A liquid level sensor and its outer pipe connection and fixing method

A technology of liquid level sensor and outer tube, which is applied to the liquid level indicator, liquid level indicator, liquid/fluid solid measurement of physical variable measurement, etc. Sensor security and reliability issues to achieve the effect of a solid connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

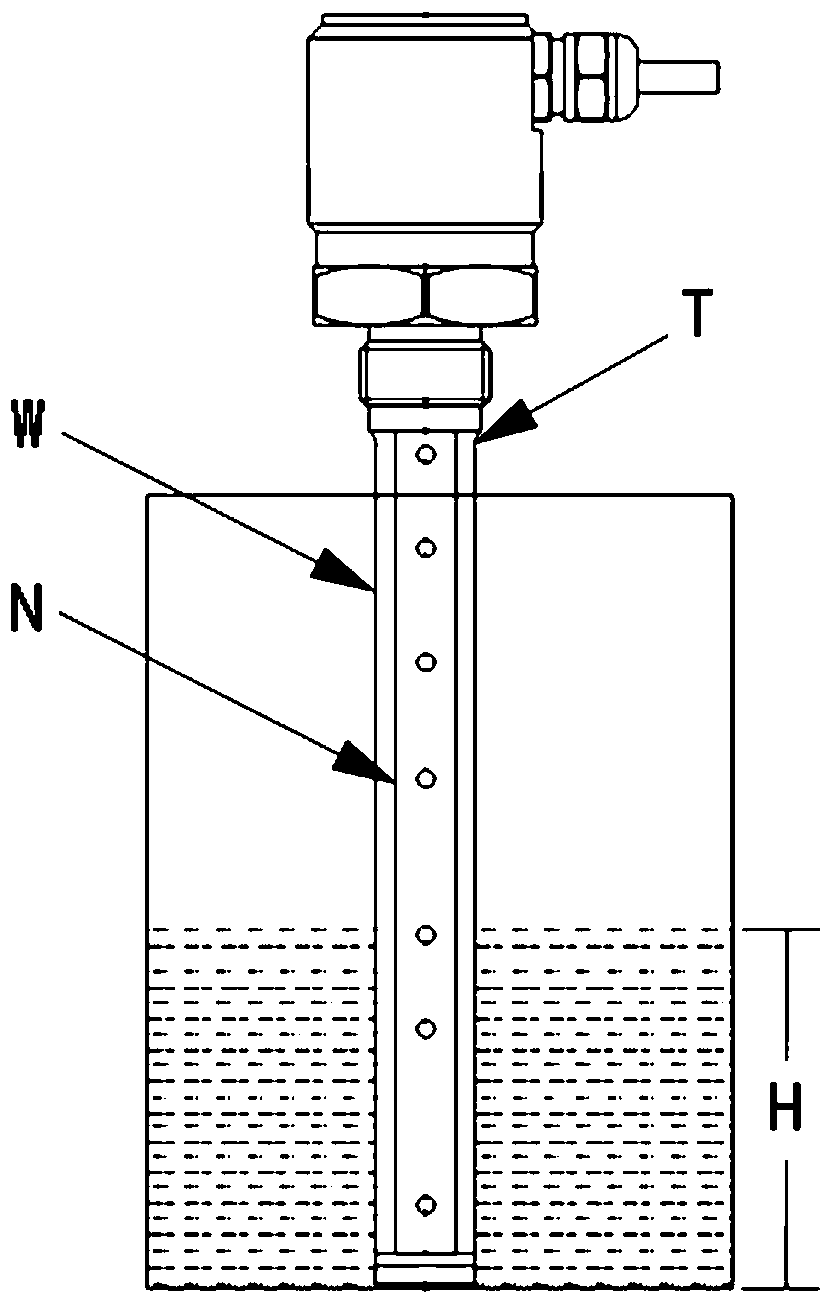

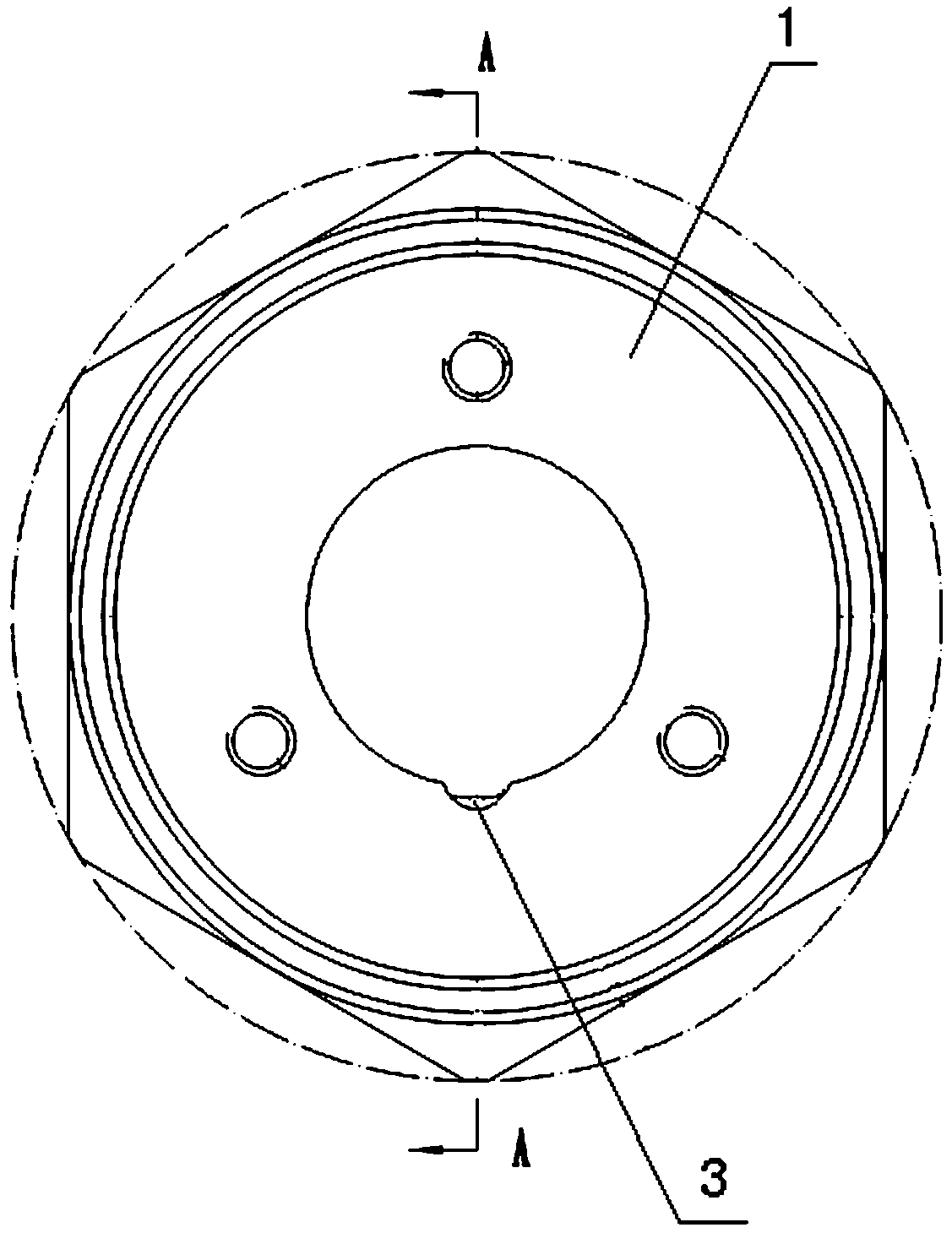

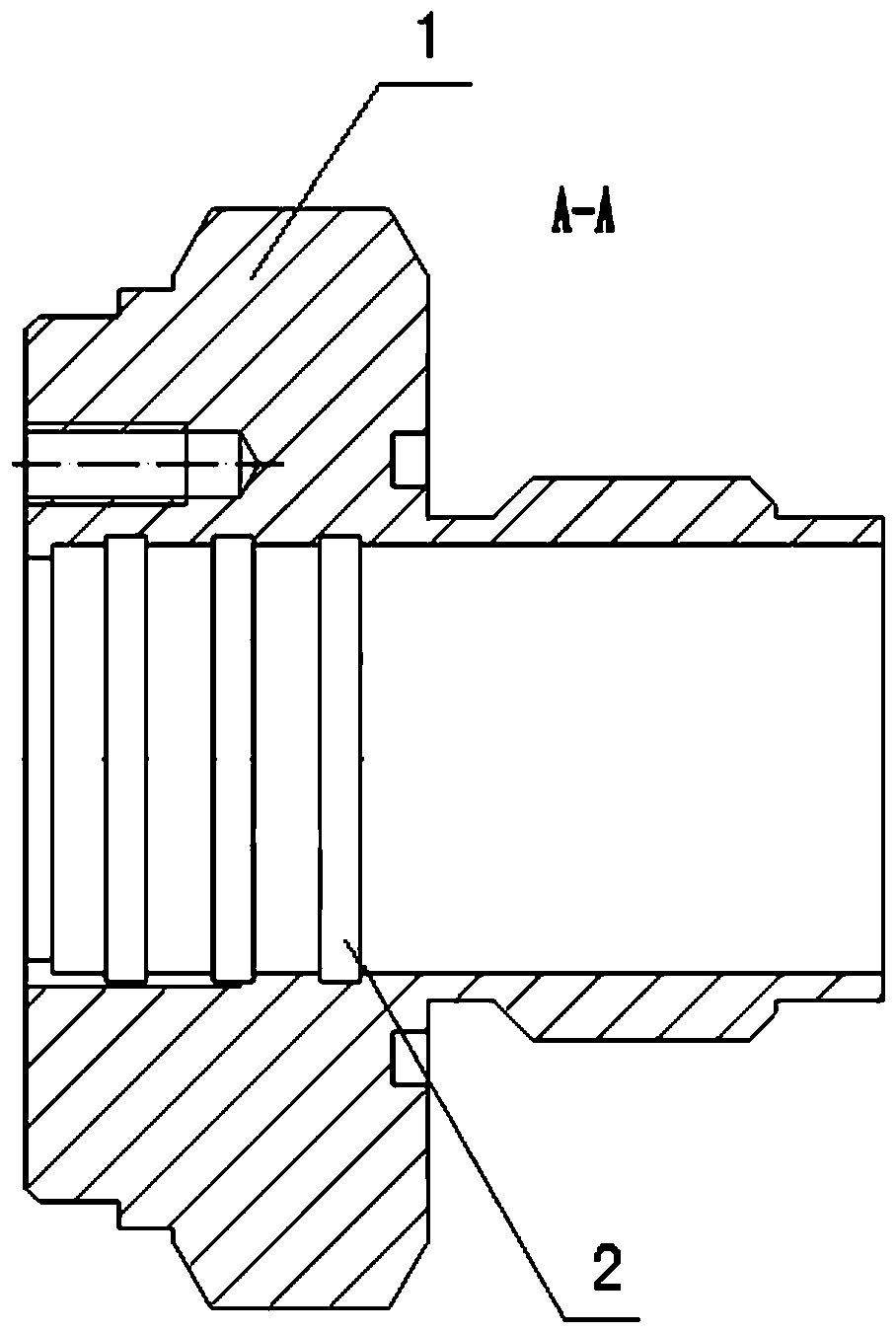

[0023] refer to figure 2 , image 3 with Figure 4 , a liquid level sensor, including a threaded joint 1 and an outer tube W used as an external electrode, the outer wall of the upper end of the threaded joint is provided with threads (not shown in the figure), and the upper end of the outer