Full-automatic waterproof plug penetrating work station

A waterproof plug and workstation technology, applied in the field of wires and cables, can solve the problems of lack of versatility, time-consuming replacement, wear and tear of waterproof plug expansion pipes, etc., and achieve the effect of solving easy breakage, improving wearing quality, and reducing replacement frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

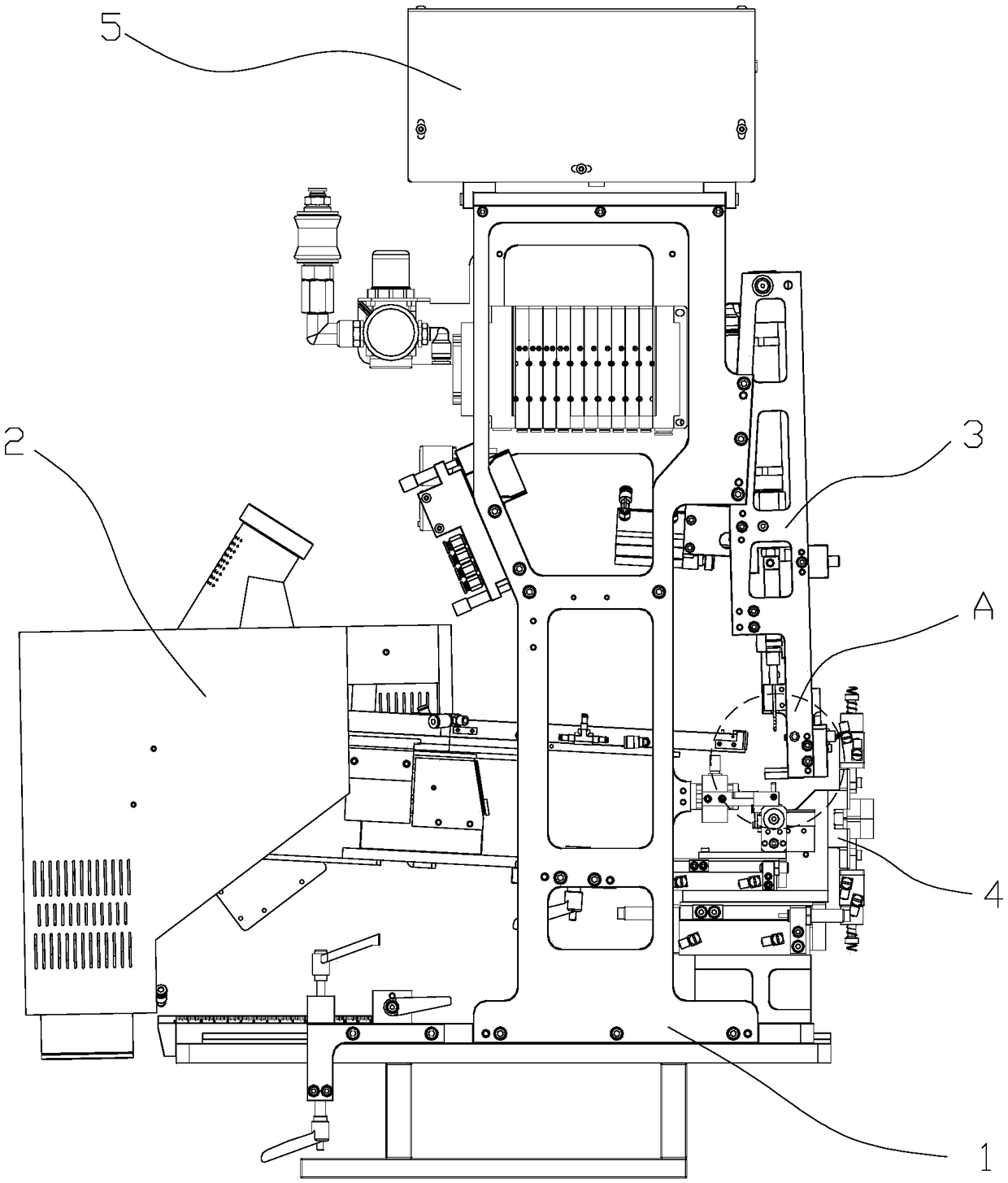

