Multi-channel chain tight joint and missing part detection machine

A multi-channel, detection machine technology, applied in geophysical measurement, instruments, etc., can solve problems such as lack of rollers, low detection sensitivity of sleeves, high cost of visual detection, wear of contact pieces, etc., to achieve compact structure and low production cost. Low, precise display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the present invention will be described in detail below in conjunction with the preferred embodiments of the present invention given in the accompanying drawings.

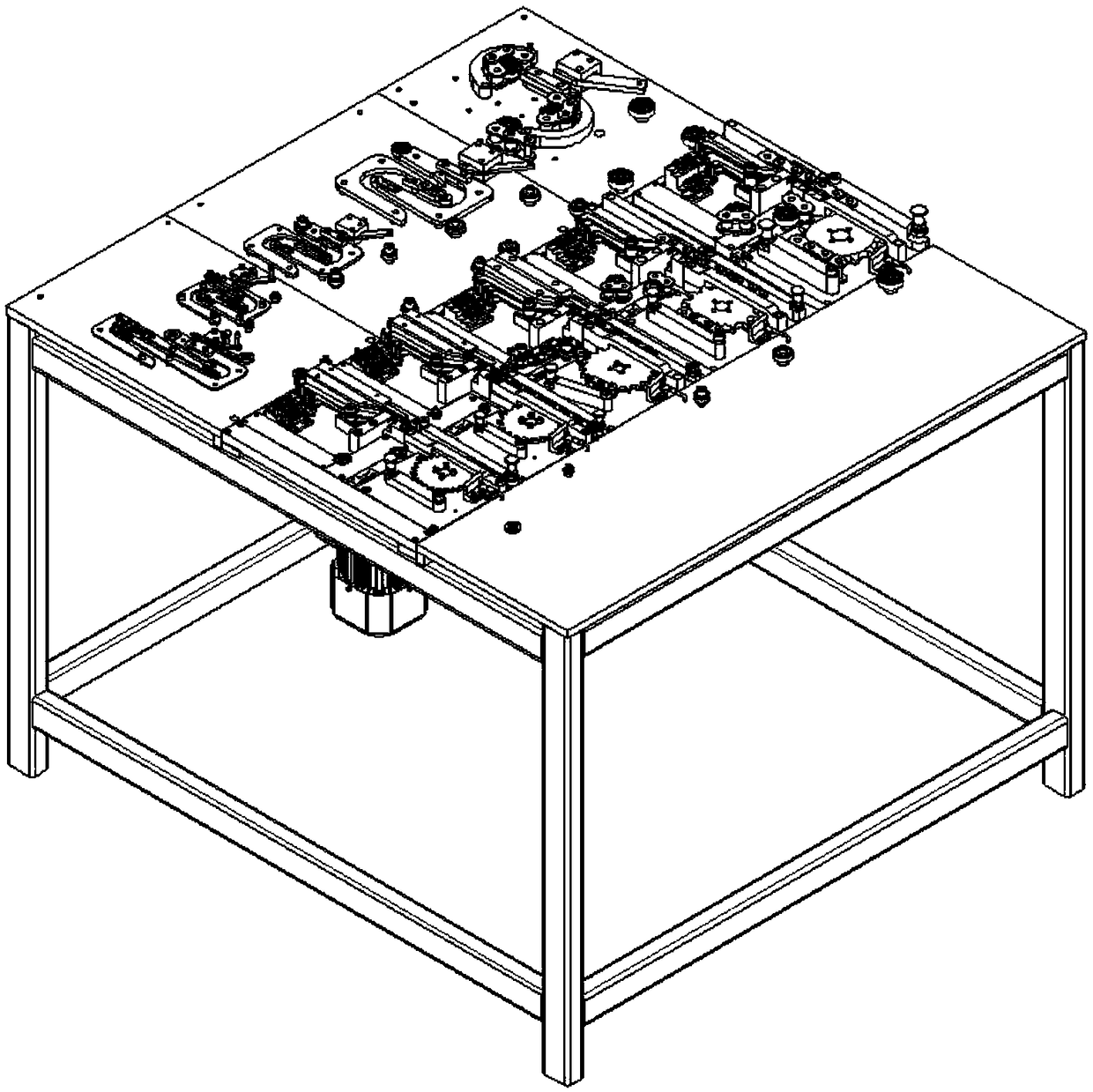

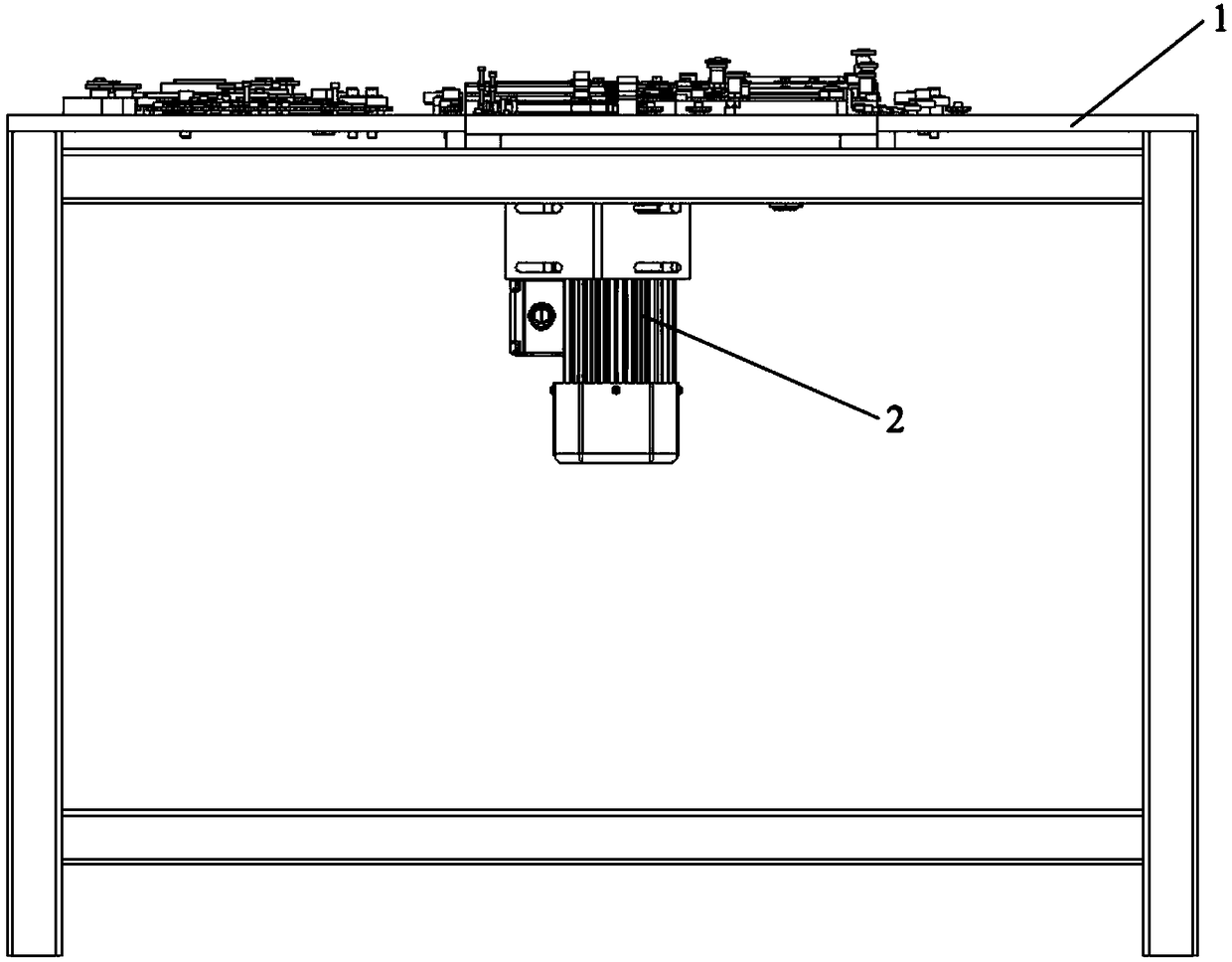

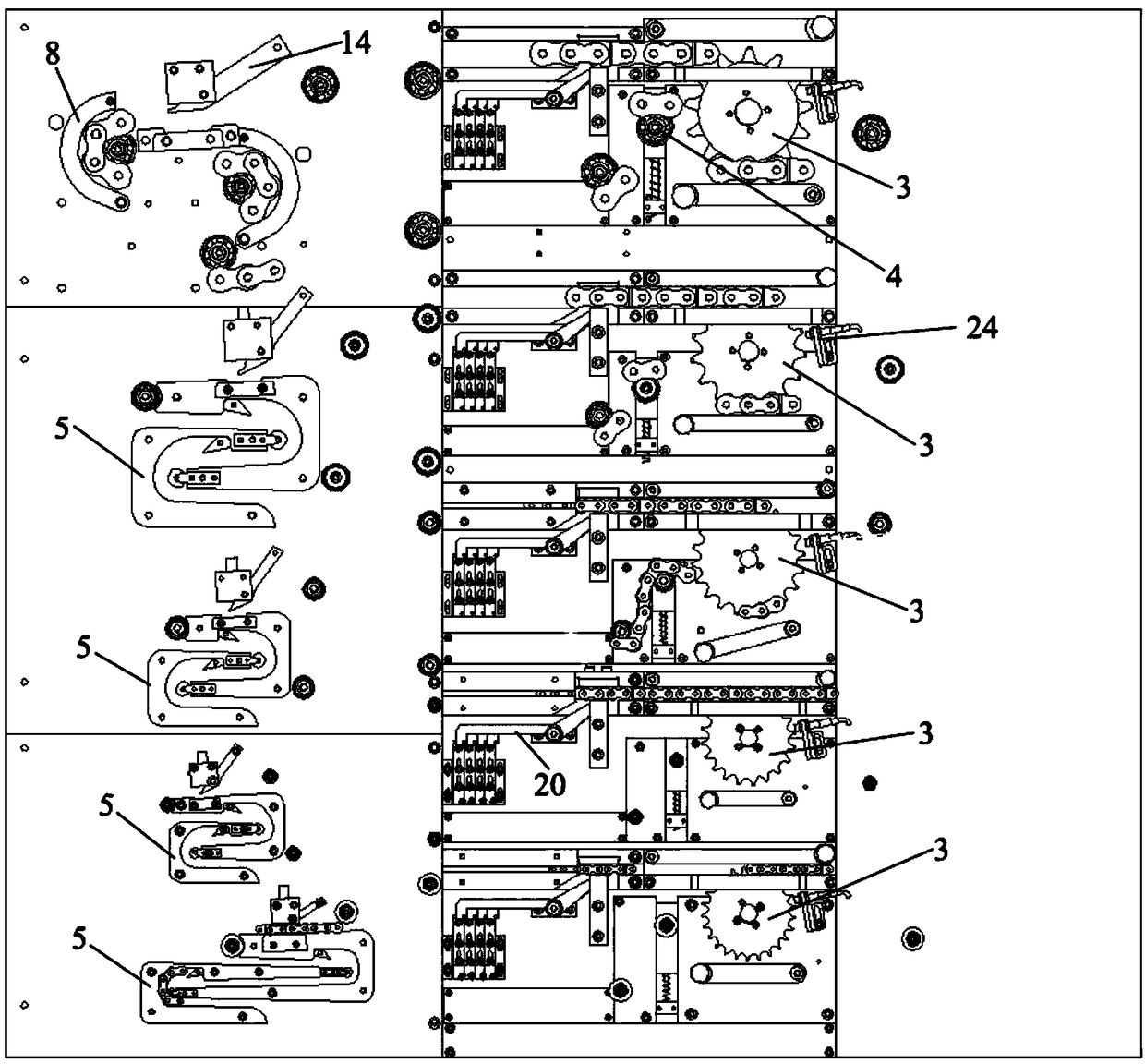

[0026] Such as Figures 1 to 4 As shown, the multi-channel chain tight joint and missing part detection machine of the embodiment of the present invention includes a detection table 1, a drive motor 2 and a PLC control system, and several pieces of different specifications are arranged side by side on the table of the detection table 1. In this embodiment, five detection channels are integrated for detecting chains of five specifications, 40 / 50 / 60 / 80 / 100, with compact structure and unified control. Each of the detection channels is correspondingly arranged with a drag sprocket 3 for driving the chain to be inspected, a tight joint detection mechanism, a missing roller sleeve detection mechanism and a missing chain piece detection mechanism, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com