Cigar coated tobacco leaf sorting method

A technology of tobacco leaves and cigars, applied in the field of tobacco, can solve problems such as production chaos, low labor efficiency, waste of tobacco leaves, etc., and achieve the effects of improving production efficiency, reducing labor intensity, and avoiding waste of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

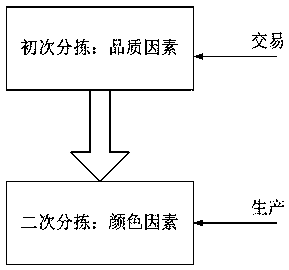

[0022] like figure 1 Said, the sorting method of the present invention comprises two steps.

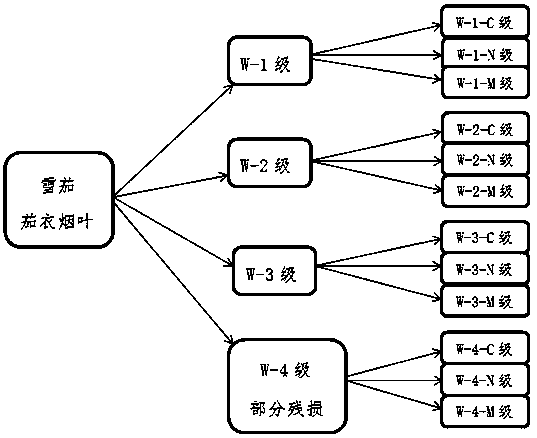

[0023] The first step is the initial sorting, which is carried out after the cigar-coated tobacco leaves are prepared and before aging, that is, when they are transferred to the cigar factory or before they are transferred to the cigar factory. Cigar wrapping leaves are sorted according to cigar leaf quality factors including: leaf size, leaf integrity and spread, leaf toughness (elasticity), leaf structure and identity, leaf veins thickness etc. Cigar-coated tobacco leaves are divided into 4 quality grades: Grade 1, Grade 2, Grade 3 and Partial Damage.

[0024] The second step is the secondary sorting, which is carried out after the alcoholization process of the cigar-coated tobacco leaves and before the production of the cigar factory (the closer to the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com