Elevator car damping structure

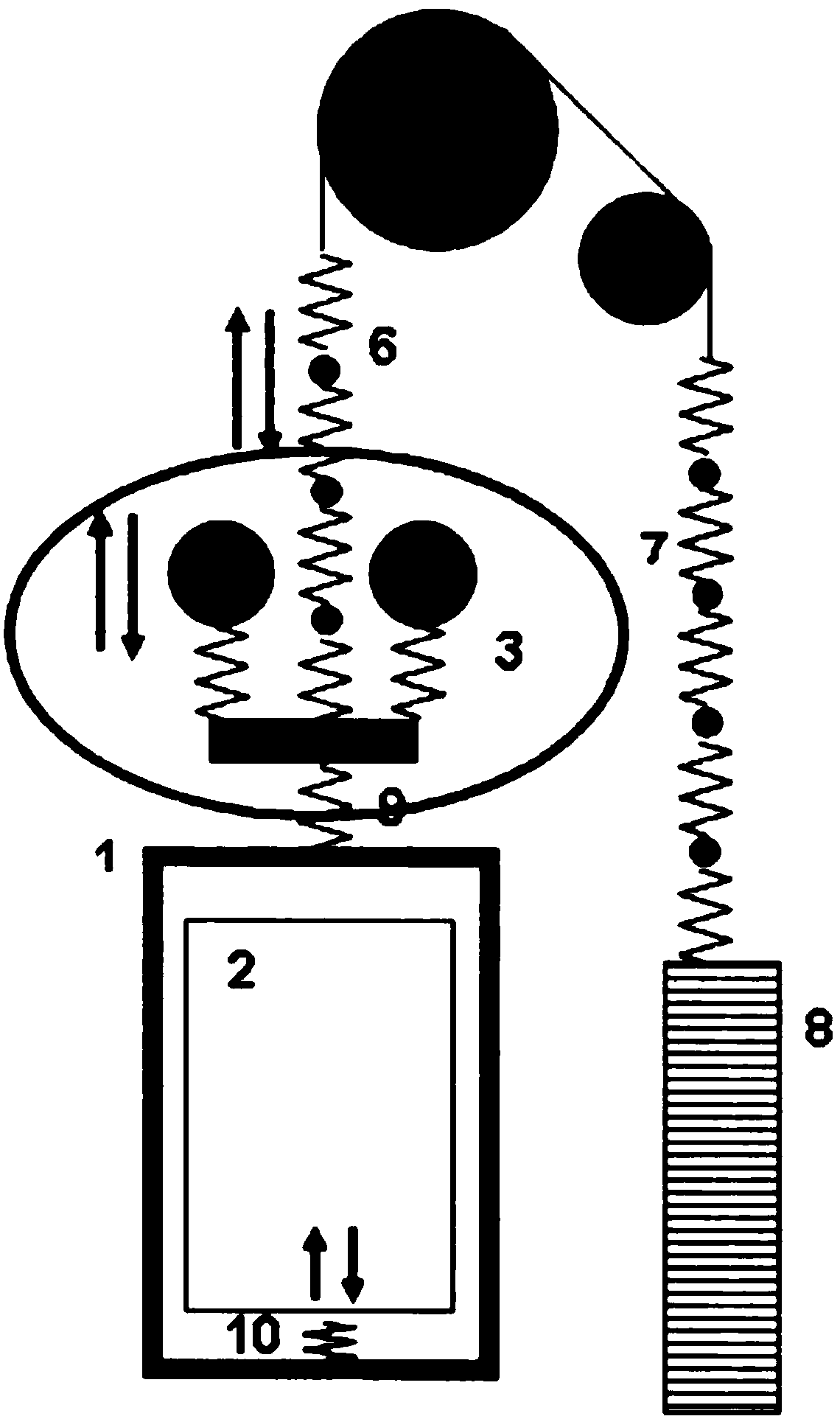

An elevator car and car technology, applied in the field of elevator car shock absorption, can solve the problems of personal safety hazards, poor car shock absorption capacity, subsidence, etc., to improve deformation resistance and shock absorption capacity, and reduce overweight feeling , the effect of reducing the feeling of weightlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

