Stably connected torque sensor

A torque sensor, stable technology, applied in the field of torque sensor with stable connection, can solve problems such as loose joints of robots, affecting robot performance, etc., and achieve the effect of ensuring normal use, avoiding slippage, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

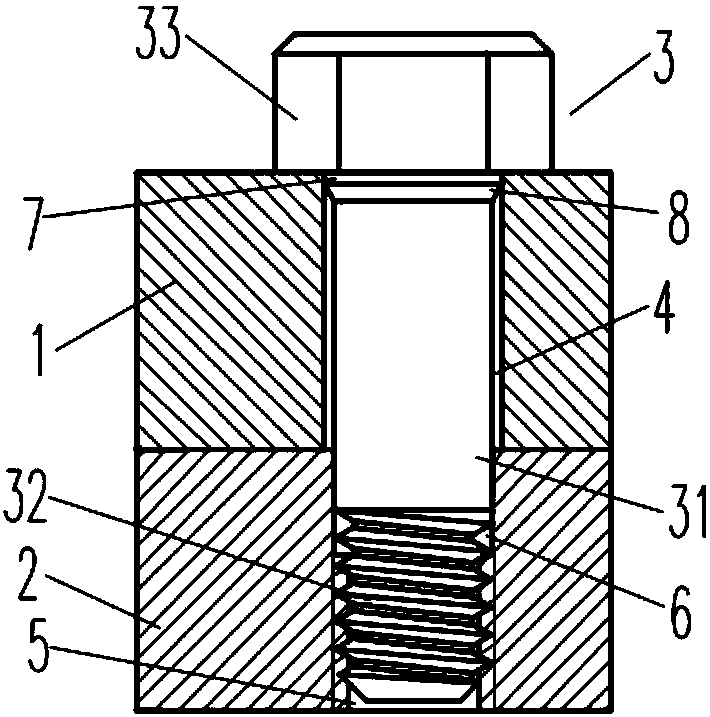

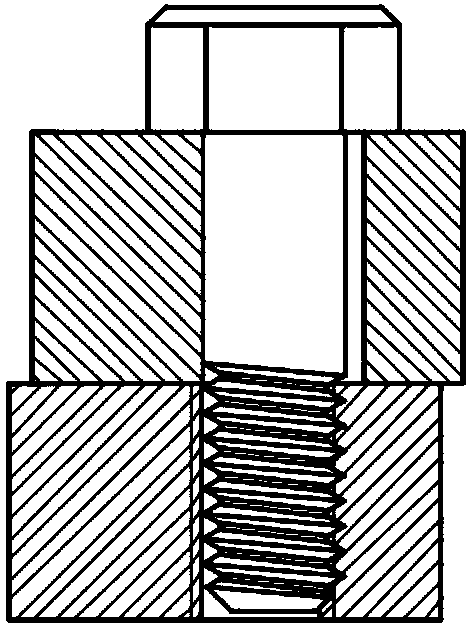

[0021] Please refer to figure 1 , the present invention provides a firmly connected torque sensor, including a torque sensor body 1, an external connection fixture 2 and a screw 3, the torque sensor body 1 is provided with a through hole 4, and the external connection fixture 2 is provided with a coaxial threaded hole 5 and Positioning hole 6, positioning hole 6 is positioned at the outer side of threaded hole 5, and the inner diameter of positioning hole 6 is equal to the nominal diameter of threaded hole 5; The rod portion of screw 3 includes the polished rod portion 31 that is positioned at rear end and the threaded portion 32 that is positioned at front end, and the threaded portion 32 is provided with an external thread that matches the internal thread of the threaded hole 5; the torque sensor body 1 and the external connection fixture 2 are firmly connected by the screw 3. When connecting, the threaded part 32 and the polished rod part 31 pass through the through hole 4, ...

