Ship exhaust gas denitrification function simulation system

A simulation system and function simulation technology, applied in the field of ships, can solve the problems of inconvenient system debugging, inconvenient operation training, time-consuming, labor-intensive and oil-consuming, etc., to improve the training effect, improve the solution ability, and reduce the training cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

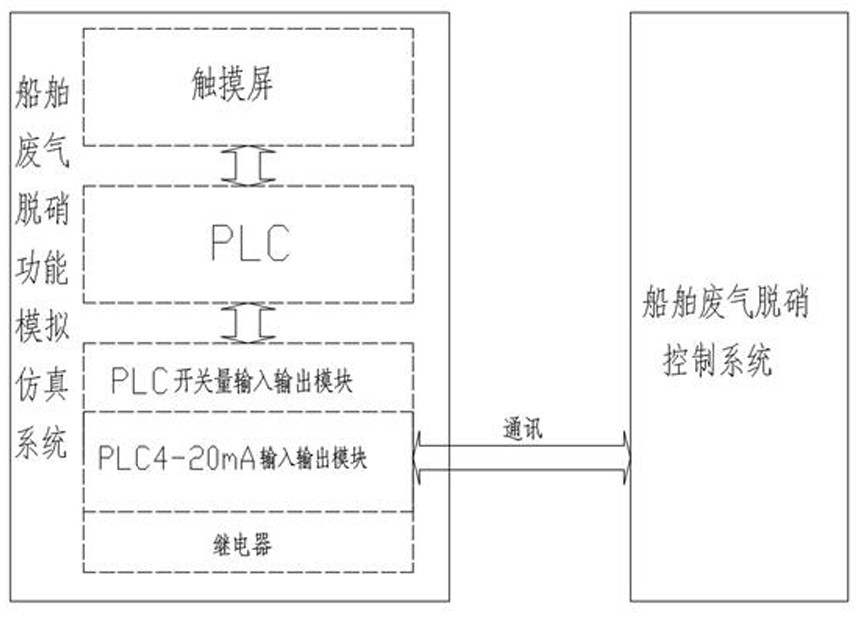

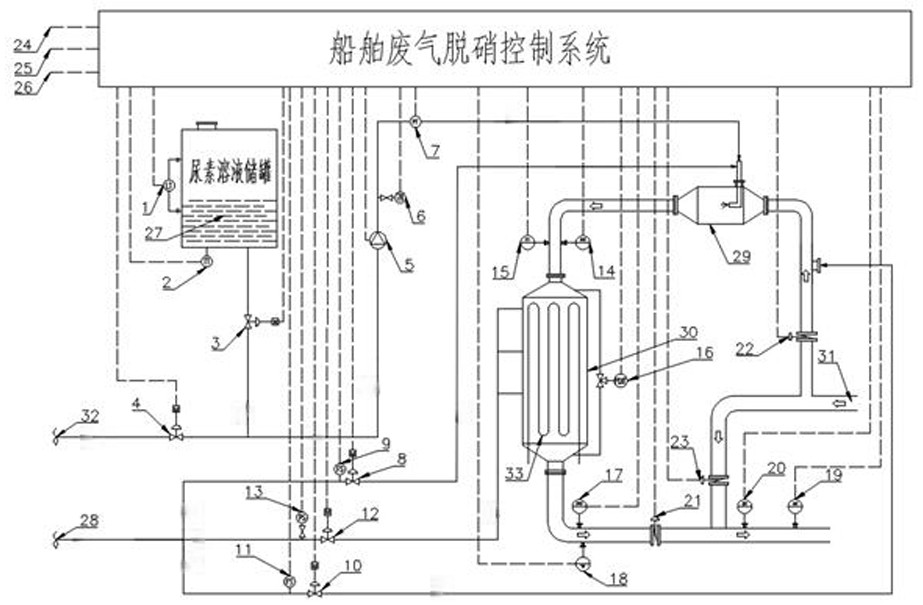

[0014] see figure 1 and figure 2 , a kind of ship exhaust gas denitrification function simulation system of the present invention is characterized in that, comprises touch screen, PLC, relay, button switch and indicator light, uses the switch quantity input and output module of PLC, relay, and the 4-20mA input and output module of PLC Simulate the hardware signals of ship exhaust gas denitrification equipment, and use PLC software programming to realize the logical relationship between various hardware signals; design corresponding simulation control output signals for different ship exhaust gas denitrification equipment;

[0015] The simulated ship exhaust gas denitrification equipment includes: urea storage tank level gauge 1, urea storage tank temperature sensor 2, urea storage tank outlet valve 3, flushing valve 4, urea addition pump 5, urea pipeline pressure sensor 6, urea pipeline Flow sensor 7, urea spray gun compressed air valve 8, urea spray gun compressed air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com