Online cleaning basket filter for high-concentration formaldehyde pipeline in production technology of trioxymethylene

A basket filter, high-concentration formaldehyde technology, applied in membrane filters, filtration separation, chemical instruments and methods, etc., can solve problems such as cavitation of transfer pumps, clogging of filter baskets, and heavy workload, and reduce mechanical failures efficiency, avoid cavitation, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

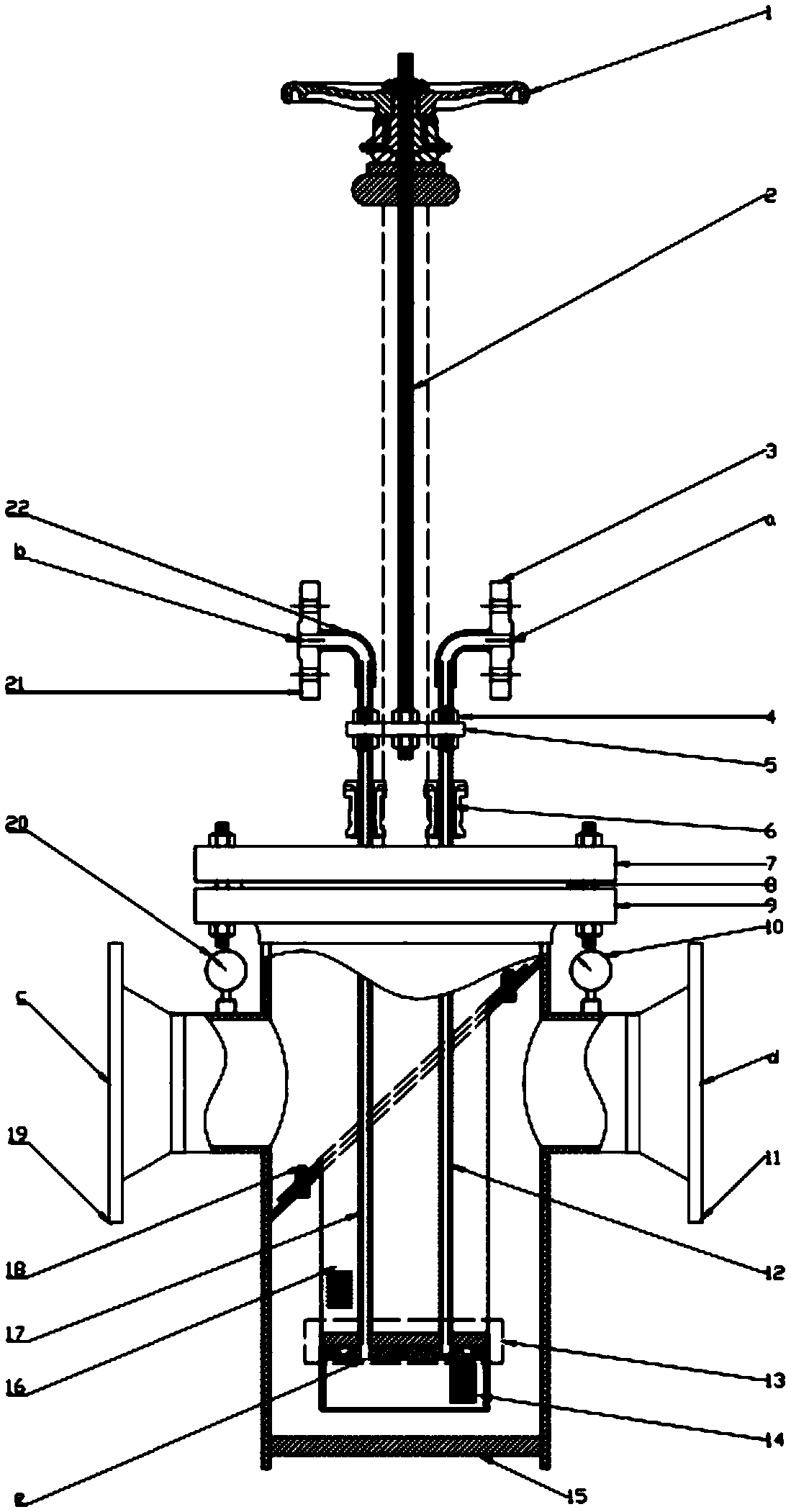

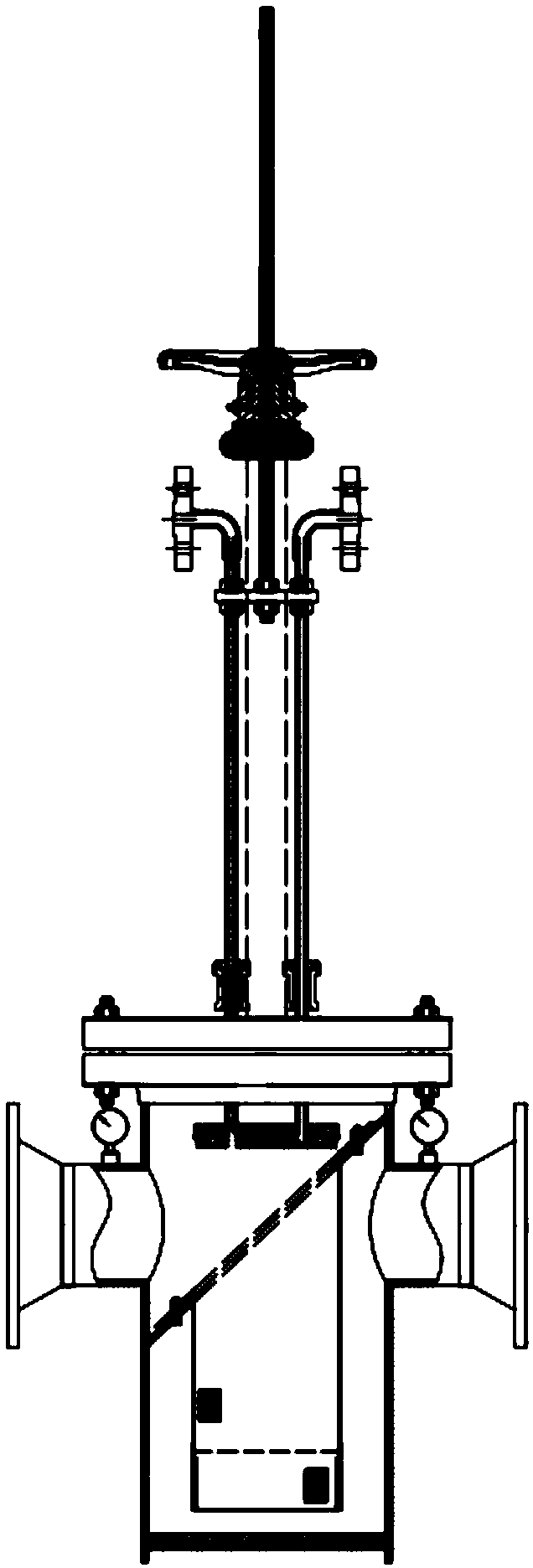

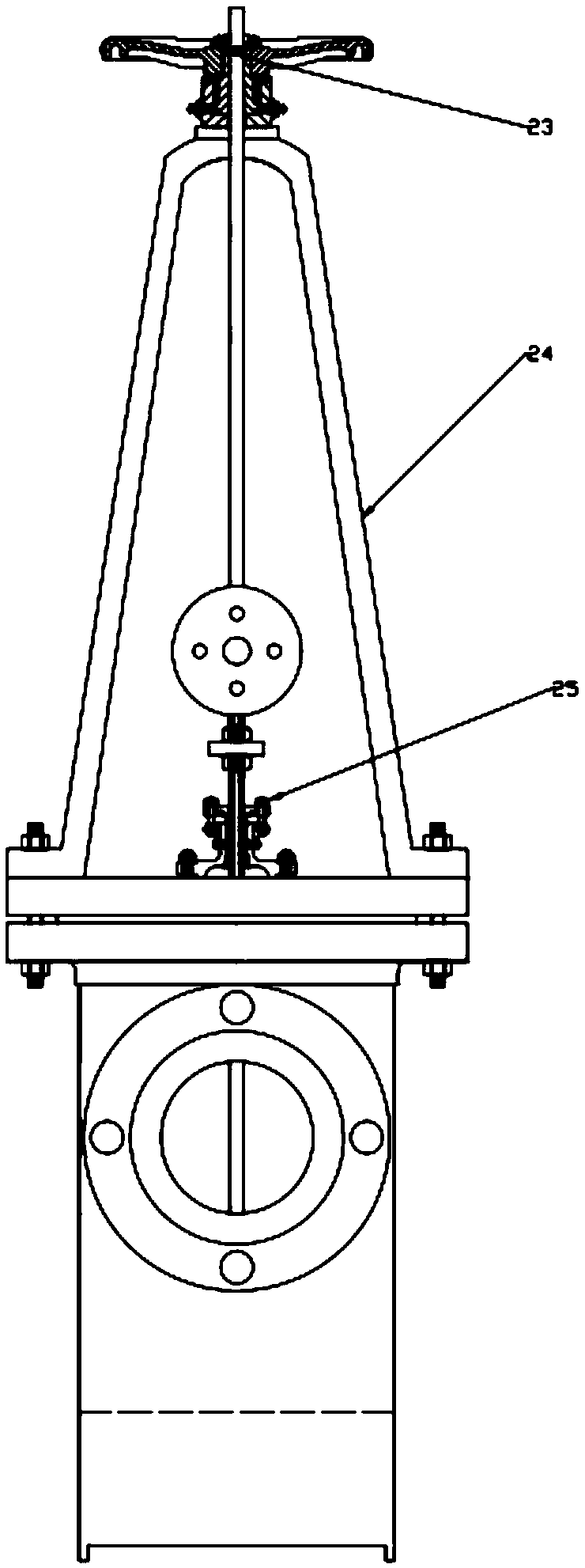

[0089] Such as Figure 1~5-2 As shown, an on-line cleaning basket filter for high-concentration formaldehyde pipelines in the production process of paraformaldehyde, including: hand wheel 1, transmission rod 2, cleaning water inlet flange 3, adjustment and fastening bolts 4, transmission force distribution plate 5 , sealing packing 6, filter sealing cover 7, sealing gasket 8, sealing flange 9, outlet pressure detection gauge 10, high-concentration formaldehyde outlet flange 11, hollow cleaning support rod Ⅰ (12), scraping jet cleaner 13. Sealed clean room 14, filter cylinder 15, filter basket 16, hollow