A liquid storage tank capable of simultaneously adjusting pressure and temperature

A technology for temperature regulation and liquid storage tanks, which is applied to tank cars, railway car body parts, transport passenger cars, etc., can solve problems such as unfavorable sustainable development, impact on the ecological environment, and increase storage costs, so as to achieve sustainable development and ecological protection. The effect of environmental protection and saving storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

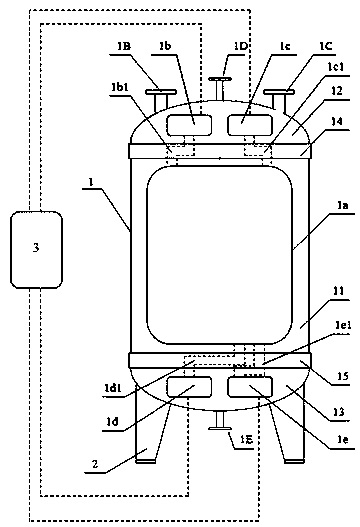

[0021] Such as figure 1 As shown, a liquid storage tank capable of simultaneously adjusting pressure and temperature is composed of a tank body 1 and a fixing part 2 located below the tank body 1. The bottom 13 in the shape of a circular arc cover, and the middle part 11 in the shape of a hollow cylinder between the top 12 and the bottom 13; the middle part 11 and the bottom 13 are connected by welding, and the welding area between the middle part 11 and the bottom 13 The lower welding reinforcement 15 is connected by welding between the middle part 11 and the top 12, and an upper welding reinforcement 14 is arranged on the periphery of the welding area between the middle part 11 and the top 12; the upper welding reinforcement 14 and the lower welding reinforcement 15 are in the tank body 1 protrudes radially to ensure a firm connection between the middle and the top of the tank, and between the middle and the bottom, while ensuring internal sealing and improving the strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com