Travelling transporter and storage cabinet

A technology of conveying device and storage unit, which is applied in the field of cargo storage, can solve the problems of high labor intensity, energy consumption, and low work efficiency, and achieve the effect of convenient transportation, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

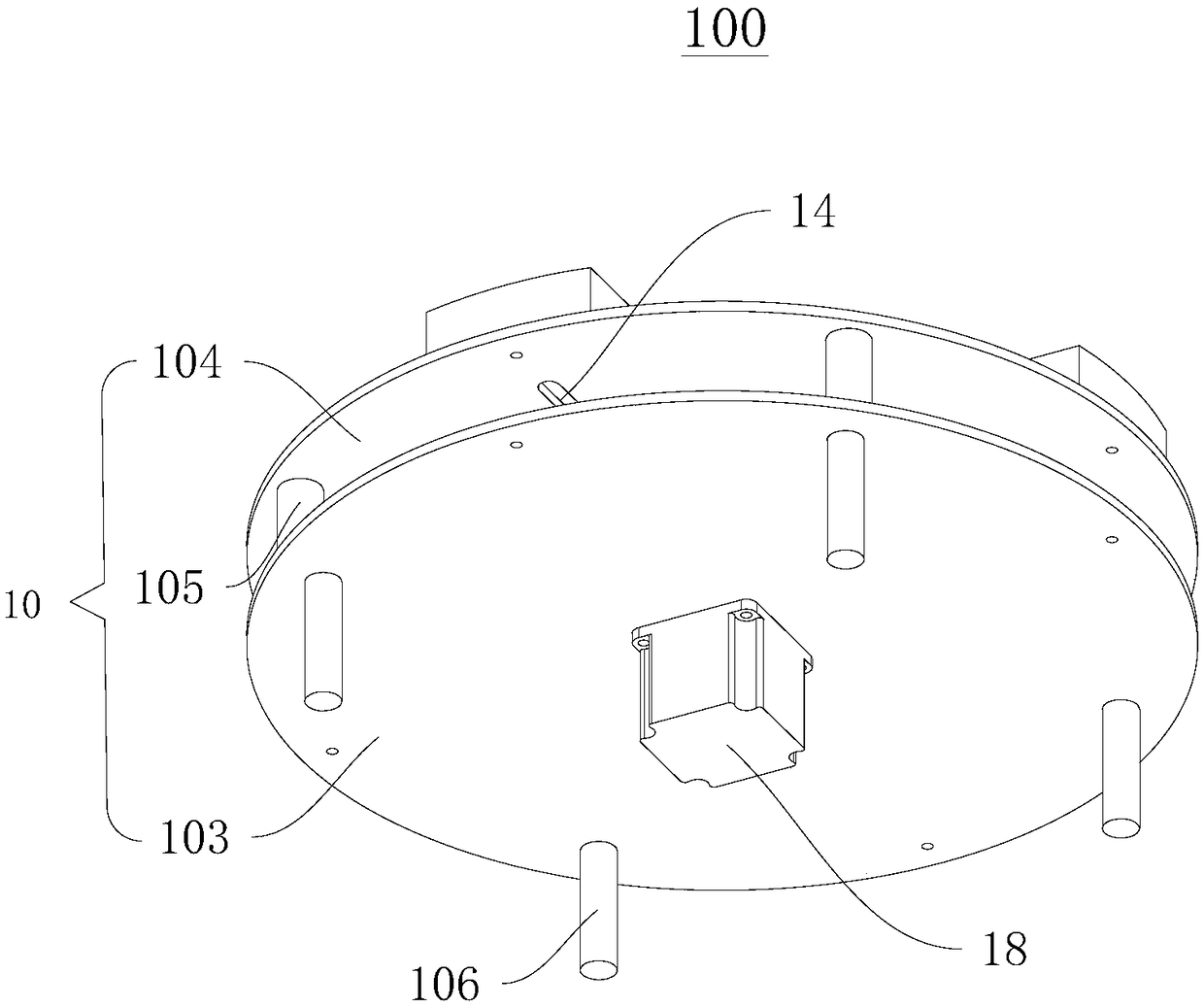

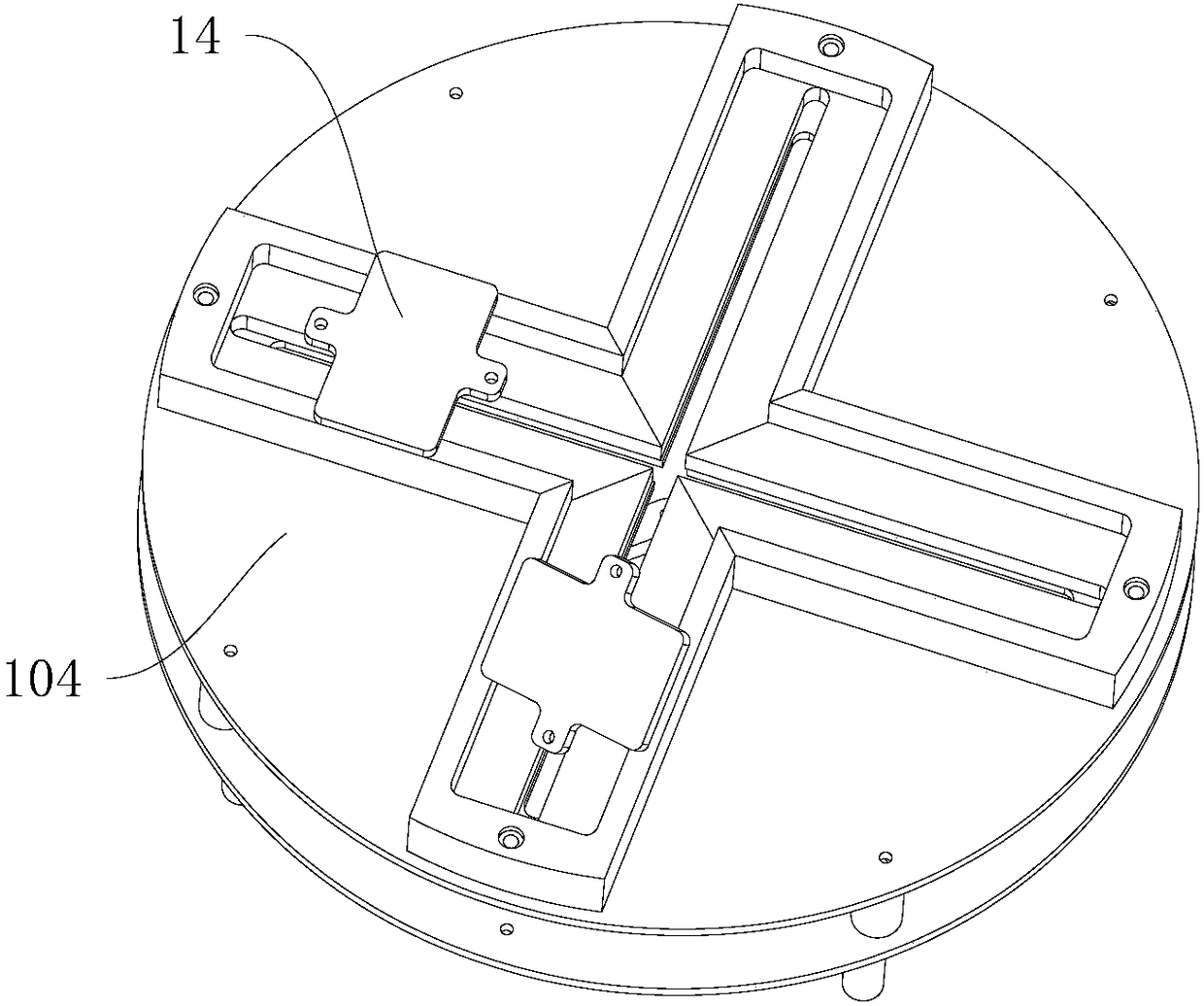

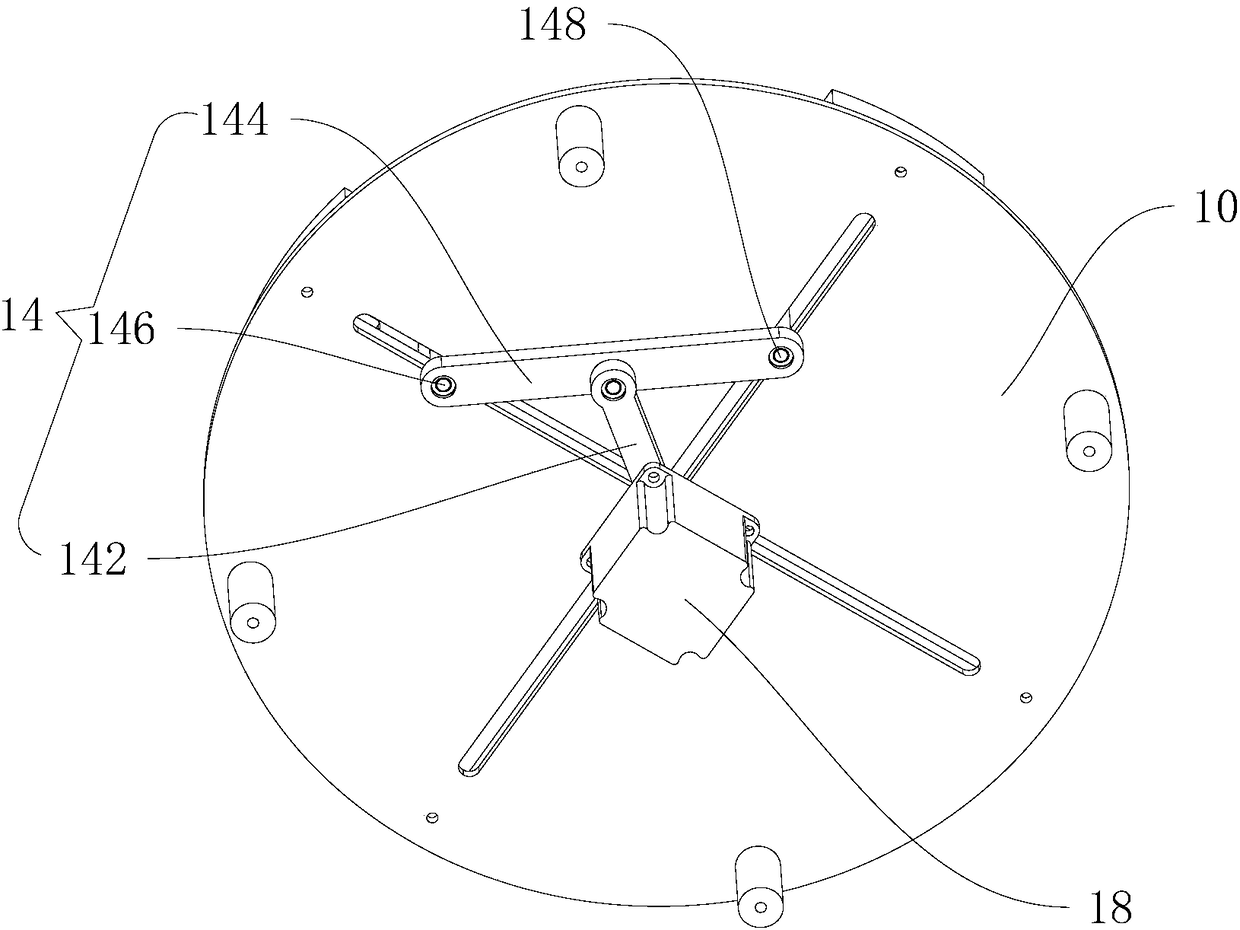

[0042] figure 1 It is a structural schematic diagram of the first viewing angle of the walking conveying device 100 provided in this embodiment, figure 2 A schematic structural diagram of the second viewing angle of the walking conveying device 100 provided in this embodiment. Please refer to figure 1 and figure 2 shown.