cleaning support rod II (17), filter basket fixing bolt 18, high-concentration formaldehyde inlet flange 19, inlet pressure test gauge 20, sewage outlet method Lan 21, internal thread detachable elbow 22, transmission rod mark 23, power support 24, packing gland 25, positioning support piece 26, filter basket wall 27, sealed clean room wall 28, high-efficiency scraper piece 29,...

Embodiment 2

[0101] An on-line cleaning basket filter for high-concentration formaldehyde pipelines in a paraformaldehyde production process, comprising: a basket filter body, a scraping jet cleaner 13, hollow cleaning support rods I (12), II (17), Hand wheel 1, transmission rod 2, transmission force distribution plate 5, power support 24; the upper opening end of the basket filter body is provided with a sealing cover 7, and the hollow cleaning support rods I (12), II (17) Respectively vertically pass through the sealing cover 7 and connect to the scraping type jet cleaner 13, the top ends of the hollow cleaning support rods I (12), II (17) are located on the upper part of the sealing cover 7, and pass through the transmission force distribution plate 5 respectively It is connected with the lower end of the transmission rod 2 , and the upper end of the transmission rod 2 is connected with the hand wheel 1 , the hand wheel 1 is arranged on the power support 24 , and the power support 24 is ...

Embodiment 3

[0103] An on-line cleaning basket filter for high-concentration formaldehyde pipelines in a paraformaldehyde production process, comprising: a basket filter body, a scraping jet cleaner 13, hollow cleaning support rods I (12), II (17), Hand wheel 1, transmission rod 2, transmission force distribution plate 5, power support 24; the upper opening end of the basket filter body is provided with a sealing cover 7, and the hollow cleaning support rods I (12), II (17) Respectively vertically pass through the sealing cover 7 and connect to the scraping type jet cleaner 13, the top ends of the hollow cleaning support rods I (12), II (17) are located on the upper part of the sealing cover 7, and pass through the transmission force distribution plate 5 respectively It is connected with the lower end of the transmission rod 2 , and the upper end of the transmission rod 2 is connected with the hand wheel 1 , the hand wheel 1 is arranged on the power support 24 , and the power support 24 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com