Perforating device for door panel processing

A technology for punching equipment and door panels, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as affecting punching, inability to fix door panels well, and reducing work efficiency of staff, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

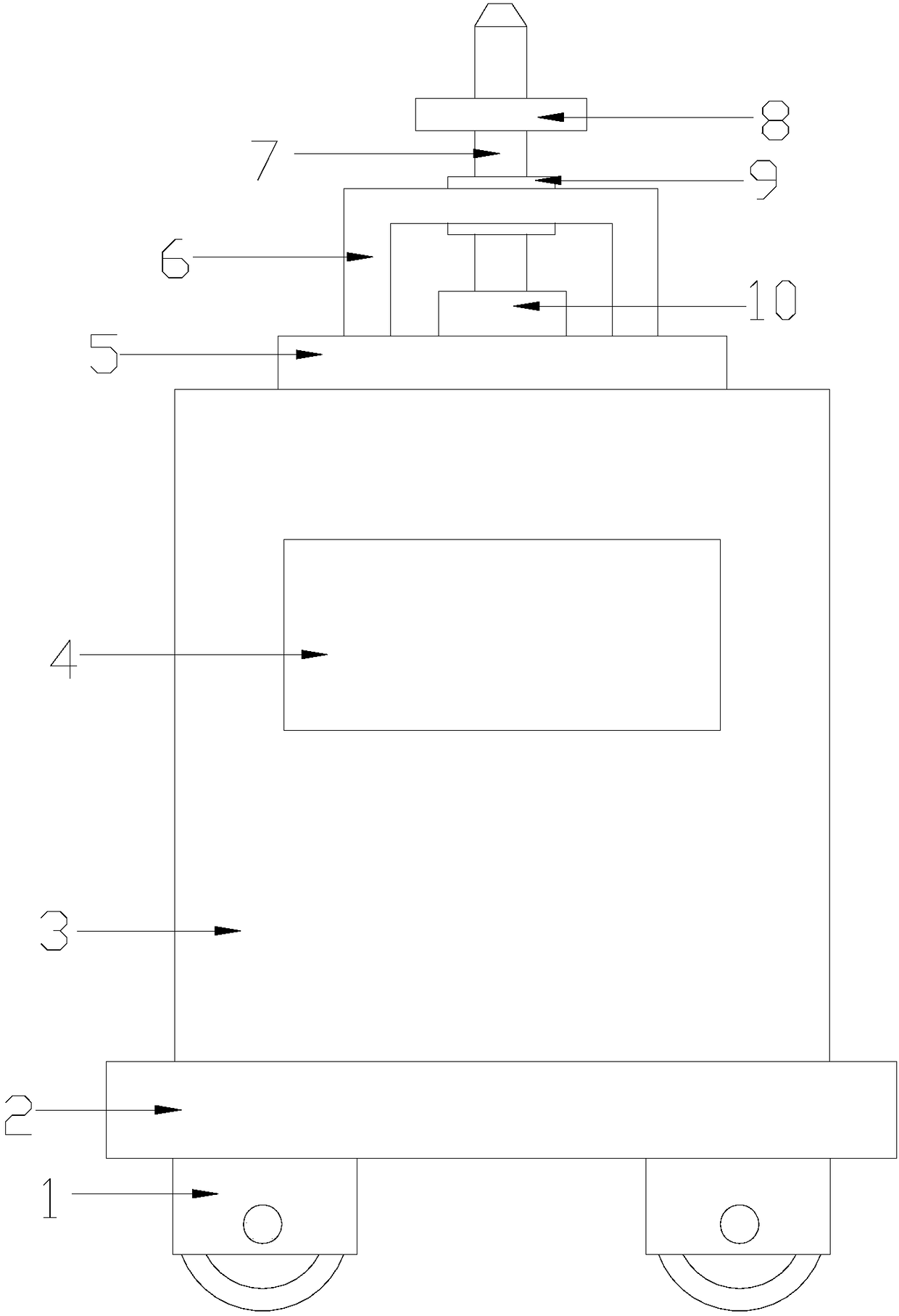

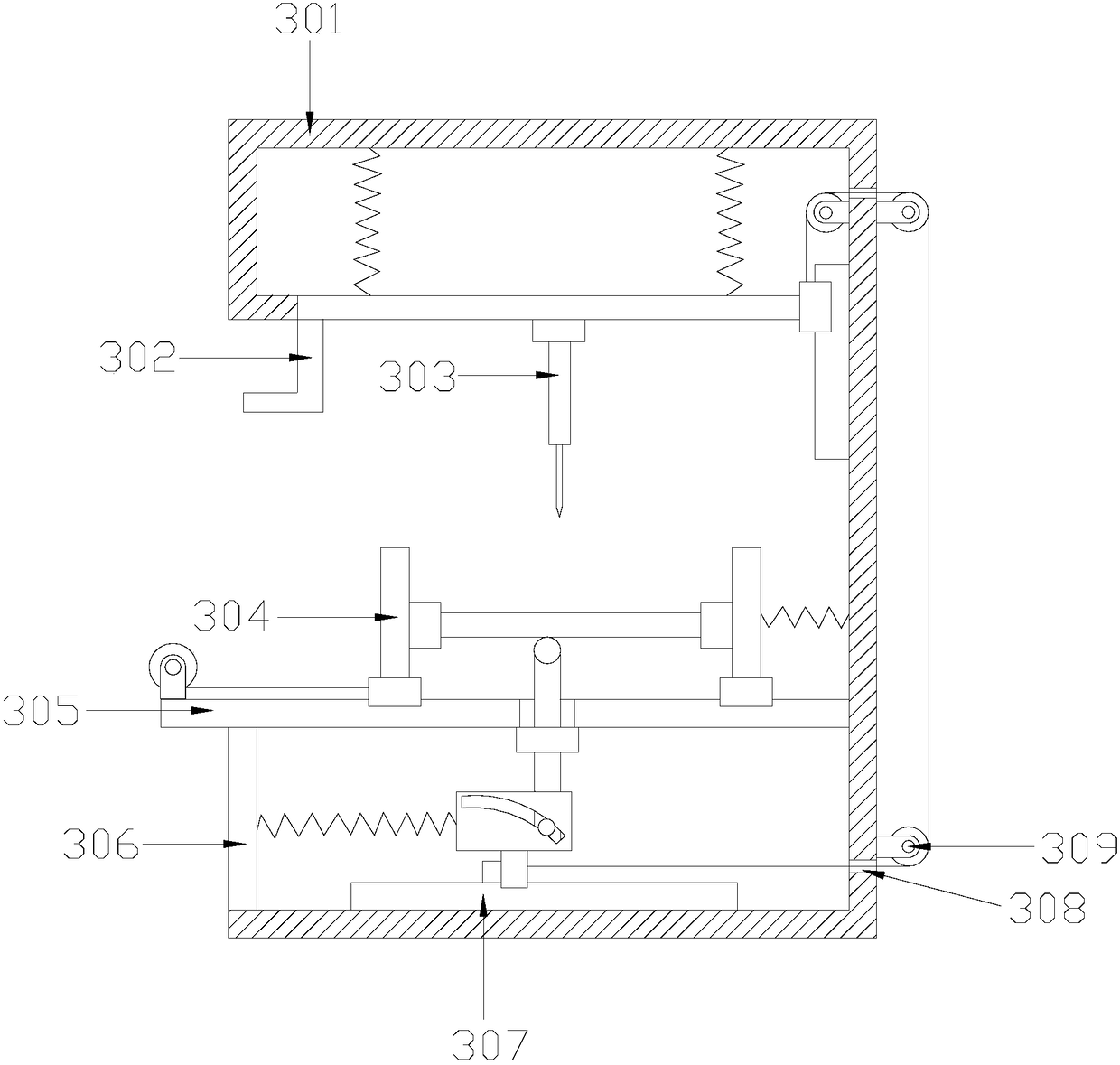

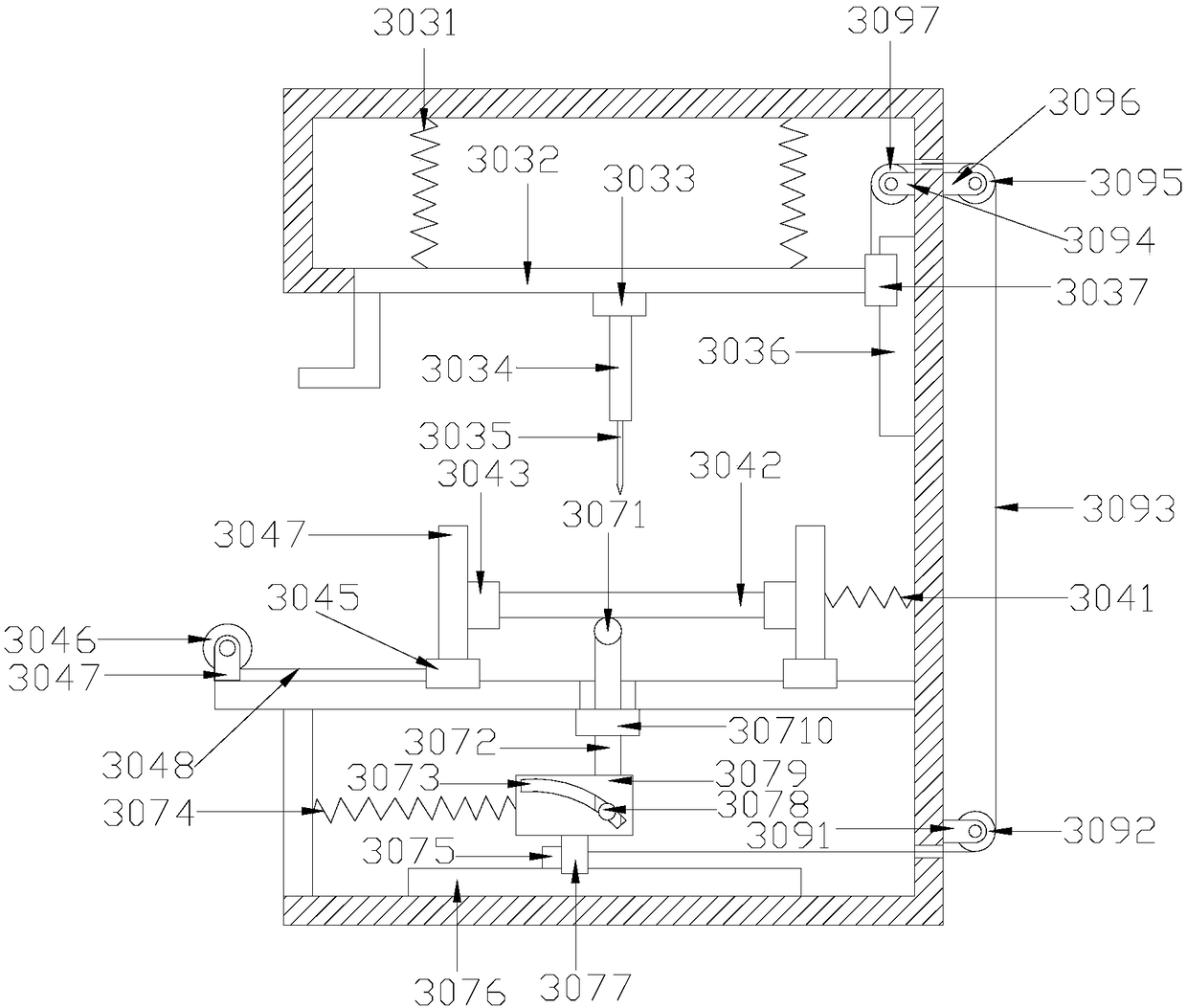

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a kind of punching equipment for door panel processing. Head 7, connecting plate 8, connecting sleeve 9, sleeve 10, the universal wheel 1 is provided with more than two and the upper end is fixedly welded to the bottom of the fixed base 2, and the bottom of the efficient and durable punching mechanism 3 is fixedly welded to the fixed base The upper end of 2 is reinforced and connected by screws, the rear end of the heat dissipation plate 4 is fixedly fastened to the front end of the efficient and durable punching mechanism 3 and the two are integrally formed structures, the bottom of the power box 5 is fixedly welded to the efficient and durable punching mechanism 3 The top is fixedly connected by positioning pins, the bottom of the U-shaped frame 6 is fixedly welded to the top of the power box 5, the bottom of the sleeve 10 is fixedly welded to the middle of the upper end of the power box 5, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com