A kind of three-dimensional fabric reinforced phenolic resin composite material and its preparation method

A technology of phenolic resin and three-dimensional fabric is applied in the field of three-dimensional fabric reinforced phenolic resin composite material and preparation, which can solve the problems of slow resin flow, low resin flow and mold filling efficiency, and scrapped components, so as to reduce pores, improve RTM molding efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

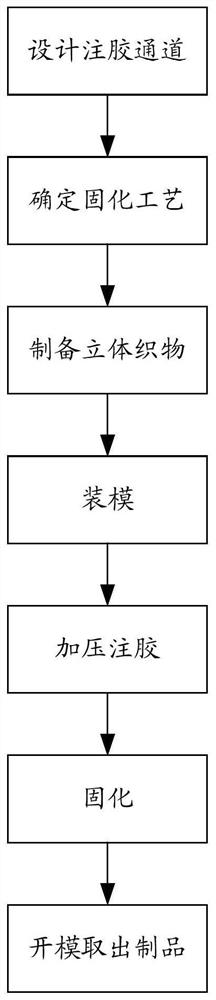

[0045] A 30mm thick three-dimensional braided fabric reinforced flat structure is fabricated, and the flat size is 200×200mm. The specific preparation process is as figure 1 Shown:

[0046] 1. Design the injection channel

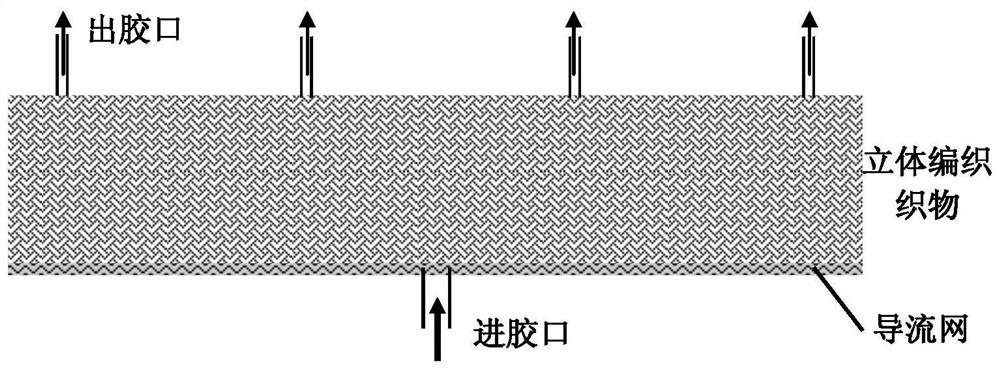

[0047] Such as figure 2 As shown, the thickness direction of the three-dimensional fabric is the glue injection direction, and the guide net is designed at the glue injection port, and the glue outlet is evenly designed on the non-working surface of the three-dimensional fabric.

[0048] 2. Design curing process

[0049] according to Figure 5 The schematic diagram of the rheological characteristic curve and the curing temperature of the phenolic resin (brand name FQ190 of the Institute of Chemistry) are shown, and the temperature T of the rapid rise period of the resin viscosity is determined. ns 100°C, curing temperature T gh 160°C, design 2 heat preservation and exhaust steps between 100°C and 160°C, respectively 120°C and 140°C, keep heat at 100°...

Embodiment 2

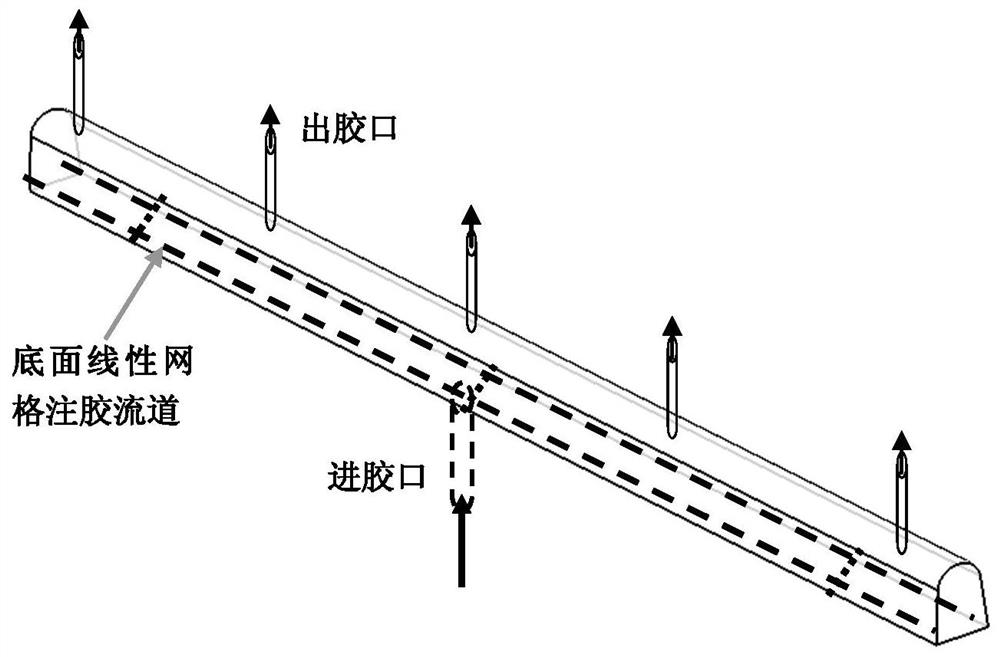

[0062] Make a 2.5D fabric reinforced leading edge structure 1500mm long with a section height of 80mm and a width of 65mm.

[0063] Concrete preparation process is as follows:

[0064] 1. Design the injection channel

[0065] Such as image 3 , 4 As shown, the thickness direction of the three-dimensional fabric is the glue injection direction, and a linear grid-like flow channel connected to it is set at the glue injection port, and the glue outlet is evenly designed on the non-working surface of the three-dimensional fabric.

[0066] 2. Design the curing process, such as Figure 6 shown.

[0067] 3. Weave the three-dimensional fabric and trim the shape.

[0068] 4. The three-dimensional fabric is loaded into the RTM mold

[0069] Put the trimmed fabric into the RTM mold, the thickness direction of the mold is the glue injection direction, and a glue injection port and a linear grid-shaped flow channel connected to it are set at the bottom of the mold (such as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com