[0043] The walking conveyor 100 includes a base 10 , a slider crank mechanism 14 and a power source 18 . The base 10 is provided with slide rails. The crank slider mechanism 14 is disposed on the base 10 and the slider is slidably disposed in the slide rails. The power source 18 is fixedly disposed on the base 10 and drives the crank 142 to rotate.

[0044] Please continue to refer to figure 1 As shown, the base 10 includes a base 103, a walking table 104 and a connecting column 105, the base 103 and the walking table 104 are arranged in parallel, the connecting column 105 is located between the base 103 and the walking table 104 and connects the base...

Embodiment 2

[0062] Embodiment 2 of the present invention provides a storage cabinet 200 , which includes a cabinet body 20 and the walking conveying device 100 provided in Embodiment 1. The walking conveying device 100 is located inside the bottom of the cabinet body 20 .

[0063] Figure 5 It is a schematic structural diagram of the storage cabinet 200 provided in Embodiment 2, Image 6 A schematic structural diagram of the cabinet body 20 in the storage cabinet 200 provided in the second embodiment. Please refer to Figure 5 and Image 6 shown.

[0064] The cabinet body 20 is a columnar structure, and its projection on the horizontal plane is a cross-shaped structure and includes two lockers. The two lockers are intersected to form four storage areas, wherein the first slide rail in Embodiment 1 107 is located in one of the lockers, the second slide rail 108 is located in the other locker, and the walking conveyor 100 slides along the first slide rail 107 and the second slide rail 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com