Embodiment 2

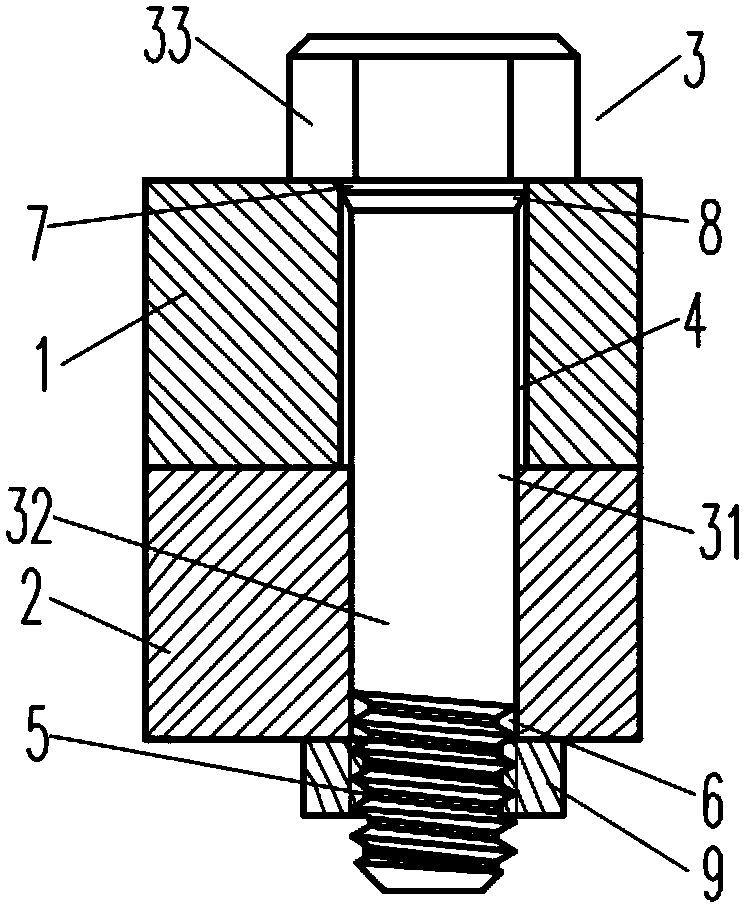

[0026] Please refer to image 3 , different from Embodiment 1, in this embodiment, the firmly connected torque sensor also includes a nut 9, at this time, the threaded hole 5 is replaced by the internal threaded hole of the nut 9, and the external connection fixture 2 is provided with a positioning hole 6, The positioning hole 6 passes through the entire external connection fixture 2. When connecting, the threaded part 32 and the polished rod part 31 pass through the through hole 4. The threaded part 32 is located in the internal threaded hole of the nut 9, and part of the polished rod part 31 is located in the positioning hole 6, that is, The connection between the torque sensor body 1 , the external connection fixture 2 , the screw 3 and the nut 9 is achieved through the action of the threaded portion 32 of the screw 3 and the internal threaded hole of the nut 9 .

Embodiment 3

[0028] Please refer to Figure 4 , different from Embodiment 1, in this embodiment, the torque sensor body 1 includes an inner ring 11 and an outer ring 12, and the external connection fixture 2 includes an inner ring connection fixture 21 and an outer ring connection fixture 22; A coaxial threaded hole 5 and a positioning hole 6 are provided. The inner ring connecting jig 21 is provided with a through hole 4. The inner ring 11 and the inner ring connecting jig 21 are firmly connected by screws 3. When connecting, the threaded part 32 and the polished rod part 31 Through the through hole 4, the threaded part 32 is located in the threaded hole 5, and part of the polished rod part 31 is located in the positioning hole 6; the outer ring 12 is provided with a through hole 4, and the outer ring connecting fixture 22 is provided with a coaxial threaded hole 5 and positioning Hole 6, the outer ring 12 and the outer ring connection fixture 22 are firmly connected by screws 3. When con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com