Capsule pressure-stabilizing tank

A pressure-stabilizing tank and bladder-type technology, applied in the field of water supply equipment, can solve the problems of high cost, high leakage risk of sealed air, and substandard environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

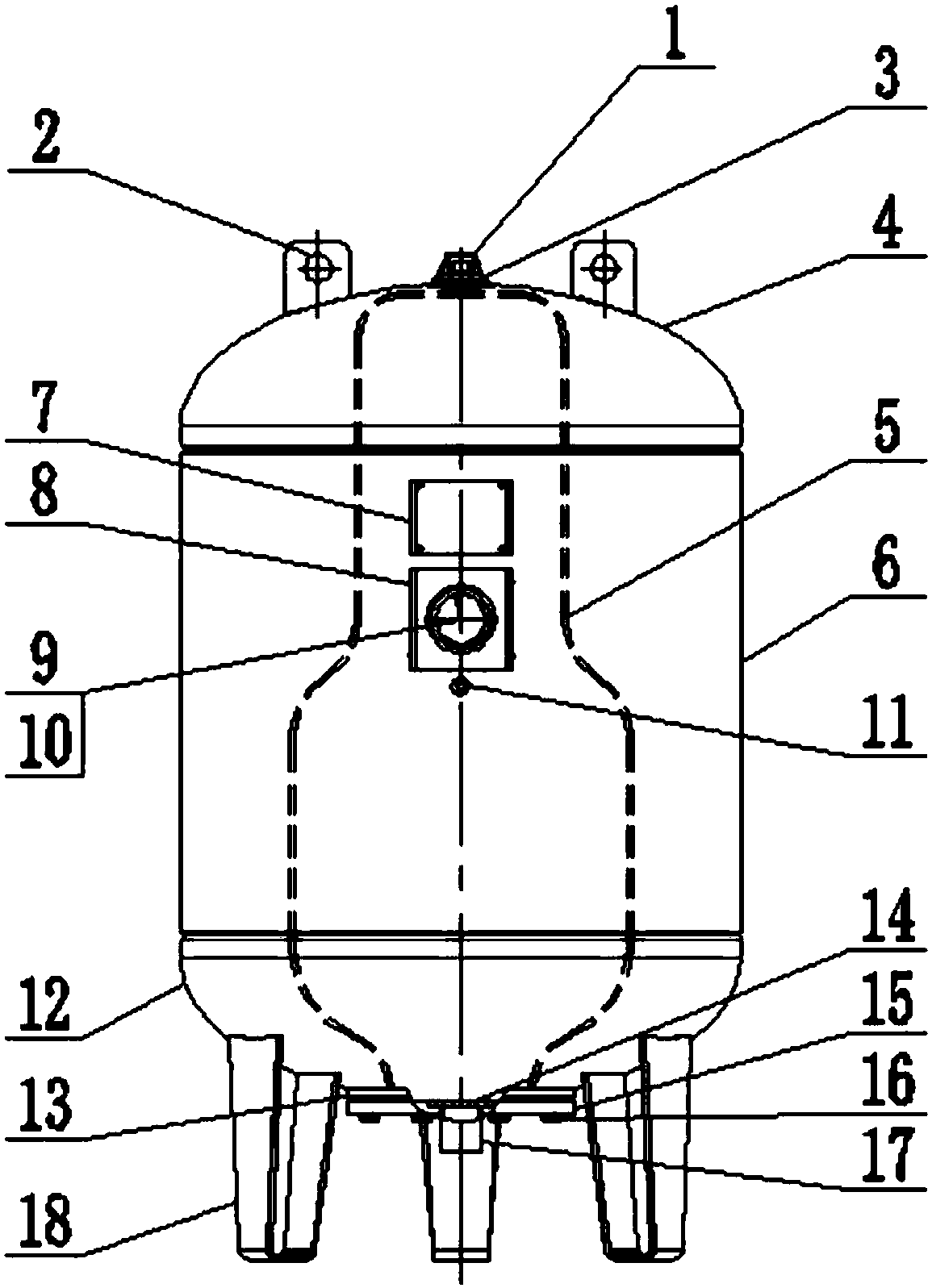

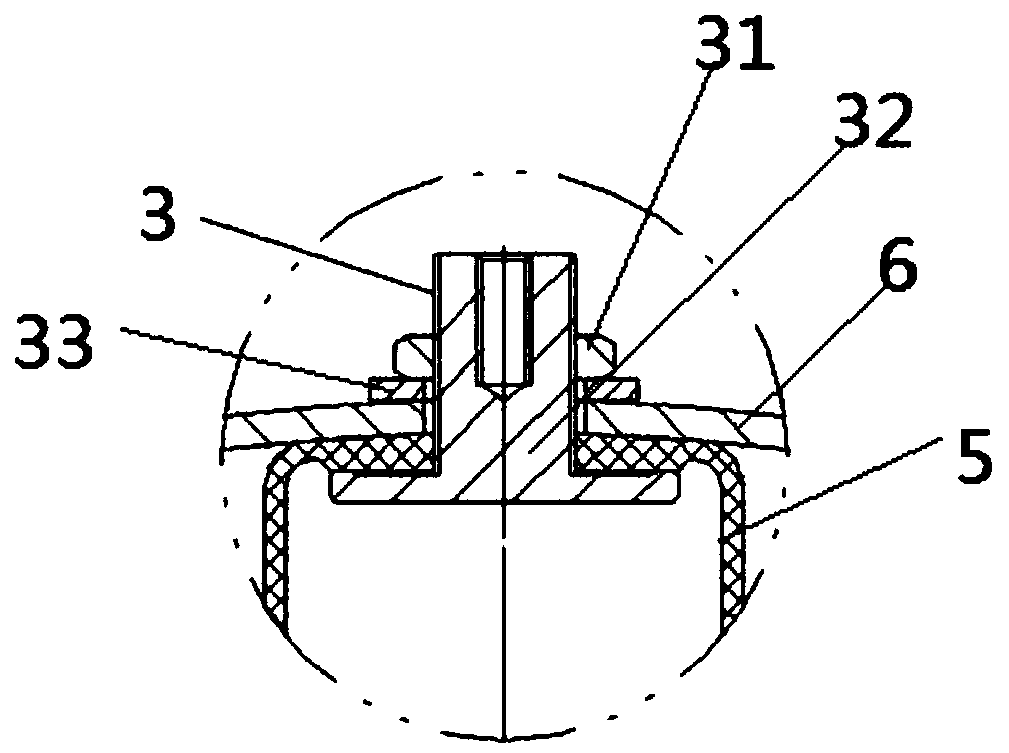

[0018] Such as figure 1 As shown, a bladder-type surge tank includes a tank body 6 and an inner bag 5 arranged in the tank body, the upper head 4 is welded on the top of the tank body, the lower head 12 is welded on the bottom, and the inner bag 5 isolates the tank body into gas. Chamber and water chamber, flange 13 is provided at the bottom of the tank body, and an inlet and outlet water connection pipe 17 communicating with the water chamber is arranged at the center of the bottom of the lower head 12, and the inlet and outlet water connection pipe 17 is welded and fixed with the flange plate 15. Three legs 18 are fixedly installed on the bottom of the lower head, and the three legs 18 are distributed symmetrically at the bottom of the tank body. The flange 15 is fixedly connected to the flange 13 through bolts 16 fastened on the circumference. A flat filter baffle 14 is also arranged between the flange 13 and the flange 15, and a plurality of through holes are evenly opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com