Single-piece beam leveler

A monolithic beam and leveling machine technology, which is applied in the field of leveling machines, can solve the problems of poor control of the degree of locking, failure to eliminate gaps, and affect leveling quality, and achieve easy adjustment, gap elimination, and guaranteed The effect of the leveling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

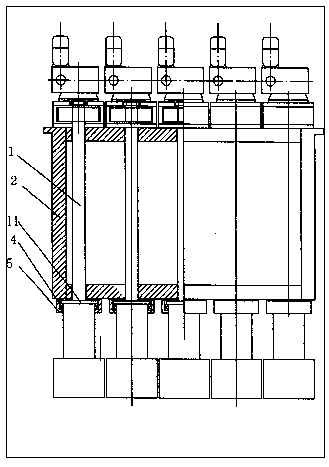

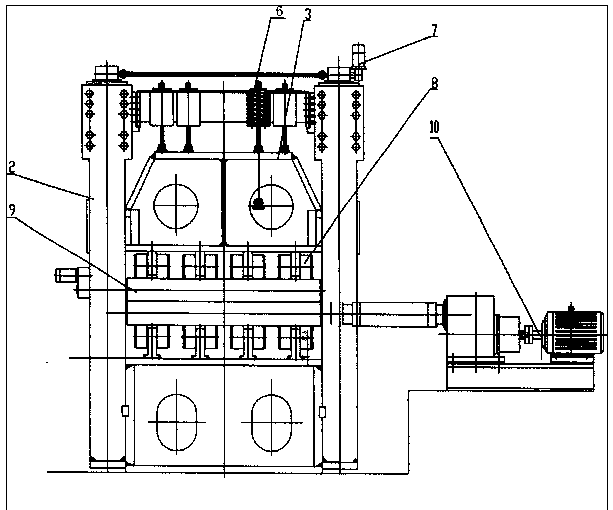

[0010] The present invention will be further described below in conjunction with the drawings. Such as figure 1 with figure 2 As shown, the present invention discloses a single-piece beam leveling machine, which includes a screw rod 1, a frame 2, a single-piece beam 3, a boss 11 is provided at the upper connecting beam between the screw rod and the frame, A pallet seat 5 is installed under the platform, and the pallet seat is connected with the upper part of the frame; each monolithic beam is provided with 1-6 sets of spring balance devices 6. A thrust bearing 4 or a sliding block can be installed under the boss. The screw rod can be divided into two upper and lower sections, and the two sections are connected by keys. figure 1 7 is the pressing mechanism, 8 is the support roller assembly, 9 is the work roll assembly, and 10 is the main transmission device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com