Hollow large torque servo motor

A servo motor, high torque technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large space occupied and unreasonable structure layout of servo motors, and achieve compact structure, avoid messiness, and reduce magnetic leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

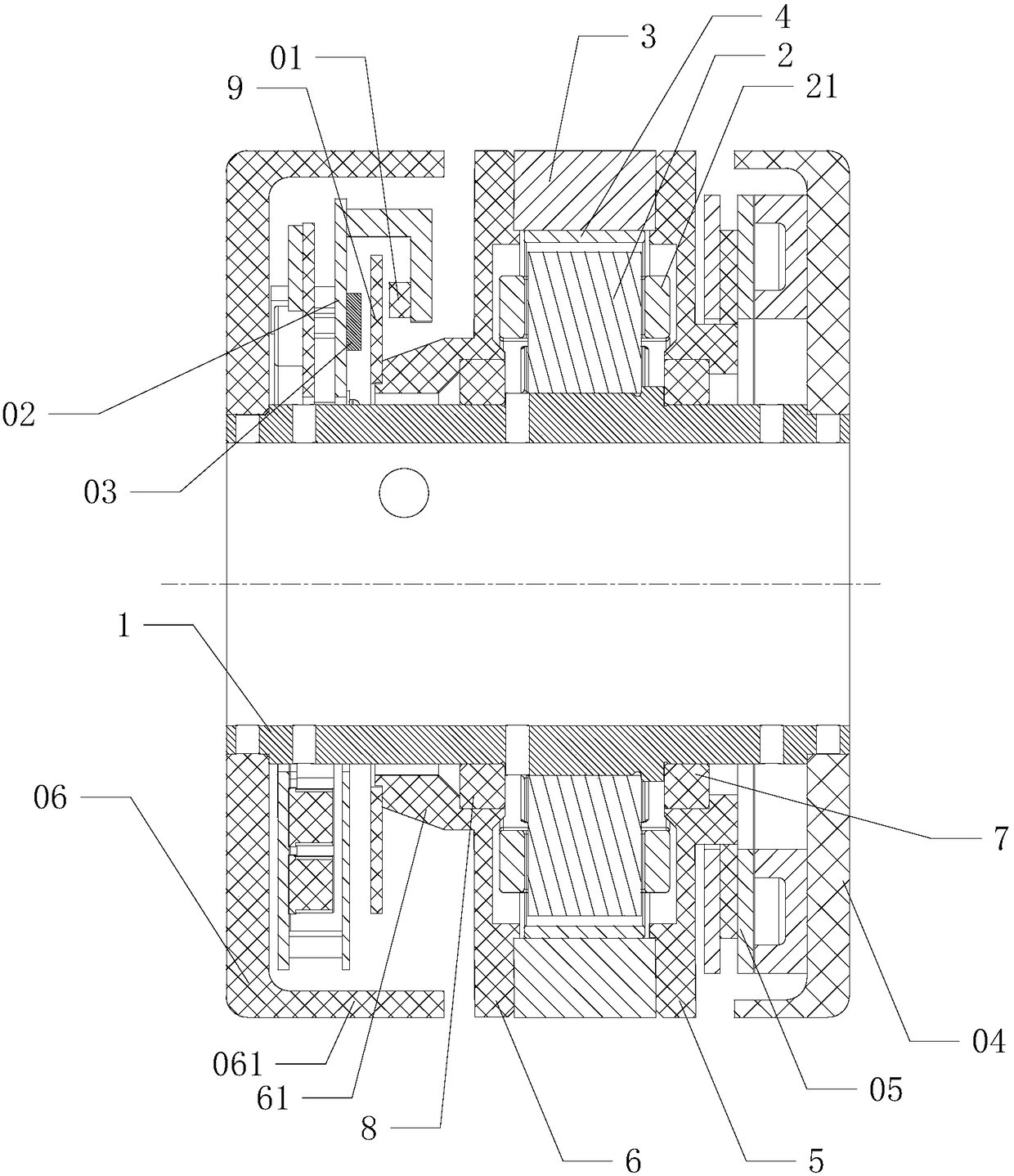

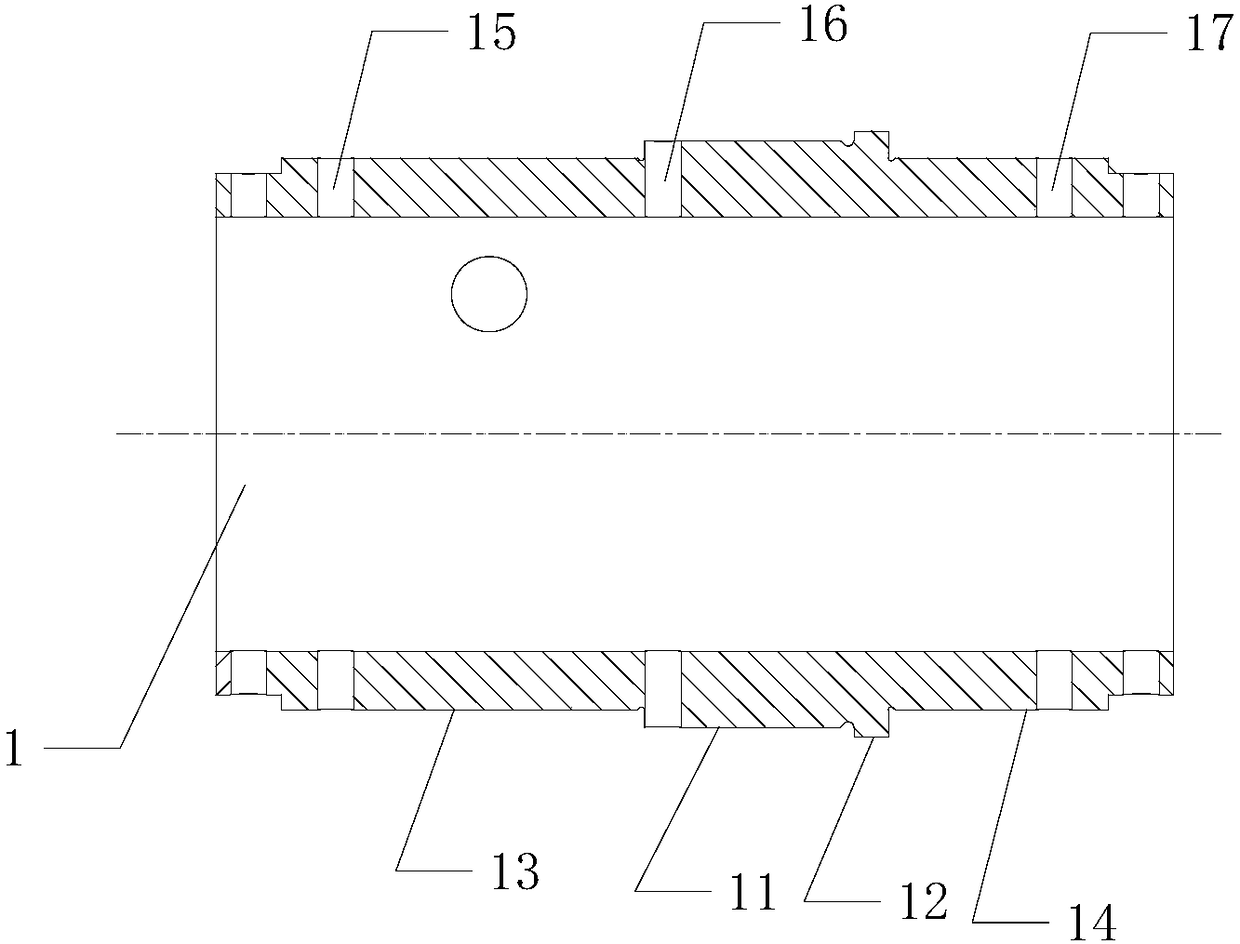

[0031] Attached below Figure 1~2 The present invention will be further described.

[0032] A hollow high-torque servo motor, comprising a direct shaft 1, the direct shaft 1 is hollowly arranged, and the middle part of the direct shaft 1 is provided with a first annular step 11 in the front, and a stator core 2 is sleeved on the first annular step 11, and the stator iron core The circumference of the core 2 is wound with a stator coil 21, the outer side of the stator core 2 is provided with an inner rotor core 3, and the inner side of the inner rotor core 3 is magnetically bonded with a magnetic steel 4, and the inner rotor core 3 The two ends are fixed on the front end cover 5 and the rear end cover 6, and the front end cover 5 and the rear end cover 6 are rotatably supported on the straight shaft 1; the aspect ratio of the stator core 2 is between 0.5 and 3, and the inner rotor core 3 The width is greater than the width of the stator core 2, and the length of the first annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com