Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as reducing lateral rigidity, achieve uniform circumferential rigidity, and improve the effect of snow-snow friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

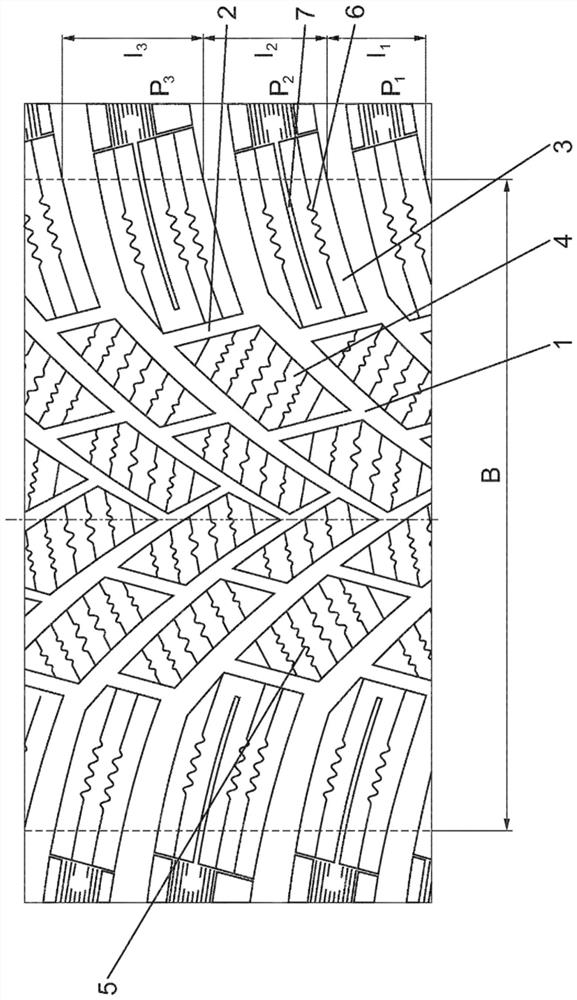

[0010] exist figure 1 The treads shown in are provided for winter tires or all-season tires for passenger cars, vans, etc. and are designed as a function of the direction of travel. Let B denote the width of the portion of the tread that is in contact with the ground, ie the width over which the tire contacts the ground when rolling. The portion of the tread that contacts the ground conforms to the ground contact area (Footprint) measured statically in accordance with the E.T.R.T.O.

[0011] In the embodiment shown, the tread is provided over its width B with diagonal grooves 1 extending V-shaped and divided into shoulders by circumferential grooves 2 extending between adjacent diagonal grooves 1 Side blocks 3 and a central block 4 arranged in the middle region of the tread. Diagonal sipe 1 is the main sipe of the tread and extends in the central region of the tread at an angle α of ≤ 60°, in particular 25° to 40°, with respect to the circumferential direction, in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com