Vibration bottom plate of electric iron

A soleplate and front soleplate technology, which is applied in the field of vibrating soleplates and electric irons, can solve problems such as large contact area of the soleplate, difficulty in pushing, and deformation, and achieve the effects of reducing fatigue, reducing driving force, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

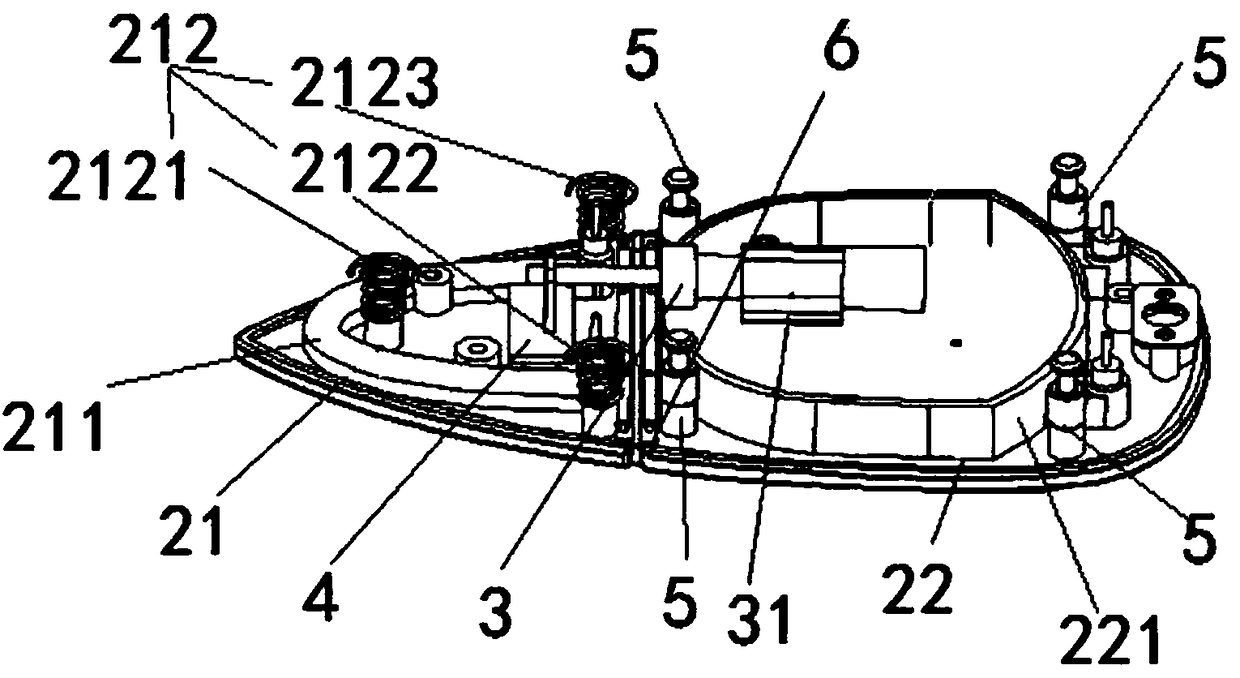

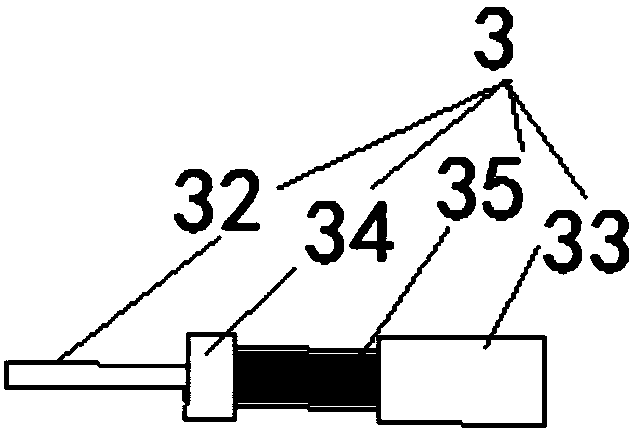

[0024] figure 1 It is a perspective view of a vibrating bottom plate of an electric iron of the present invention; figure 2 It is a schematic diagram of a vibrating motor of a vibrating bottom plate of an electric iron according to the present invention.

[0025] See Figure 1 to Figure 2 As shown, in a preferred embodiment, a vibrating soleplate of an electric iron, including:

[0026] Insulation shell 1.

[0027] Chassis 2, chassis 2 comprises front bottom plate 21 and rear bottom plate 22; The rear end of front bottom plate 21 connects the front end of rear bottom plate 22 through silica gel 6; The rear end of the thermal shell 1.

[0028] The vibration motor 3 is fixedly connected to the upper end surface of the rear bottom plate 22 through the motor pressure plate 31 .

[0029] The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Telescopic distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap