A system for pre-tensioning a joint comprising a number of threaded elements

A technology of joints, threaded fasteners, applied in the direction of screwdrivers, wrenches, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

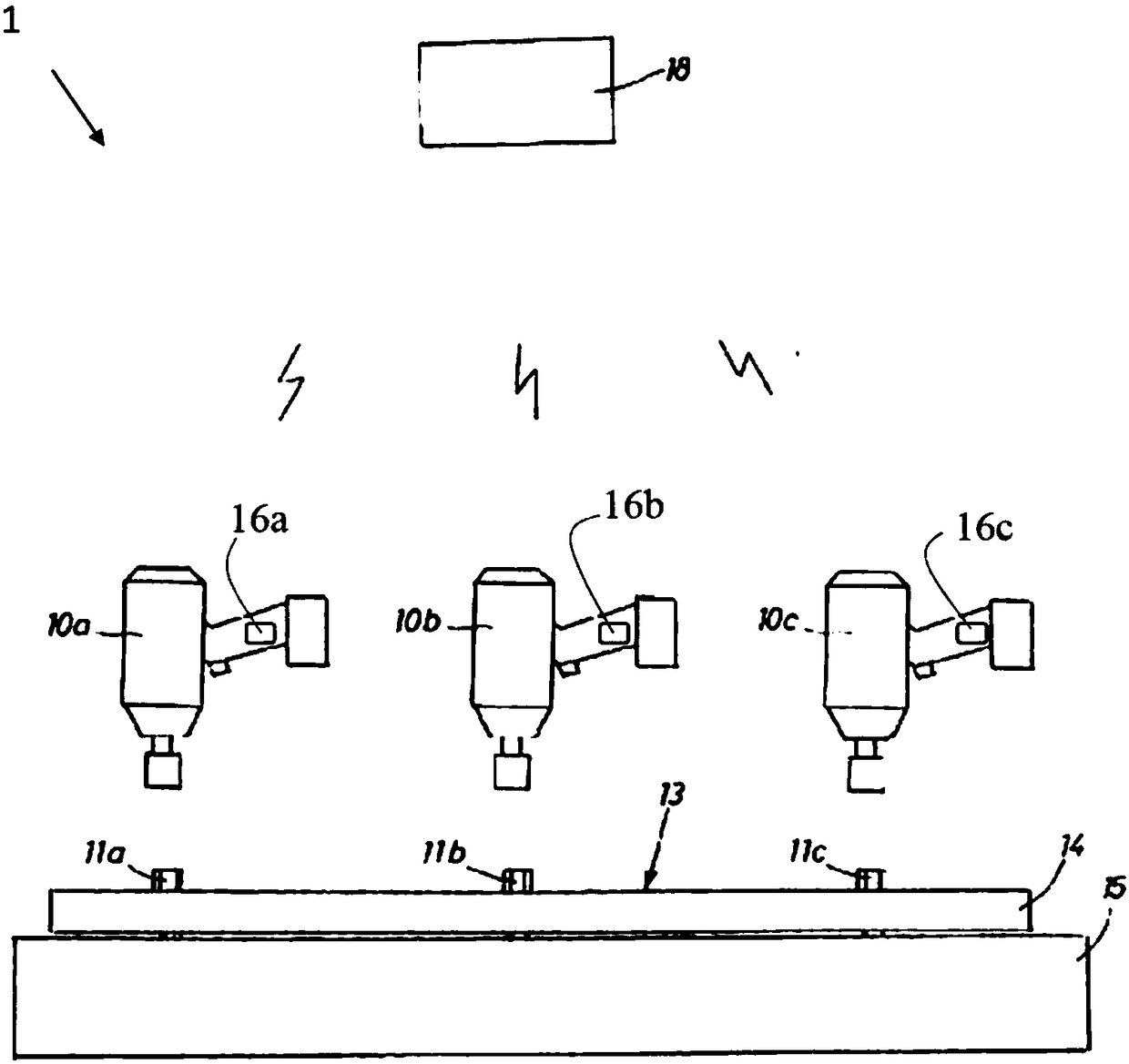

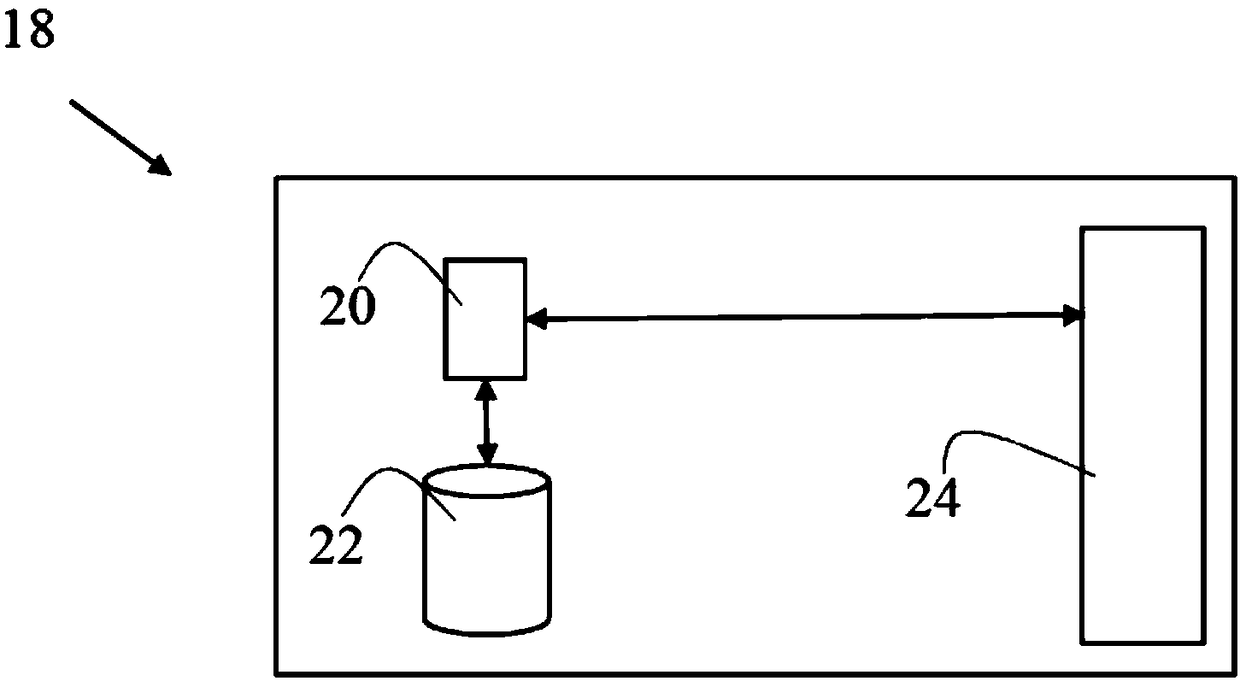

[0026] exist figure 1 , a system 1 for pre-tensioning a joint 13 comprising two or more threaded fasteners 11a-c by synchronous tightening of the threaded fasteners is shown. exist figure 1 The system shown in includes three manually supported and battery powered power wrenches 10a-c to be applied on a plurality of threaded fasteners 11a-c. The threaded fasteners 11a-c are part of the joint 13 in which the two elements 14, 15 are to be brought together by the clamping force obtained by the threaded fasteners 11a-c. Preferably, the power wrenches 10a-c are of the torque pulse transmission type, which does not generate any reaction force, enabling the operator to operate two wrenches simultaneously. But the power wrenches 10a-c could also be of the torque transmitting type. Each of the power wrenches 10a-c carries not only a removable battery housing, but also internal devices, not shown, for indicating actual operating data such as output torque, angular displacement, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com