Hydraulic elevator

A technology of hydraulic lifting and machine base, which is applied in the fields of baking, dough processing, food science, etc., and can solve the problem of short shelf life of bread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

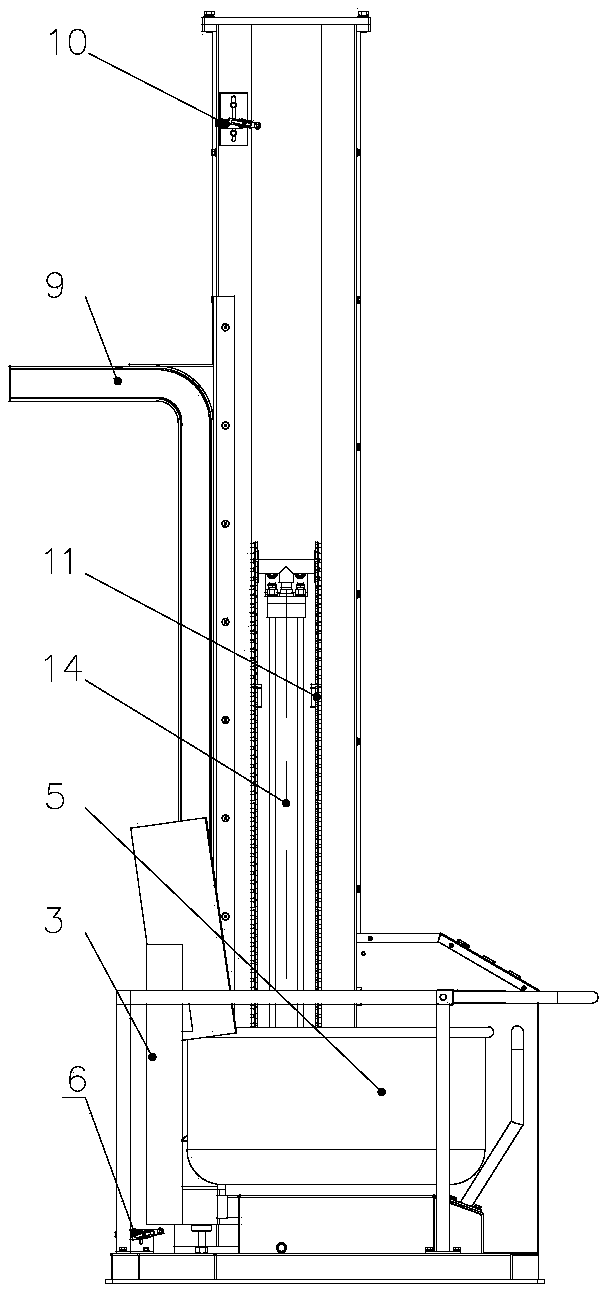

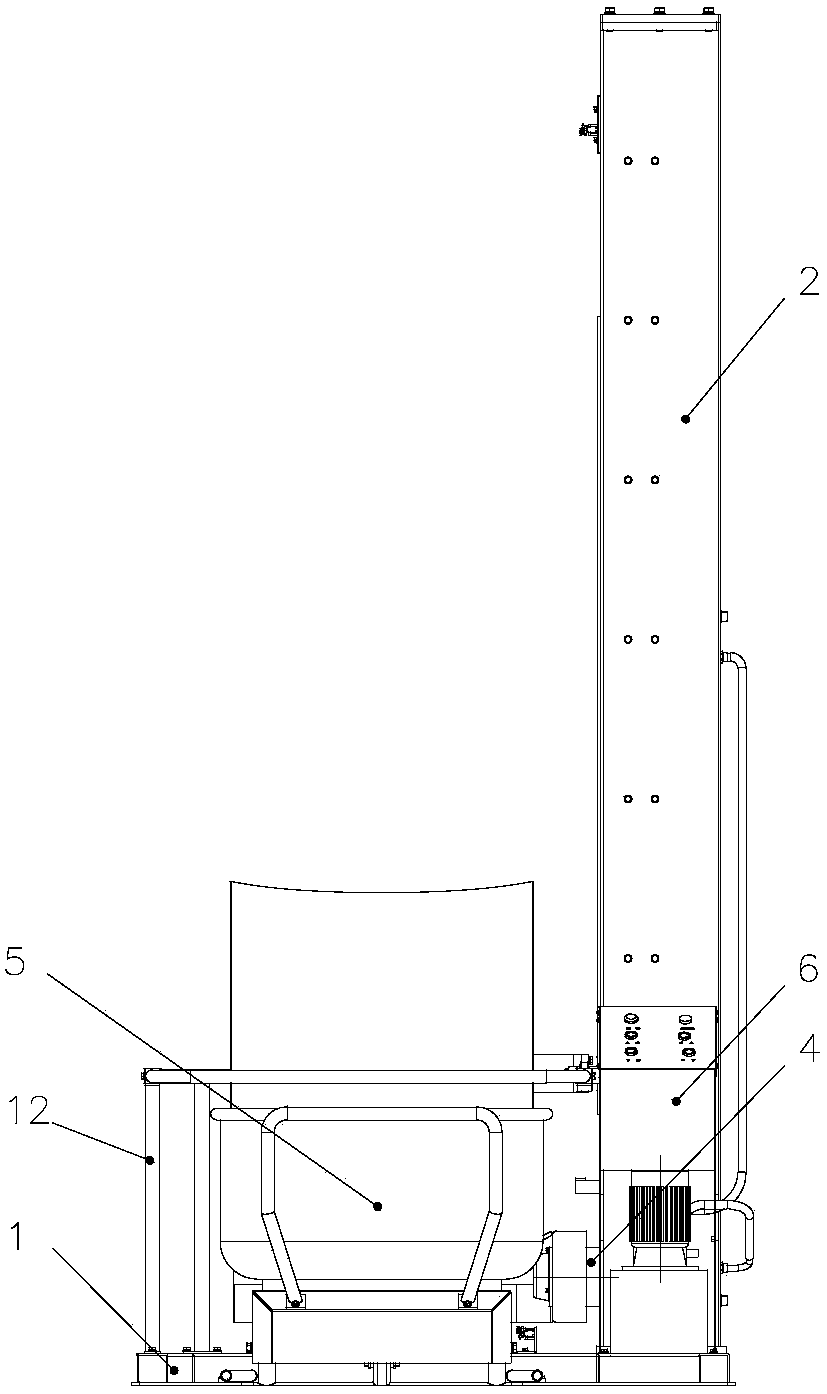

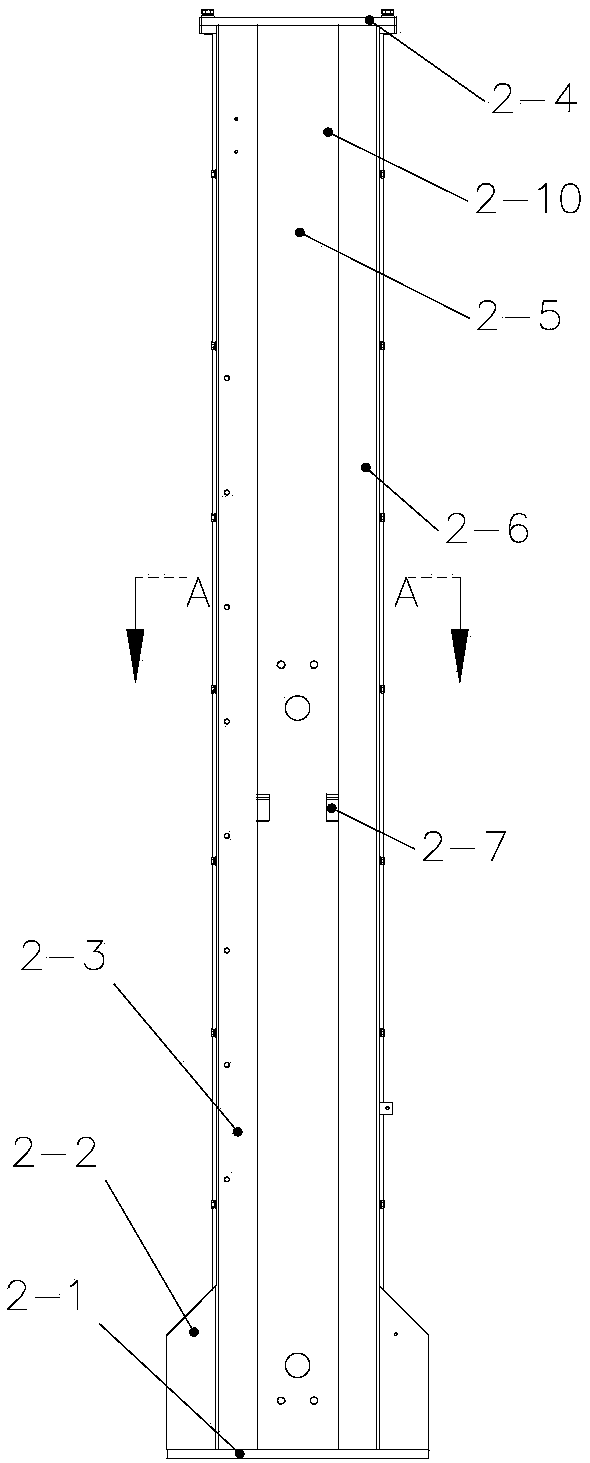

[0028] Such as Figure 1-11 As shown in one, the present invention discloses a hydraulic hoist, which includes a machine base 1, a trolley bucket assembly 5, a bucket fork frame 3 and a lifting guide frame 4, and the machine base 1 is provided with a trolley guide rod 1-4, the trolley bucket assembly 5 slides along the trolley guide rod 1-4 and is installed on the machine base 1, and is detachably connected with the bucket fork frame 3. One side of the machine base 1 is fixed with a column 2, and the column 2 Corresponding to the side of the machine base 1, there is a guide groove. The guide groove of the column 2 is equipped with a guide rail 2-9. The lifting guide frame 4 slides along the guide rail 2-9 and is installed in the guide groove 2-10. The fork frame 3 is detachably connected, and the lifting guide frame 4 is driven up and down by a hydraulic cylinder, and the hydraulic cylinder is controlled by an electric control cabinet 6 . The hydraulic system that the present...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap