Motor fixing support and assembling method thereof

A technology for motor fixing and installation slots, which is applied in the direction of electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve problems such as falling off, complicated operation, and increased additional costs, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

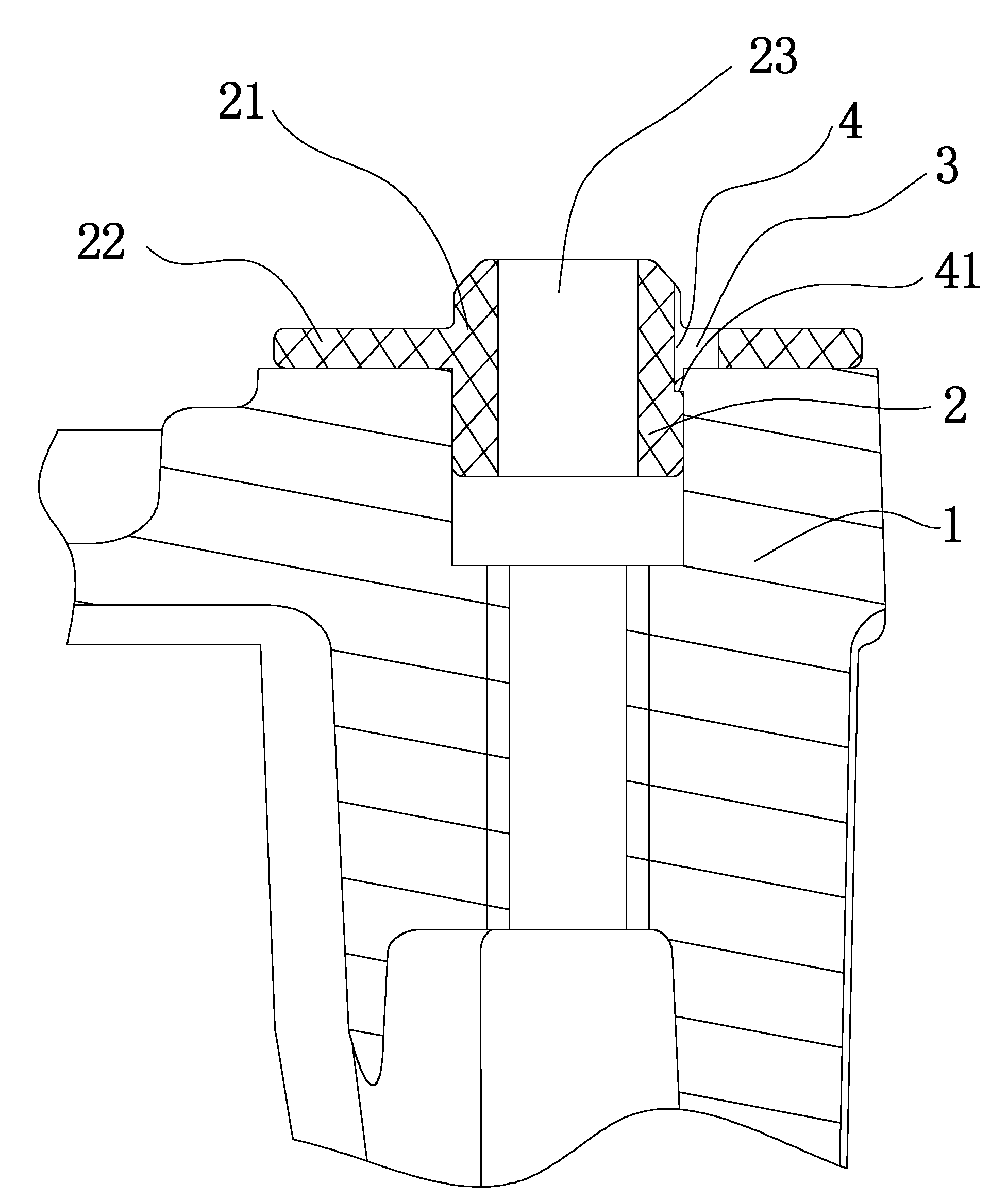

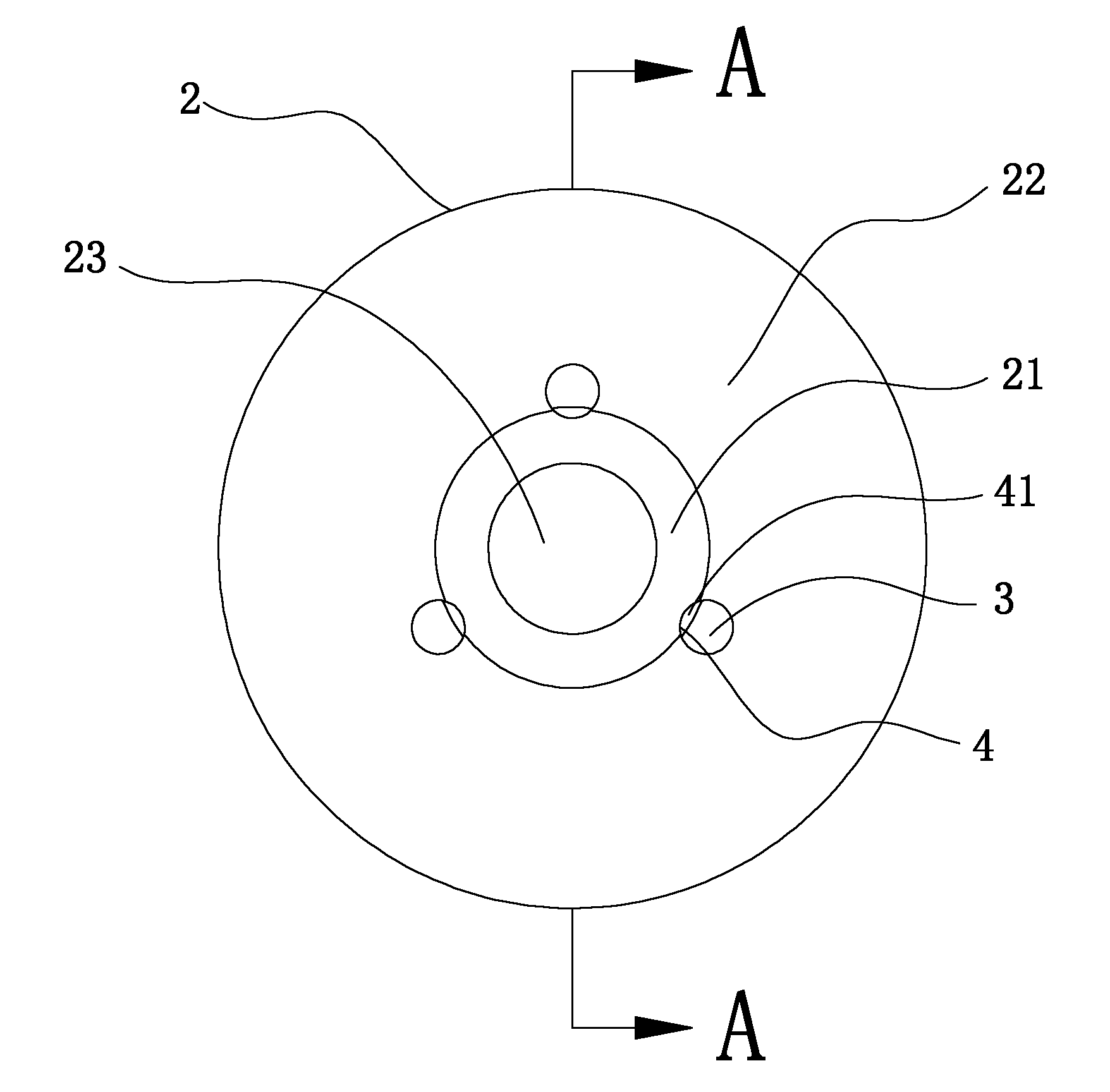

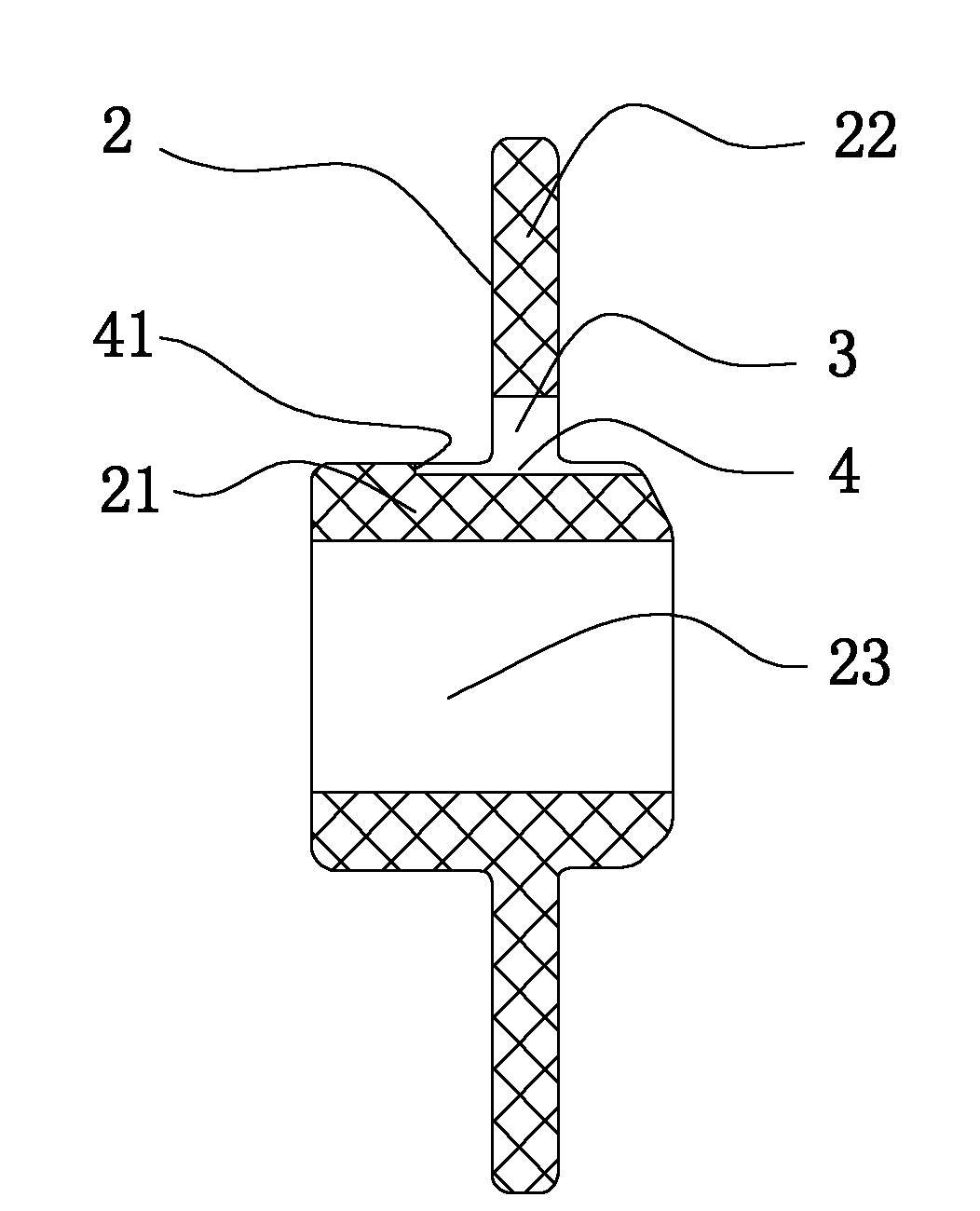

[0015] like Figure 1-Figure 4 The shown motor fixing bracket includes an end cover 1 and insulating mesons 2 installed on the surface of the end cover 1 . The material of the end cap 1 is non-ferrous metal, which may be aluminum alloy or iron; the material of the insulating meson 2 is plastic or nylon or rubber. The insulating meson 2 includes a main body 21 and a baffle 22 sleeved on the peripheral surface of the main body 21 , the baffle 22 is arranged in the middle of the main body 21 and has an integrated structure with the main body 21 .

[0016] like Figure 4 As shown, there are several installation grooves 11 on the surface of the end cover 1. The preferred embodiment of this case is to set four installation grooves 11 and be located at the edge of the end cover 1. Of course, the present invention is not limited to a definite number of installation grooves. Can be set according to needs. like figure 1 As shown, the body 21 corresponds to the shape and size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com