tube W extends into the inner cavity of the threaded joint 1 Among them, the outer diameter of the outer tube W is adapted to the diameter of the inner cavity of the threaded joint 1, and a fastening connection structure is provided between the outer wall of the upper end of the outer tube W and the inner wall of the inner cavity of the threaded joint 1, so as to realize the firmness of the outer tube and the threaded joint connect.

[0024] The fastening connection structure includes a card groove 2 and an outer tube locking notch 3 arranged on the inner wall of the threaded joint cavity, the outer tube W is an aluminum alloy outer tube that can be deformed by extrusion, and the alumin...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is:

[0032] The outer wall of the upper end of the outer tube W is directly welded to the inner wall of the inner cavity of the threaded joint 1 to achieve a firm connection between the outer tube W and the threaded joint 1 .

[0033] The method of connecting and fixing the outer pipe of the liquid level sensor in this embodiment is as follows:

[0034] After the upper end of the aluminum alloy outer tube is inserted into the inner cavity of the threaded joint 1, the outer wall of the upper end of the outer tube W is directly welded to the inner wall of the inner cavity of the threaded joint 1 by means of laser or argon arc welding. Below the threaded opening (not shown in the figure) of the joint 1, so as to facilitate the further assembly of other component structures of the liquid level sensor.

[0035] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com