Drilling liner hanger controlled by surface bit weight and control method of drilling liner hanger

A technology of a liner hanger and a control method, which is applied in the field of oil and gas field drilling, can solve the problems that the pressure of the liquid column in the pipe cannot pass through the pressure transmission hole, and the liner hanger cannot be seated, so as to achieve reliable seating, avoid interference, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

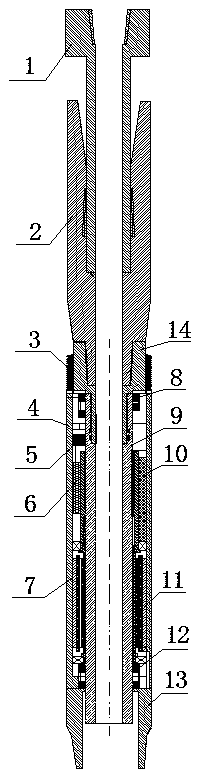

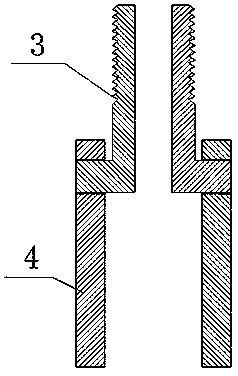

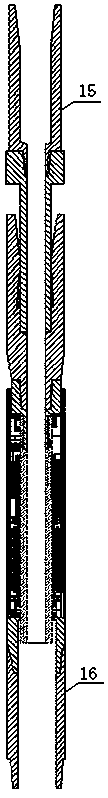

[0025] Such as figure 1 Shown is a liner 16 hanger controlled by the rotation of the drill pipe 15 on the ground, including a lifting short joint 1, a sealing joint 2, slips 3, a motor outer shell 4, a strain gauge 5, a downhole circuit board 6, and a motor rotor 7. Motor inner housing 9, downhole battery 10, coupling sleeve 11, lower joint 13 and upper joint 14, motor rotor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com