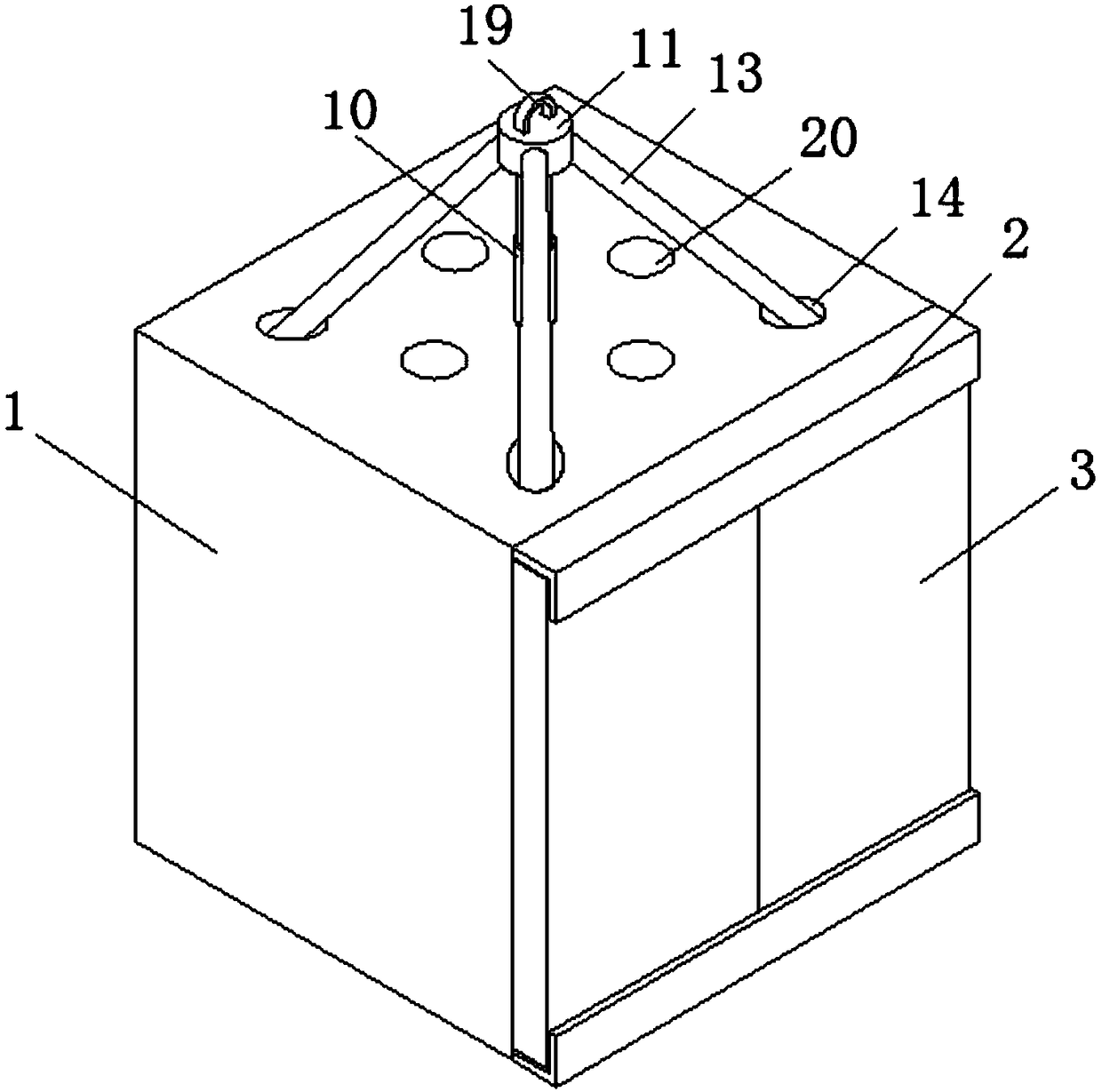

Embodiment 1

[0041] Such as Figure 3-4 A shock-absorbing structure for an elevator car shown includes a car body 1, the front top and bottom of the car body 1 are provided with slide rails 2, and the front of the car body 1 is located on the slide rails. 2 are slidingly connected with two groups of compartment doors 3 that cooperate with each other. The car body 1 includes an outer shell 4 and an inner shell 5, and a cavity 6 is provided between the outer shell 4 and the inner shell 5. Inside the cavity 6 Filled with damping spring sheets 7, the inner bottom of the inner shell 5 is fixedly installed with a car liner 9 through a spring shock absorber 8, and a hydraulic shock absorber 10 is fixedly installed at the middle part of the top of the outer shell 4, and The top of the hydraulic shock absorber 10 is integrally equipped with a connecting block 11, a fixed block 12 is slidably connected to the top corner of the inner shell 5, and a support rod 13 is hinged between the fixed block 12 ...

