Trackside equipment mounting structure suitable for U-shaped beam

A technology of trackside equipment and installation structure, which is applied in bridge construction, noise absorbing devices, bridges, etc., and can solve problems such as the inability to locate the beam body and reserve the installation foundation, the contradiction between sound barriers and trackside equipment installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the typical embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

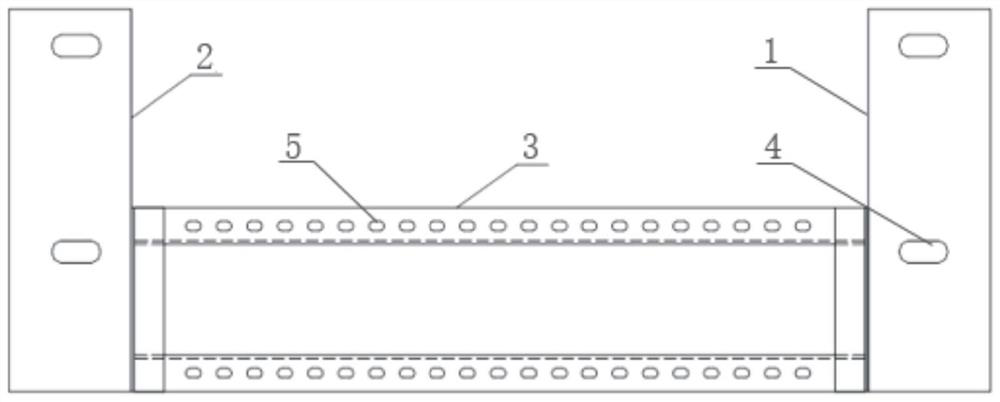

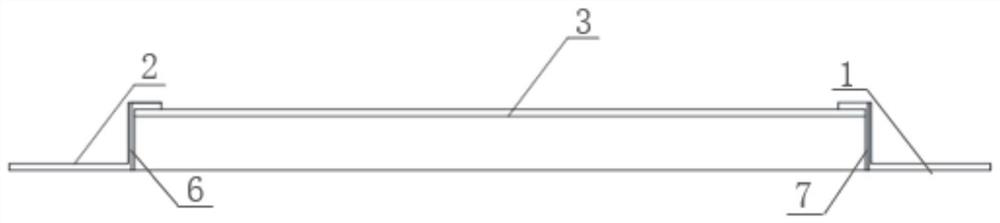

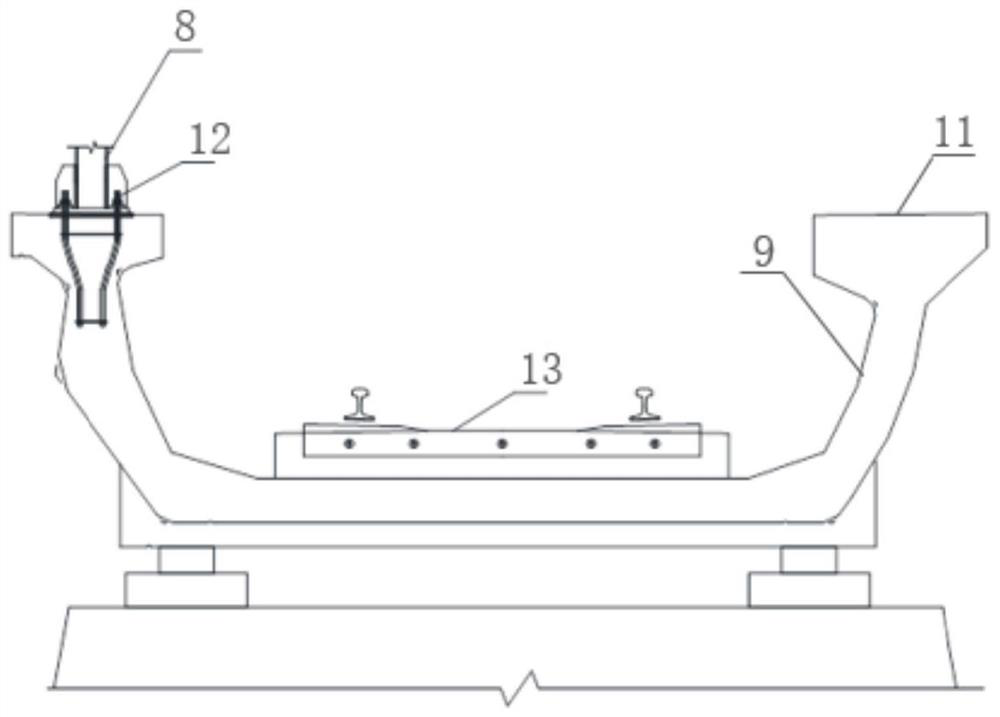

[0027] The cross-sectional structure of the U-shaped beam is as follows: image 3 As shown, the inner bottom of the U-shaped beam is provided with a ballast bed 13, which has two U-shaped beam wings 9, and a sound barrier embedded part 12 is provided on the top surface 11 of the U-shaped beam side wing. The sound barrier embedded part 12 is usually a A group of bolts, the sound barrier H-shaped steel column 8 is connected with the U-shaped beam by bolts.

[0028] like Figure 4 As shown, the sound barrier 10 is installed on the sound barrier H-shaped steel column 8, and the sound barrier embedded parts 12 are arranged at a set distance, which is determined according to the length of the sound barrier installed.

[0029] Normally, trackside equipment is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com