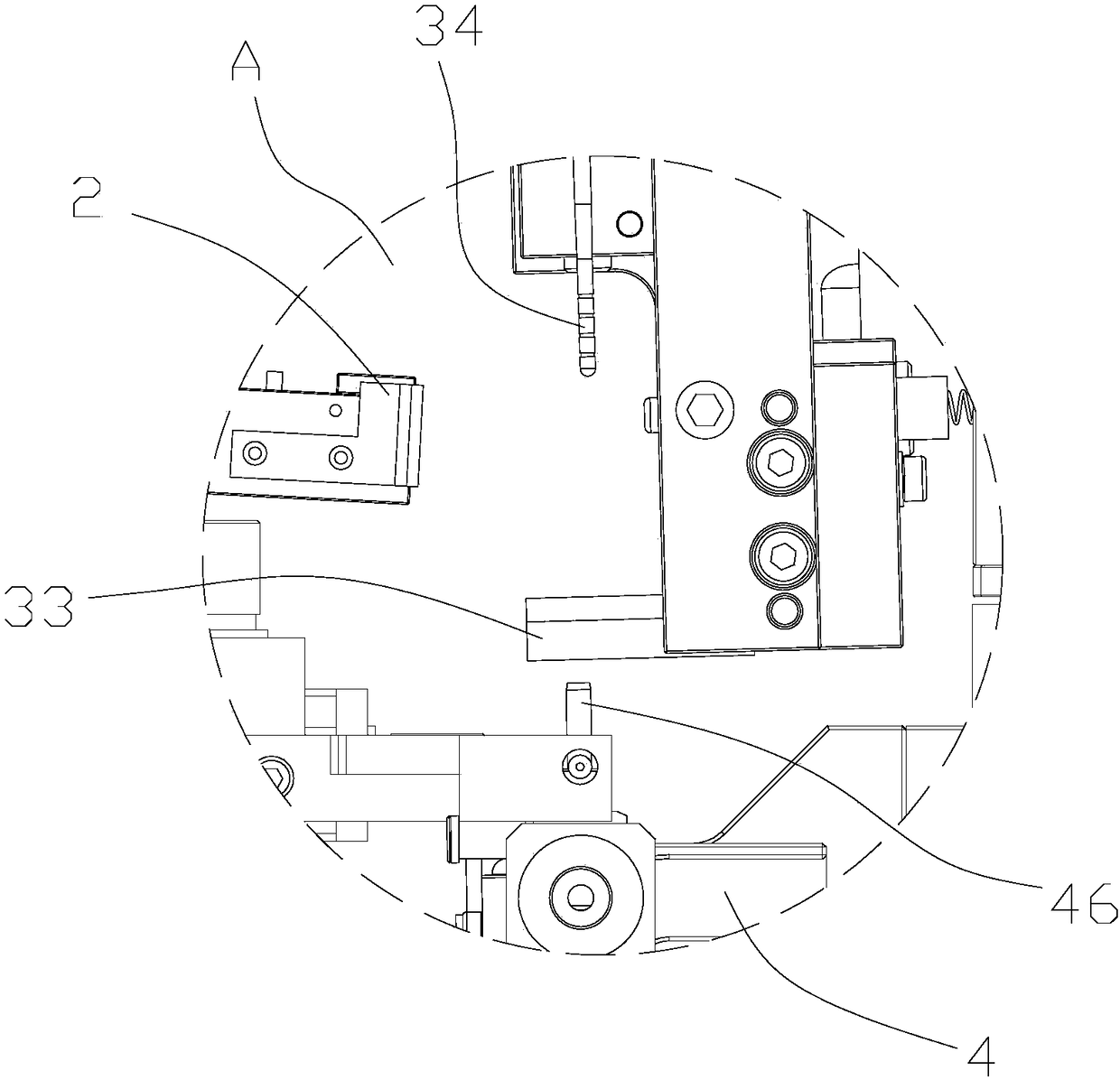

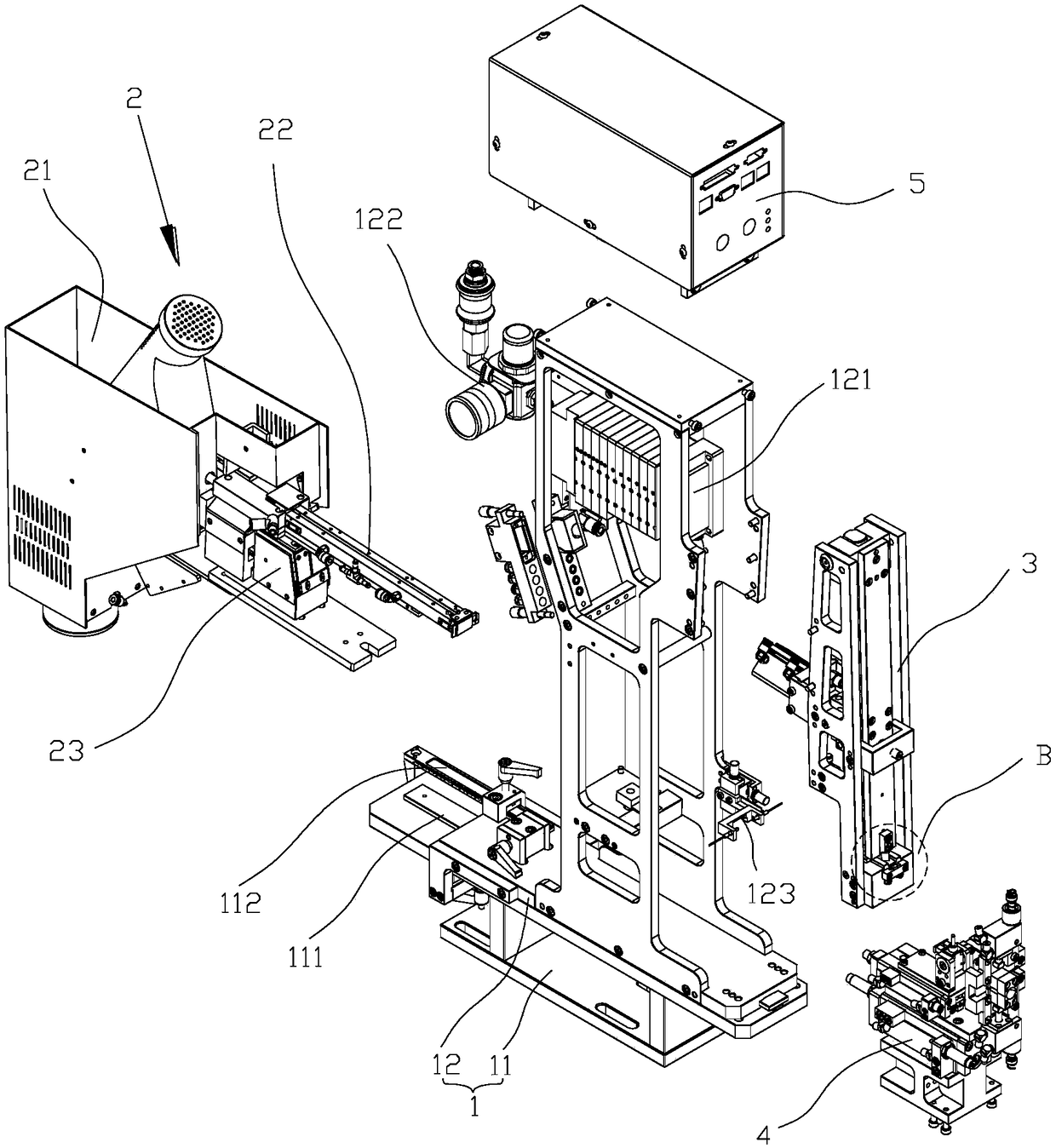

[0031] refer to figure 1 and image 3 , the embodiment of the present invention provides a fully automatic waterproof plug wearing workstation, including a frame component 1, a waterproof plug finishing component 2, a waterproof plug taking component 3, a pushing component 4 and a control box 5; the waterproof plug finishing component 2 is installed At the front end of the frame component 1, it is used to absorb the waterproof plug under negative pressure and then organize and transport it to the position where the waterproof plug is taken at the right end. Remove the waterproof plug from above and transfer the waterproof plug to the pushing assembly 4, the pushing assembly 4 is installed under the taking waterproof plug assembly 3 for wearing the waterproof plug on the wire harness, the control box 5 Install the top of the frame assembly 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com