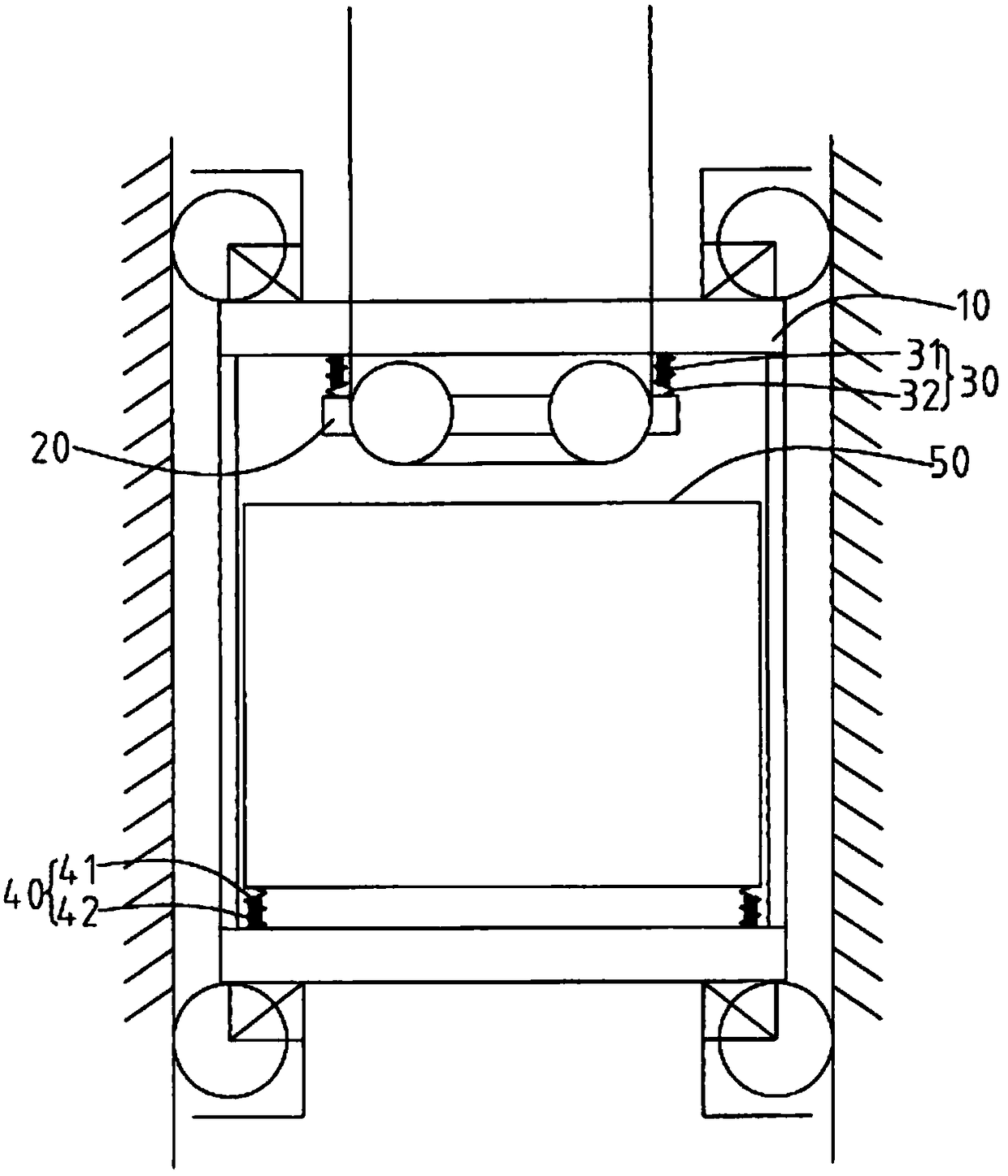

Embodiment 2

[0056] A shock absorbing structure for an elevator car, comprising a car body 1, the front top and bottom of the car body 1 are provided with slide rails 2, and the front of the car body 1 is located between the slide rails 2 There are two groups of car doors 3 that cooperate with each other in sliding connection. The car body 1 includes an outer shell 4 and an inner shell 5, and a cavity 6 is provided between the outer shell 4 and the inner shell 5, and the cavity 6 is filled with reducing Vibrating spring sheet 7, the inner bottom end of the inner shell 5 is fixedly installed with a car liner 9 through a spring shock absorber 8, and a hydraulic shock absorber 10 is fixedly installed at the middle part of the top of the outer shell 4, and the hydraulic shock absorber The top of the device 10 is integrally installed with a connecting block 11, the top corner of the inner shell 5 is slidably connected with a fixed block 12, and a support rod 13 is hinged between the fixed block ...

Embodiment 3

[0066] A shock absorbing structure for an elevator car, comprising a car body 1, the front top and bottom of the car body 1 are provided with slide rails 2, and the front of the car body 1 is located between the slide rails 2 There are two groups of car doors 3 that cooperate with each other in sliding connection. The car body 1 includes an outer shell 4 and an inner shell 5, and a cavity 6 is provided between the outer shell 4 and the inner shell 5, and the cavity 6 is filled with reducing Vibrating spring sheet 7, the inner bottom end of the inner shell 5 is fixedly installed with a car liner 9 through a spring shock absorber 8, and a hydraulic shock absorber 10 is fixedly installed at the middle part of the top of the outer shell 4, and the hydraulic shock absorber The top of the device 10 is integrally installed with a connecting block 11, the top corner of the inner shell 5 is slidably connected with a fixed block 12, and a support rod 13 is hinged between the fixed block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com