A kind of rope groove processing machine tool

A technology for machining machine tools and rope grooves, which is applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problem of difficult control of rope groove accuracy, and achieve the effect of accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

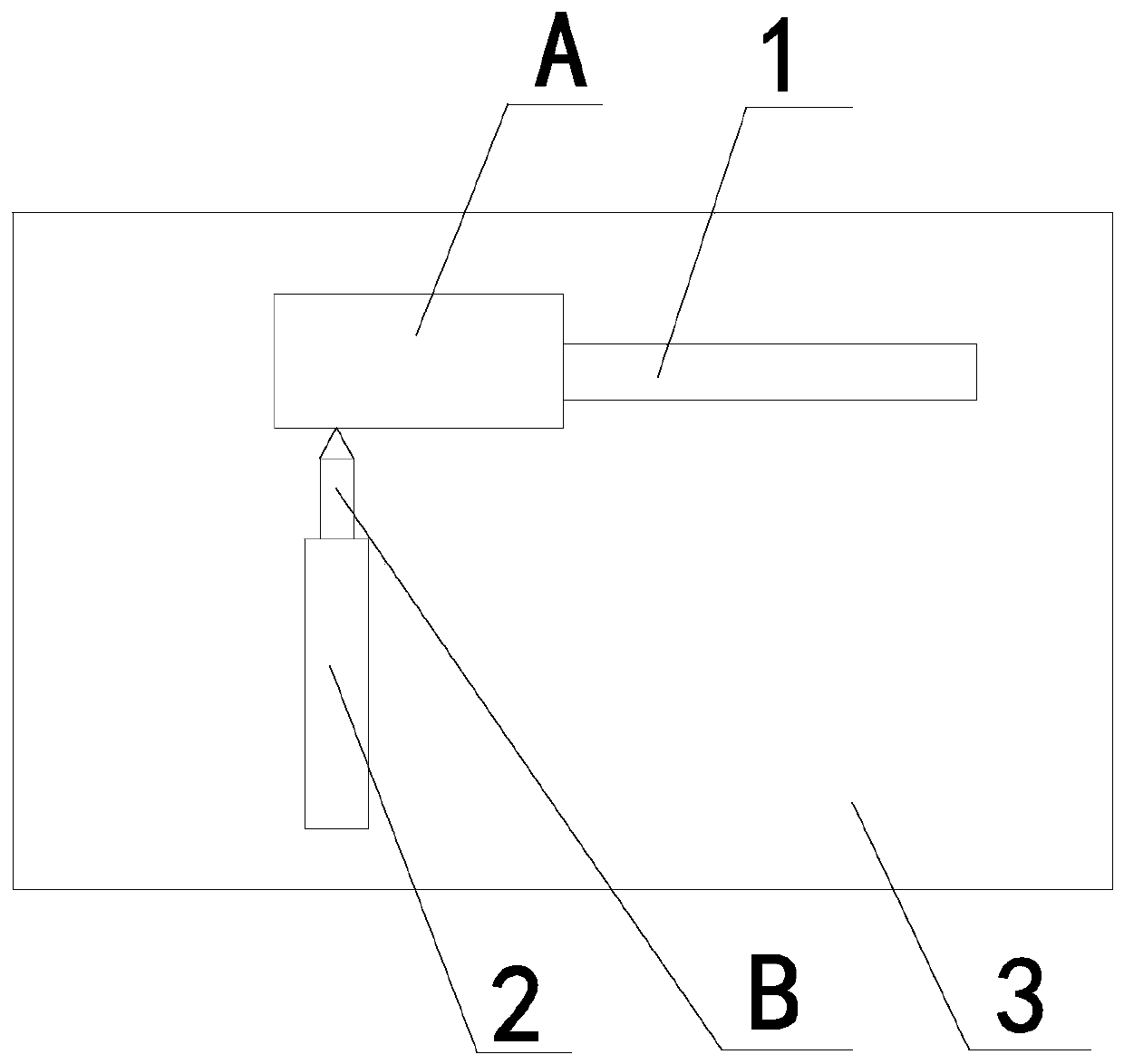

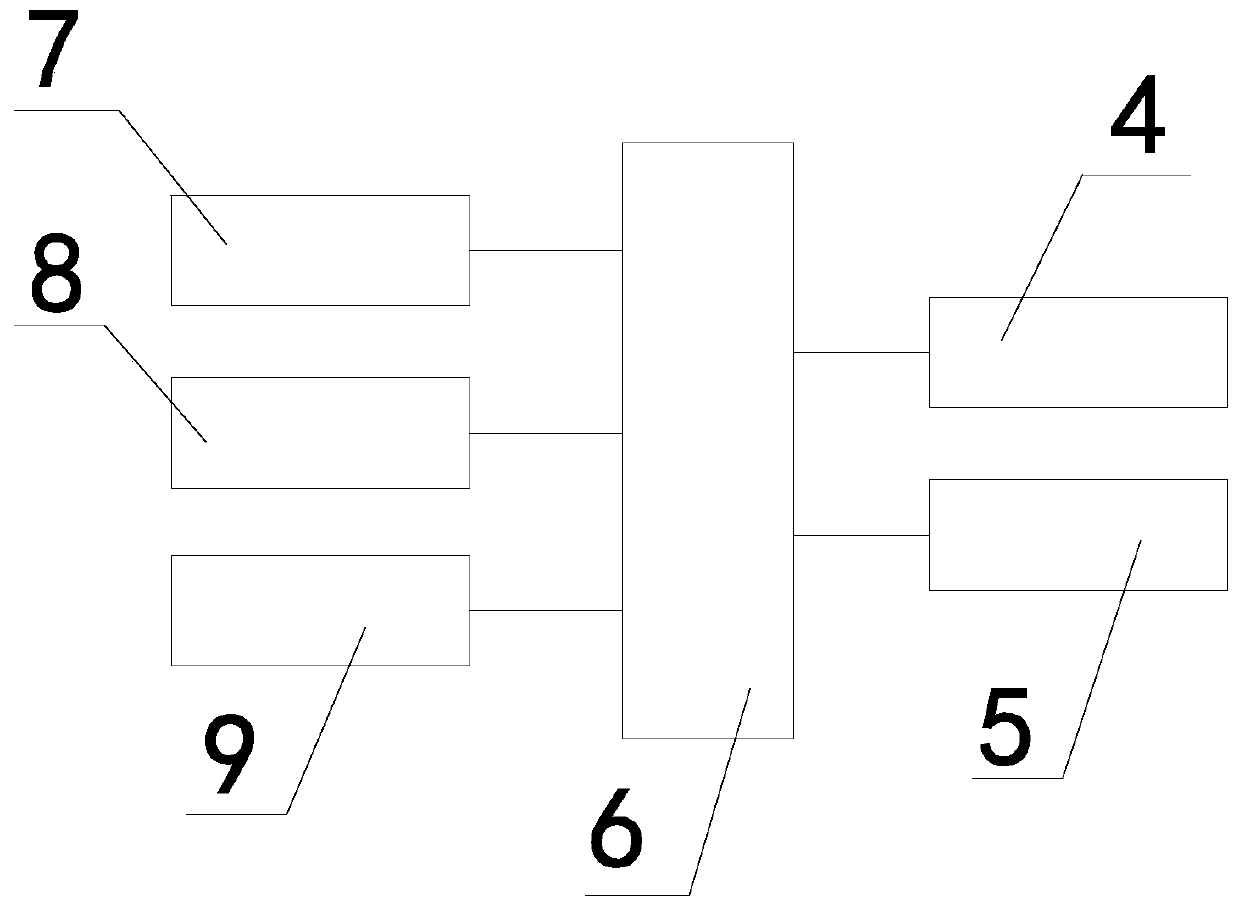

[0018] refer to figure 1 , a rope groove processing machine tool proposed by the present invention includes: a first feed shaft 1 , a second feed shaft 2 , a bed body 3 , a linear displacement sensor 4 , a rotary encoder 5 and a control module 6 .

[0019] The first end of the first feed shaft 1 is installed on the bed body 3 , and the second end thereof is used for clamping the workpiece A. The first feed shaft 1 is connected with a first drive mechanism 7 and a rotary drive mechanism 8, the first drive mechanism 7 is used to drive the clamping end of the first feed shaft 1 to reciprocate in a linear direction, and the rotary drive mechanism 8 is used to drive The first feed shaft 1 rotates around its center line. In this way, the workpiece A is clamped by the first feed shaft 1, which can drive the workpiece A to rotate and move linearly, laying a foundation for the processing of the rope groove.

[0020] In this embodiment, the first feed shaft 1 is a telescopic structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com