Portable food container

A food container and portable technology, applied in the field of portable food containers, can solve the problems of wear, overload of the locking body, deformation, etc., and achieve the effect of small material wear and good positionability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

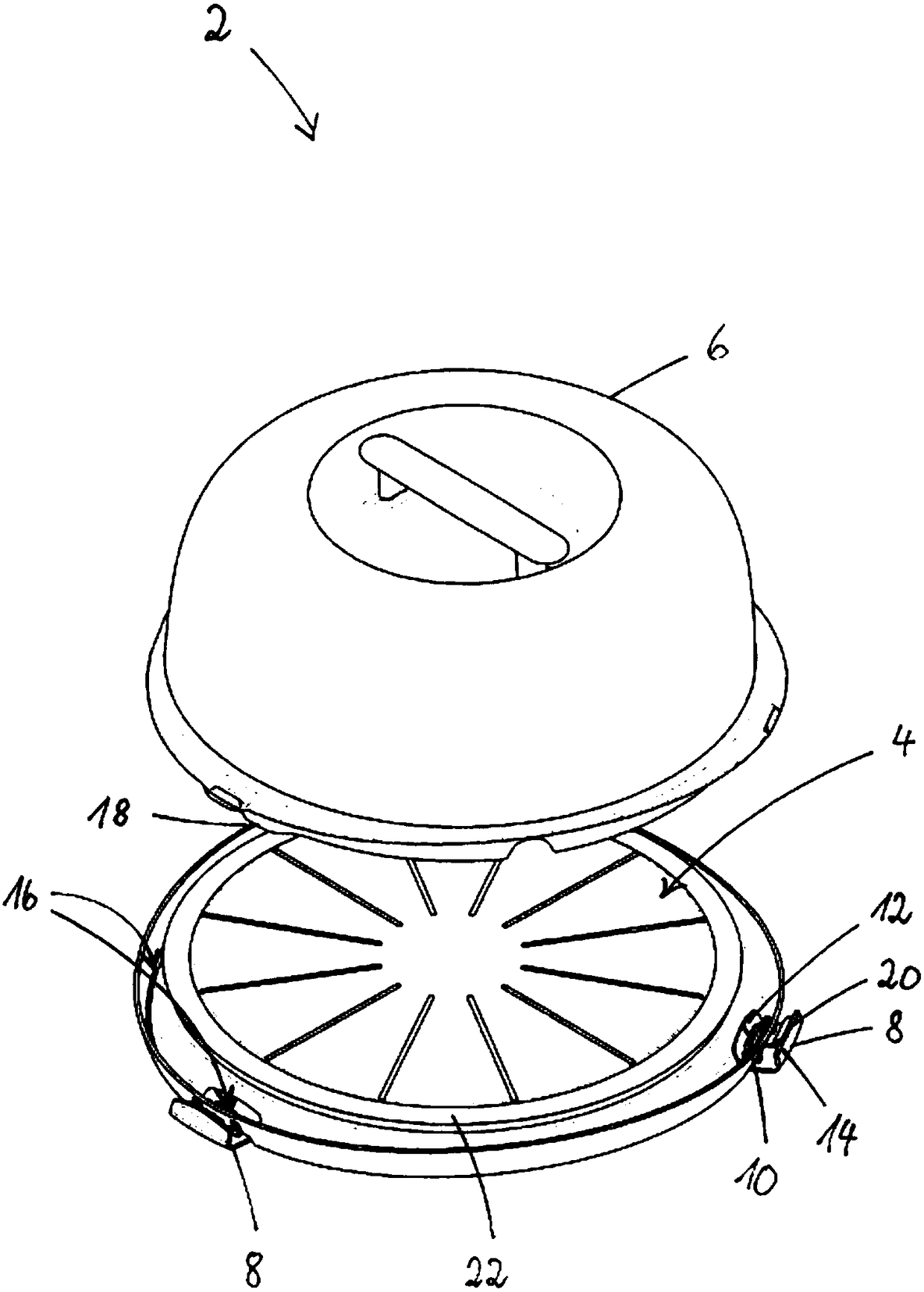

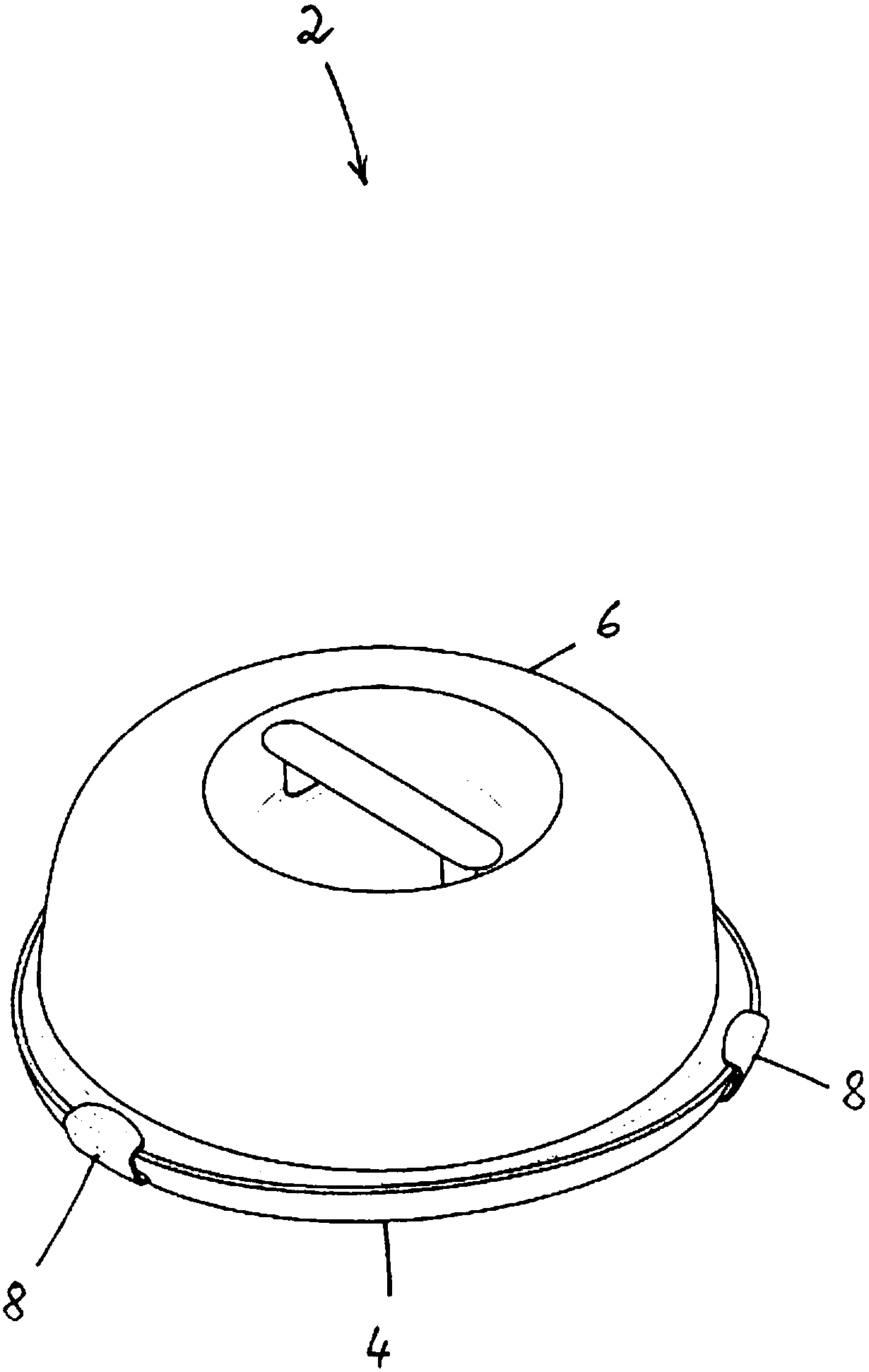

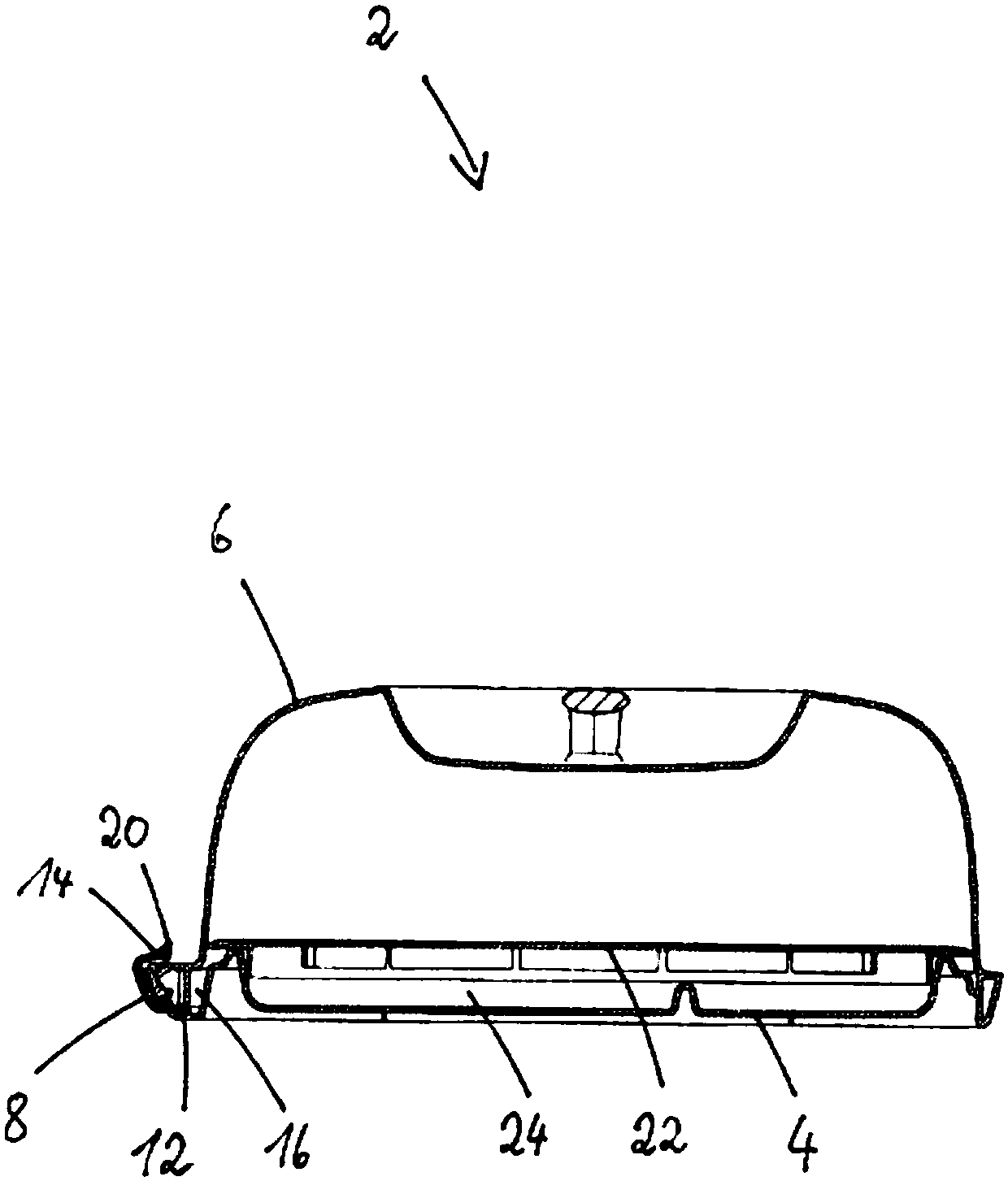

[0027] exist figure 1 A food container 2 is shown in FIG. 2 , which may substantially consist of a base part 4 and a cover 6 which may be placed thereon. In order to prevent the cover 6 from being unintentionally released during transport, the bottom part 4 and the cover 6 can be locked to one another via a locking element 8 . In secure locking, the food container 2 can likewise be carried on its handle in the cover 6 .

[0028] The locking element 8 can correspondingly be pivoted about the axis of rotation 10 . In order to pivot the locking element 8 , the cover 6 is lowered with the actuating flange 18 at the bottom-side edge of the cover 6 onto the corresponding actuating surface 12 at the first end of the locking element 8 . During further lowering of the cover 6 along the lowering path into the receiving chamber 16 , the corresponding actuating flange 18 presses the associated actuating surface 12 of the locking element 8 downward. By downward movement of the actuating...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap