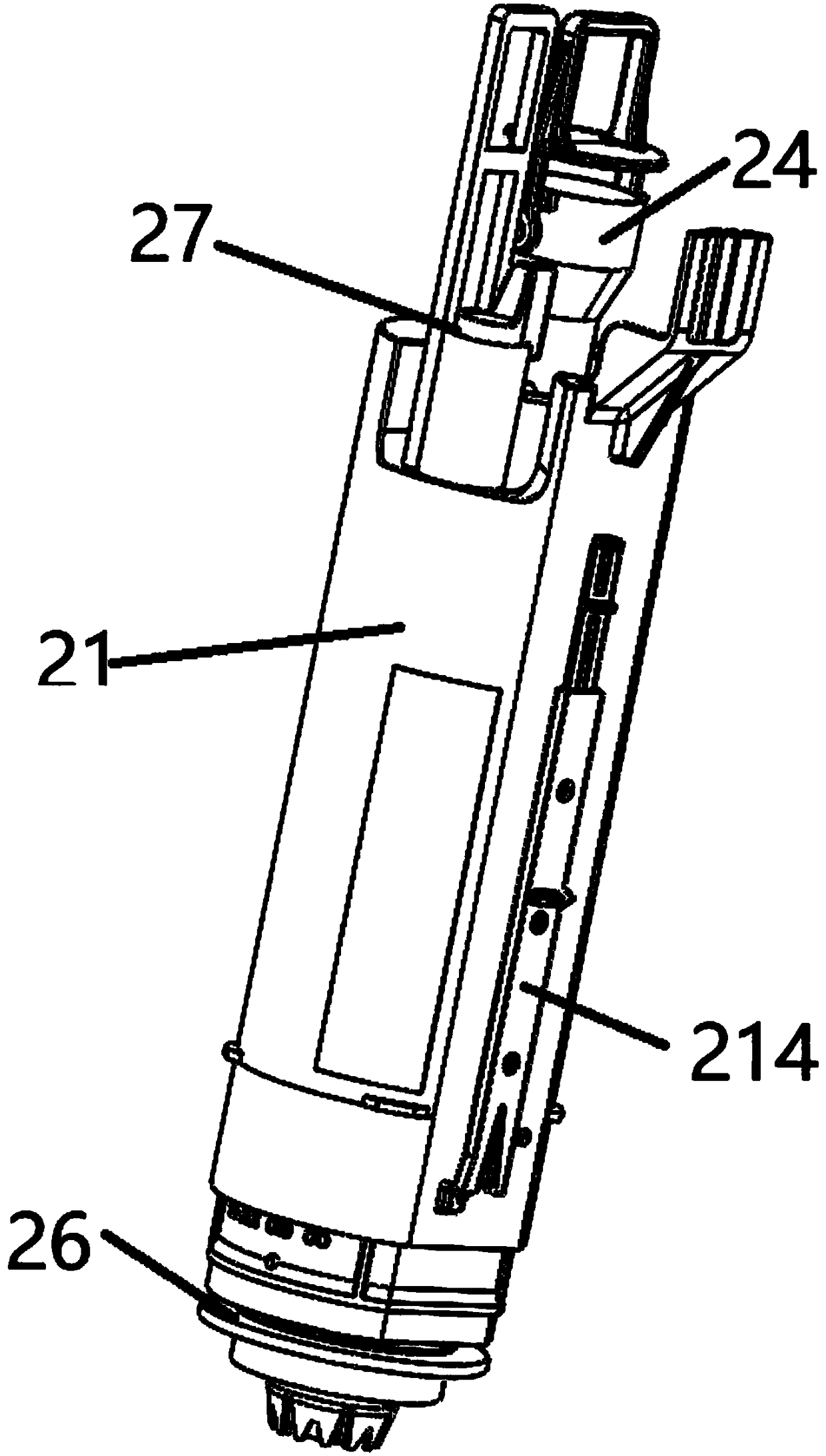

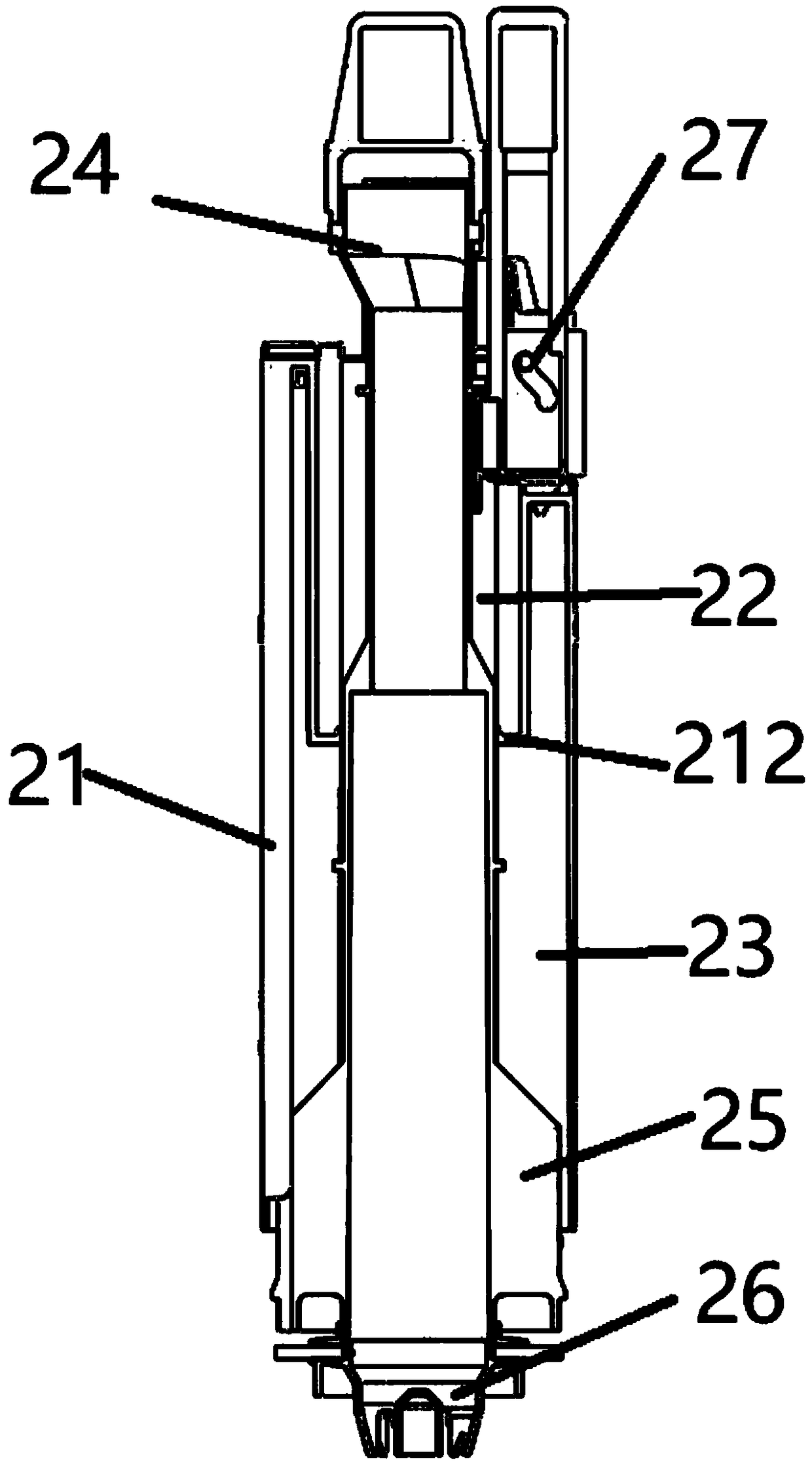

[0034] A double-capacity drain valve of the present invention, such as Figure 1-4 as well as Figure 10 As shown, it includes a valve seat 1 and a valve body 2, the valve seat 1 is in sealing connection with the bottom opening of the water tank (not shown), the valve body 2 is carried on the valve seat 1, and the valve seat 1 is opened and closed by the valve body 2, When opened, the water in the water tank flows out from the opening, and when closed, the water tank stores water. Wherein, the valve body 2 includes a cylinder body 21, and the cylinder body 21 includes a partition plate 212 with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap