Automatic vehicle-mounted camera glue dispensing jig

A technology of automatic glue dispensing and camera, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of dispensing points at the same position, glue flow, dispensing failure, etc., and achieve precision improvement and dispensing. The effect of improving uniformity and relieving work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

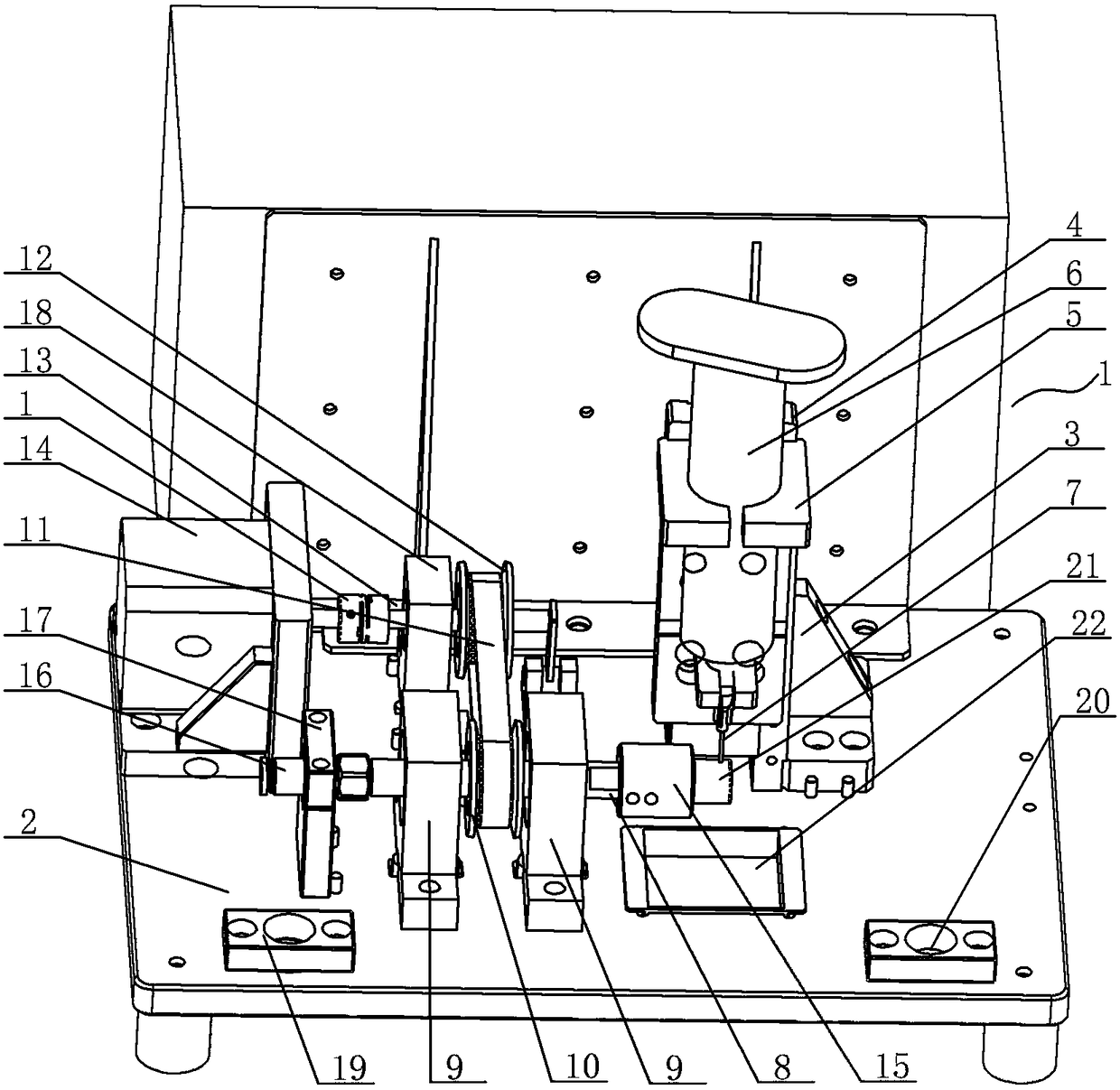

[0015] Vehicle camera automatic dispensing fixture, see figure 1 : It includes a mounting frame 1, a vertical mounting bracket 3 is arranged on the working surface 2 of the mounting frame 1, a dispensing cylinder 4 is fixed on the vertical surface of the vertical mounting bracket 3, and the output end 5 of the dispensing cylinder 4 is clamped with The dispensing tube 6 arranged vertically, the dispensing needle 7 is arranged under the dispensing tube 6, and the horizontal metal air pipe 8 is also arranged on the work surface 2, the middle part of the metal air pipe 8 is supported by the mounting frame 9 on both sides through the bearing, and the metal air pipe 8. An output pulley 10 is set between the mounting brackets 9 on both sides. The output pulley 10 is externally connected to the input pulley 12 through the timing belt 11. The input pulley 12 is set on the transmission shaft 13. The transmission shaft 13 is externally connected to the output of the motor 14. The end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com