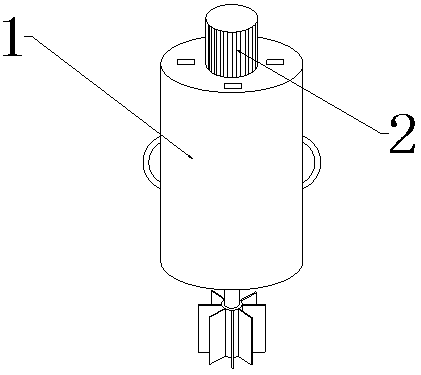

Anti-blocking charging equipment for blasting

An anti-clogging and charging technology, applied in blasting and other directions, can solve the problems of affecting blasting effect, deformation, destruction, loosening and throwing, without cleaning dust or foreign objects, etc., to achieve the effect of improving the stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

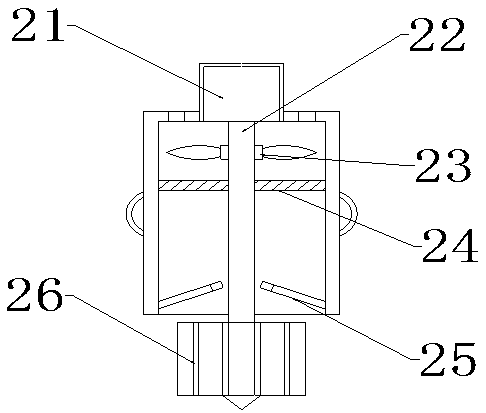

[0020] Specific implementation method: when in use, the user first turns on the motor 21, the motor 21 works to drive the rotating shaft 22 to rotate counterclockwise, the rotating shaft 22 rotates counterclockwise to drive the fan 23 and the stirring column 26 to rotate counterclockwise, and the fan 23 rotates counterclockwise to generate upward suction. Then the baffle 25 rotates upward around the hinge under the upward suction force of the fan 23, and then the user holds the arc-shaped handle on the annular side of the hollow cylinder 1 and moves downward along the blast hole to be cleaned, and the downward movement of the hollow cylinder 1 drives The motor 21 moves downward, and the motor 21 moves downward to drive the rotating shaft 22 to move downward. The rotating shaft 22 moves downward to drive the stirring column 26 to move downward. 23 Under the action of upward suction, the dust is sucked into the hollow cylinder 1, and then the filter screen 24 filters the dust and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com