Tire bladder mold

A capsule and mold technology, applied in tires, household appliances, other household appliances, etc., can solve the problem of uneven heating of the mold, and achieve the effect of ensuring stability and uniformity, simple structure, and ensuring uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

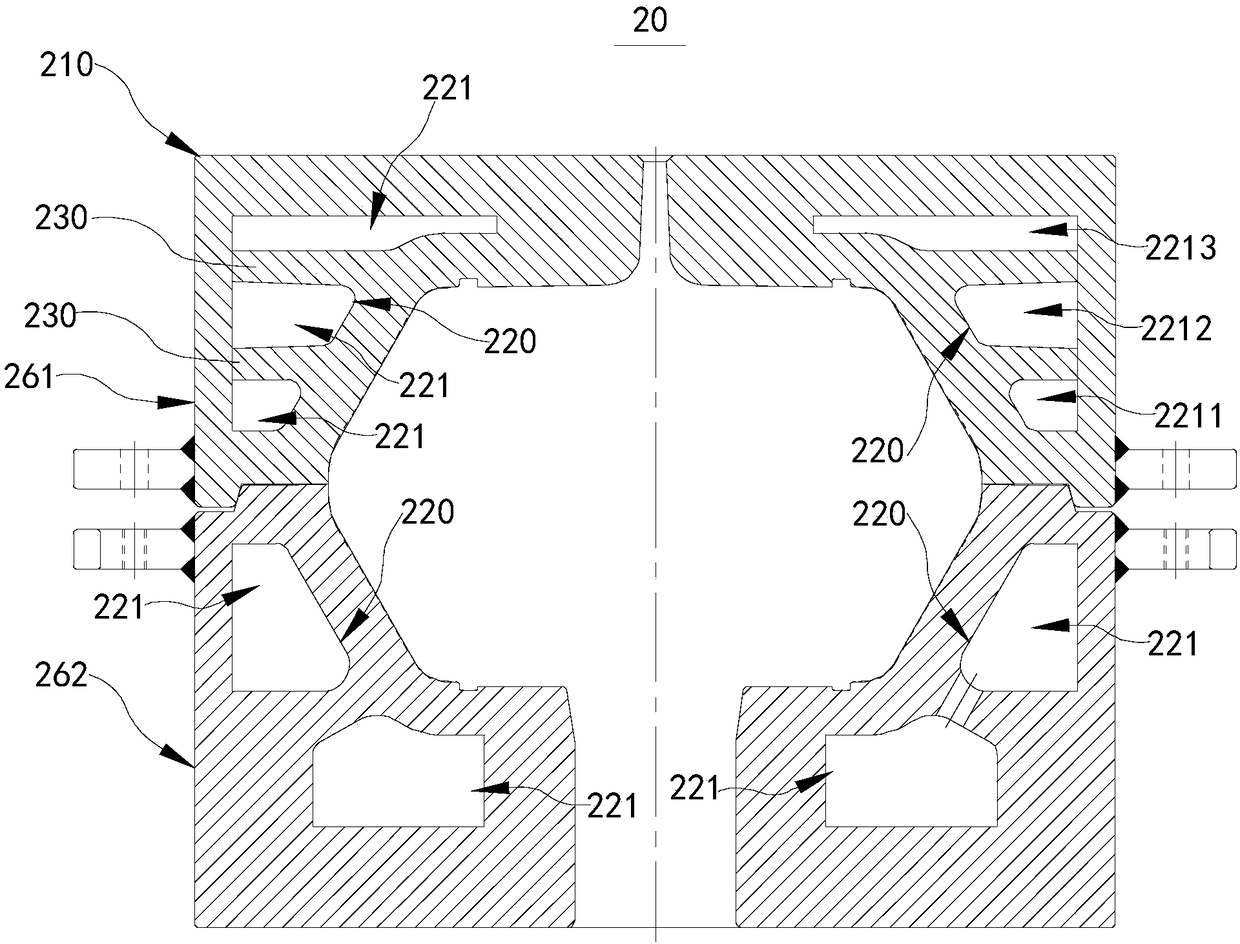

[0051] image 3 It is a schematic structural diagram of a tire bladder mold 20 provided by an embodiment of the present invention. Figure 4 for image 3 Schematic diagram of the structure from another perspective. Figure 5 for Figure 4 local schematic diagram. Please refer to Figure 3-Figure 5 , a tire bladder mold 20 includes a mold body 210 , an oil chamber cavity 220 , a horizontal plate 230 and a partition 250 .

[0052] The oil chamber cavity 220 is a hollow and airtight annular structure distributed along the circumference of the mold body 210 . The horizontal plate 230 divides the oil chamber cavity 220 into at least two annular sub-oil chambers 221 , and the plurality of sub-oil chambers 221 are distributed along the height direction of the mold body 210 . An oil inlet 241 is arranged on the side wall of the sub-oil chamber 221 near the lower end; an oil outlet 242 is arranged on the side wall of the sub-oil chamber 221 near the upper end. A communication pa...

Embodiment 2

[0085] Please refer to Figure 8 , Figure 8 A schematic structural view of the tire bladder mold 20 provided by this embodiment of the present invention.

[0086] Figure 8 A schematic diagram of the structure of the core mold 270 is shown in , and the structure of the core mold 270 is similar to that of the outer mold. The oil chamber cavity 220 of the core mold 270 is provided with a plurality of sub-oil chambers 221 from bottom to top, and adjacent sub-oil chambers 221 are communicated through communication channels 231 . Different from the outer mold, the oil inlet 241 of the sub-oil chamber 221 at the lower end of the mold body 210 is introduced from the axial direction of the center of the mold body 210; The central axial direction leads out.

[0087] The tire bladder mold 20 of the present embodiment of the present invention has at least the following advantages:

[0088] After entering from the oil inlet 241, the heating medium flows into the next sub-oil chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com